IM 986-2 / Page 19 of 48

10% 20% 30% 40% 50%

Cooling Capacity 0.9910 0.9510 – – –

Heating Capacity 0.9950 0.9600 – – –

Pressure Drop 1.0350 0.9600 – – –

10% 20% 30% 40% 50%

Cooling Capacity 0.9980 0.9720 – – –

Heating Capacity 0.9950 0.9700 – – –

Pressure Drop 1.0230 1.0570 – – –

10% 20% 30% 40% 50%

Cooling Capacity 0.9900 0.9800 0.9700 0.9600 0.9500

Heating Capacity 0.9870 0.9750 0.9620 0.9420 0.9300

Pressure Drop 1.0700 1.1500 1.2500 1.3700 1.4200

10% 20% 30% 40% 50%

Cooling Capacity 0.9950 0.9920 0.9870 0.9830 0.9790

Heating Capacity 0.9910 0.9820 0.9770 0.9690 0.9610

Pressure Drop 1.0700 1.1300 1.1800 1.2600 1.2800

Table 5: Antifreeze Correction Factors

Ethylene Glycol

Propylene Glycol

Methanol

Ethanol

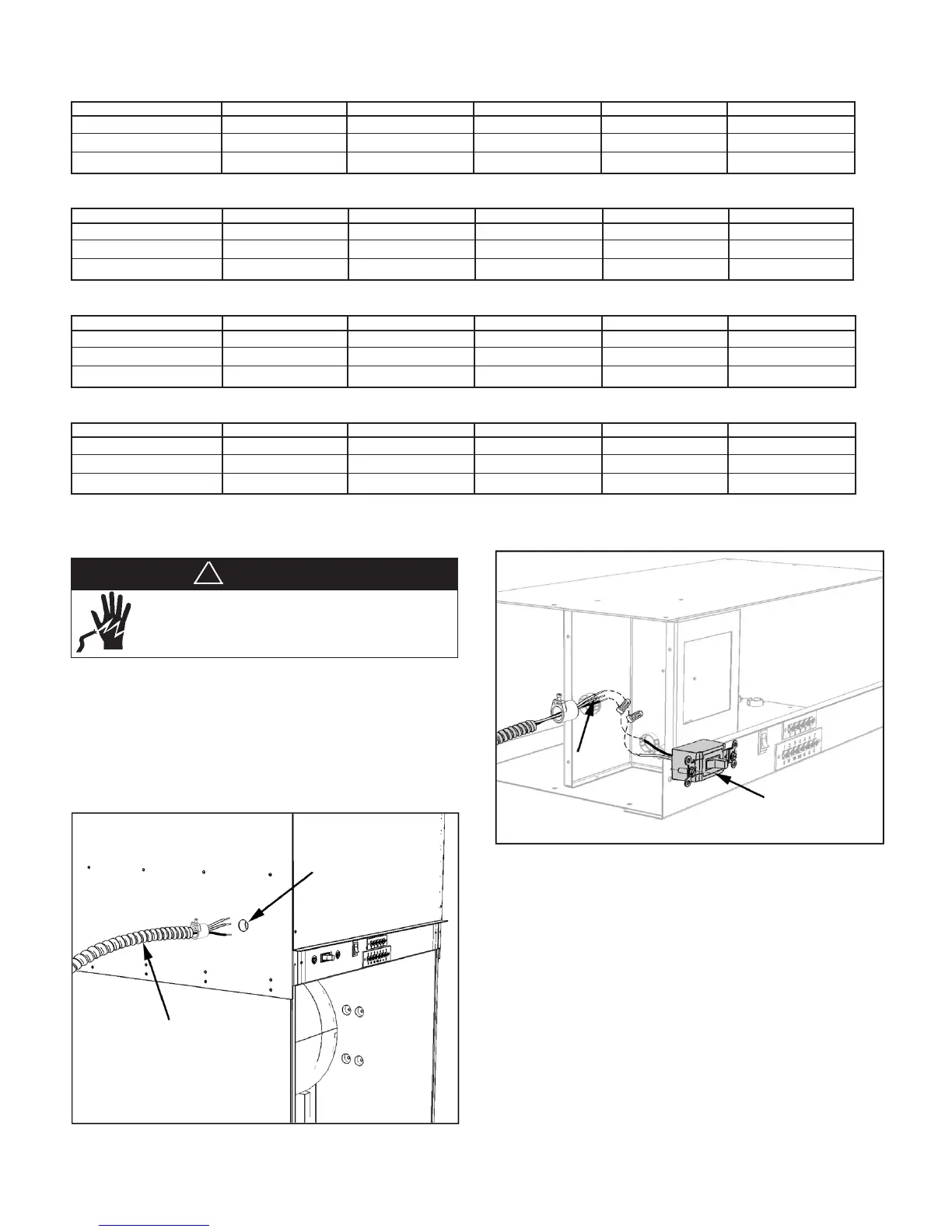

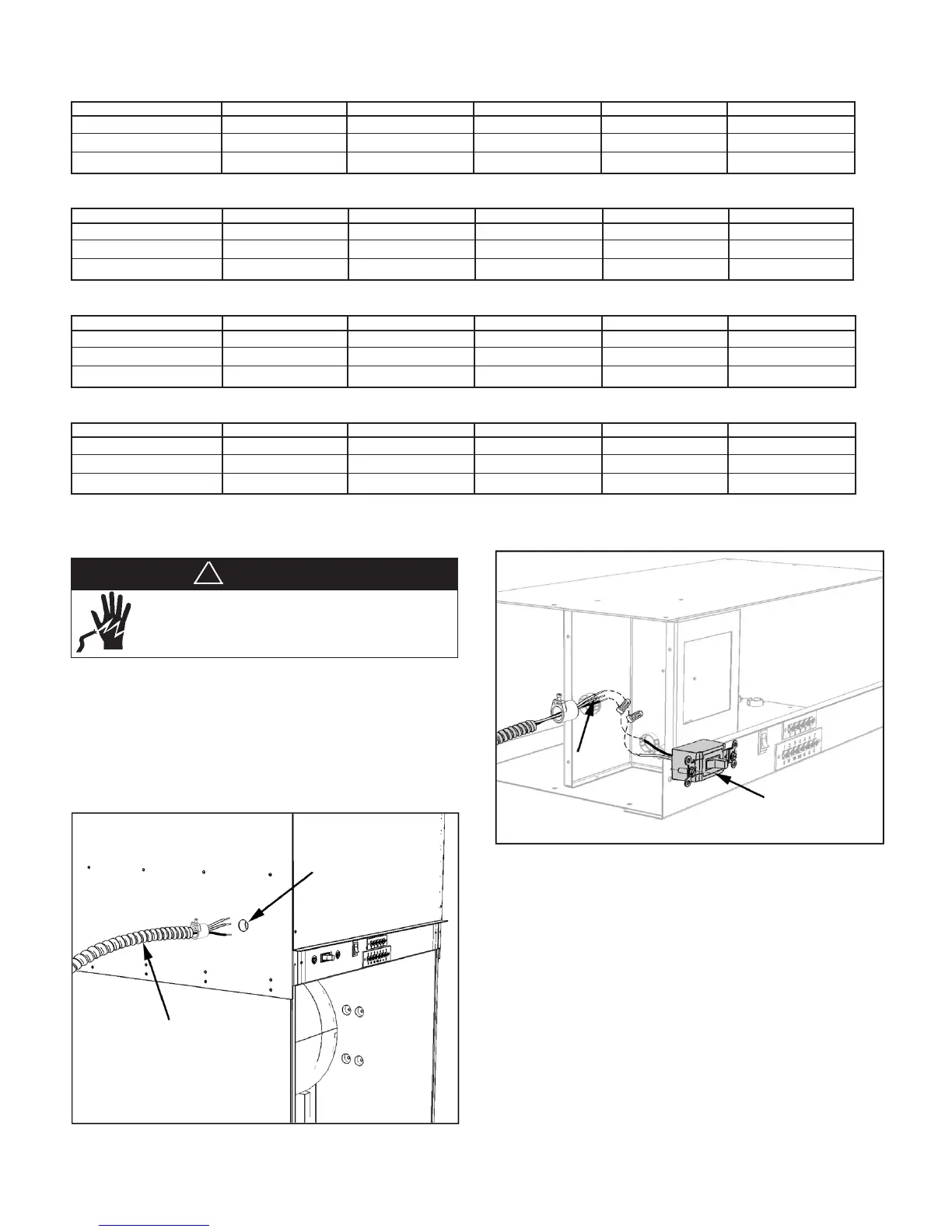

Power Wiring From Building to Unit

1. Locate the electrical power supply wiring from the

building and feed wiring through the 1/2" conduit

tting (strain relief) on the unit as shown in Figure

27 & 28, following local electrical codes and

regulations.

Figure 27: Supply Electric Wiring from Building to Unit

Figure 28: Wire to Unit Switch

2. If a remote wall-mounted thermostat is being used,

install a 24-volt thermostat wiring cable with at

least 6 wires from the unit low voltage terminal strip

(Figure 29) to the thermostat location.

3. If a wireless remote thermostat was ordered to

control the unit, it is recommended that the Remote

Control Node (RCN) be installed now.

Flexible Metal Conduit &

Strain Relief

1/2" Knockout for

Supply Wiring

DANGER

To avoid electrical shock, personal injury or death:

1. Installer must be qualied, experienced technician.

2. Disconnect power supply before installation to prevent

electrical shock and damage to equipment.

!

Loading...

Loading...