4-23

4.8.15 Check Valve

●Replacement method

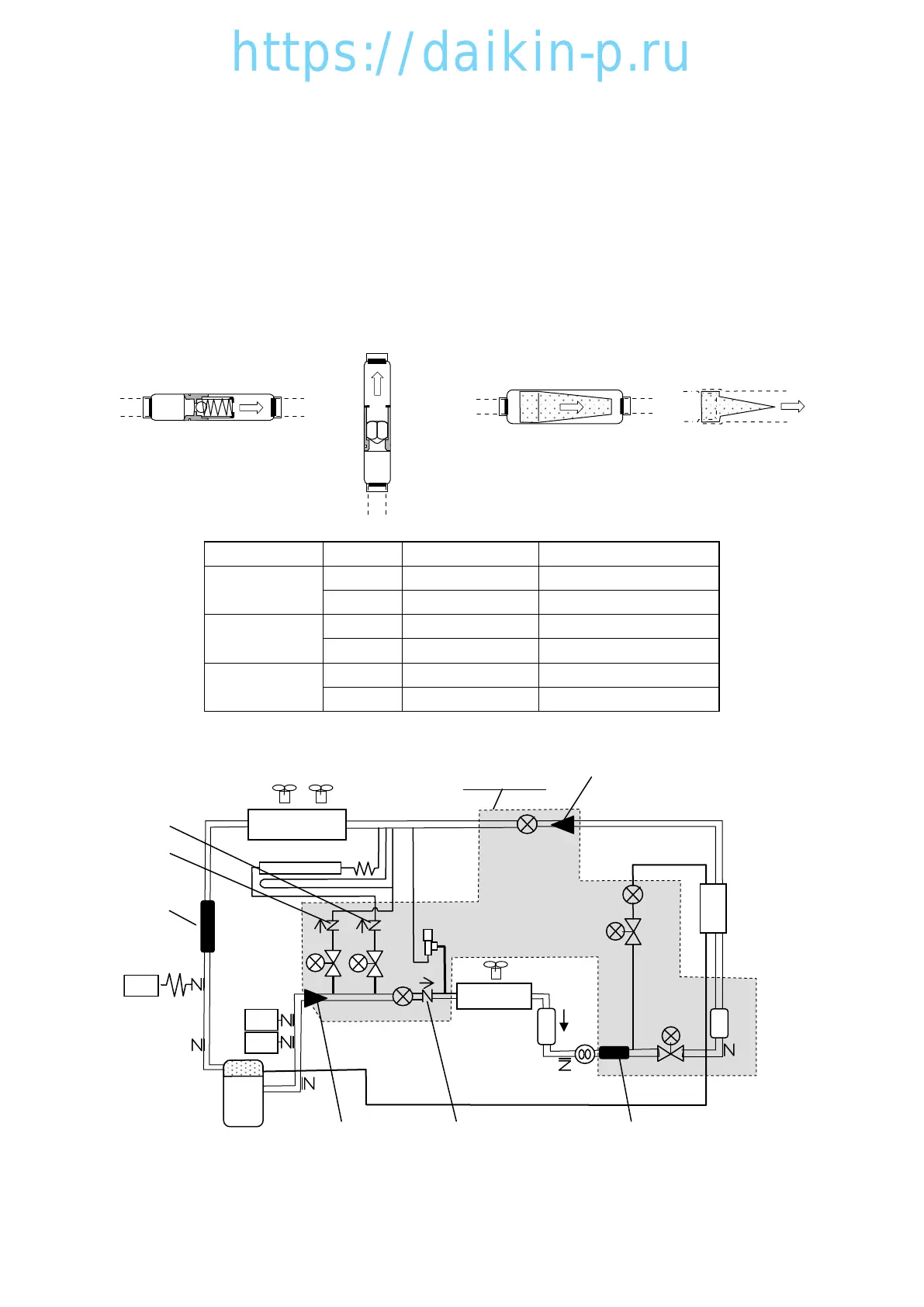

1. Refer location of check valves to below picture.

2. Do not make any mistake about the installation

direction (arrow direction) of the check valve

3. While brazing, keep valve cool below 120℃

(248

F

) with wet cloth.

4. Check if there is no gas leakage after completion

of brazing.

4.8.16 Filter and Strainer

●Replacement method

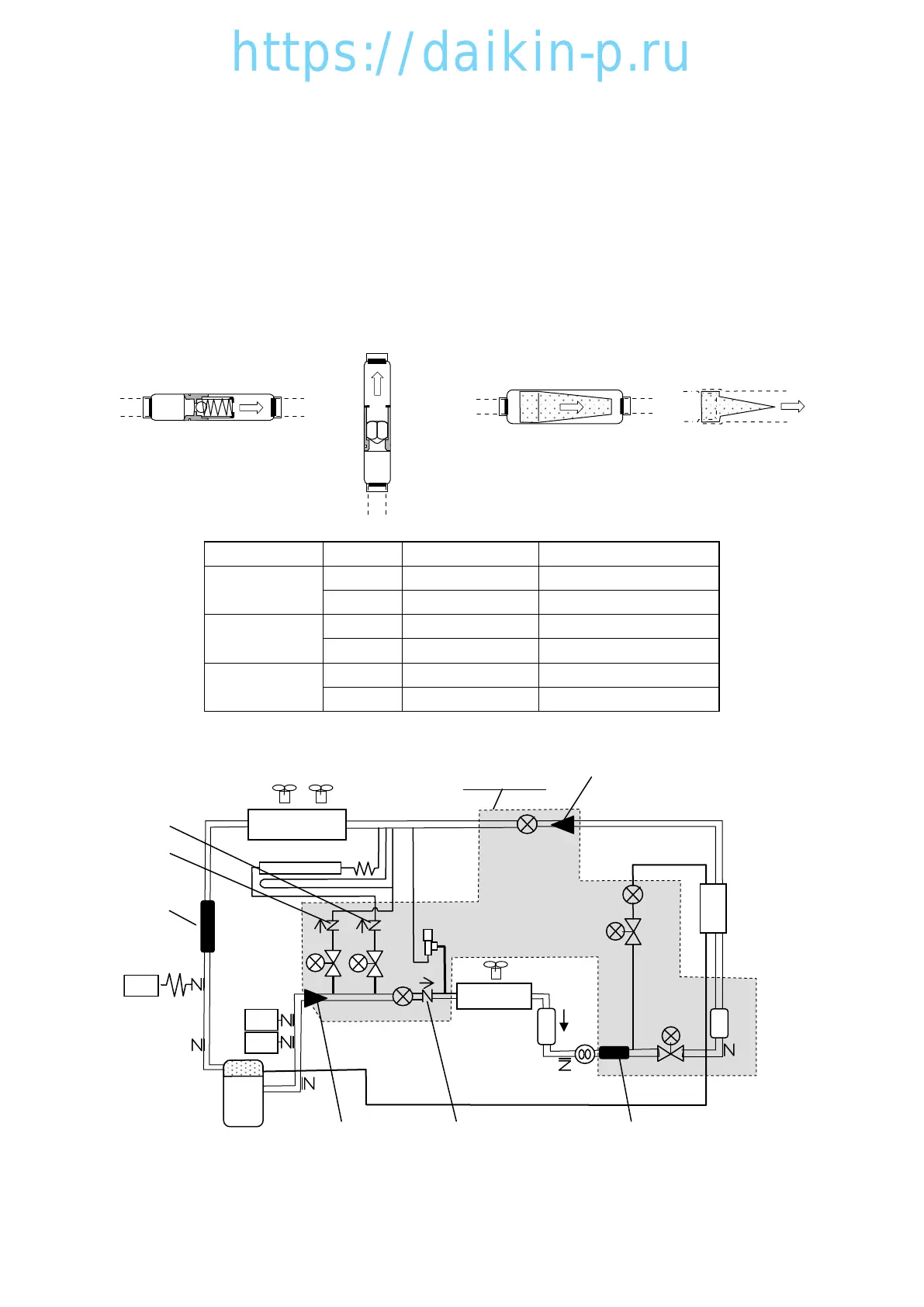

1. Refer location of check valves to below picture.

2. Install the new check valve in the direction which

an arrow shows.

3. Check if there is no gas leakage after completion

of brazing.

⑥⑦Strainer④⑤Filter①Check valve (Spring type)

②③Check valve (No spring type)

Valve chamber

Economizer

Reheat coil (option)

Receiver

Compressor

HPT

HPS

EMV

ESV

LSV

Dryer

EEV

LPT

Sight glass

CFM

EFM

RSVHSV

PRV

DMV

⑦

①⑤⑥

Evaporator

Condenser

③

②

④

Name No. Size Application

Check valve

① 5/8, φ15.9 DMV outlet

②③ 3/8, φ9.5 HSV, RSV outlet

Filter

④ 1-1/4, 31.8φ Compressor inlet

⑤ 1/2, 12.7φ LSV, ESV inlet

Strainer

⑥ 5/8, 15.9φ DMV, HSV, RSV inlet

⑦ 1/2, 12.7φ EEV inlet

0401-26LX10F11BEn.indd4-230401-26LX10F11BEn.indd4-23 2014/11/1916:42:292014/11/1916:42:29

Loading...

Loading...