3-8

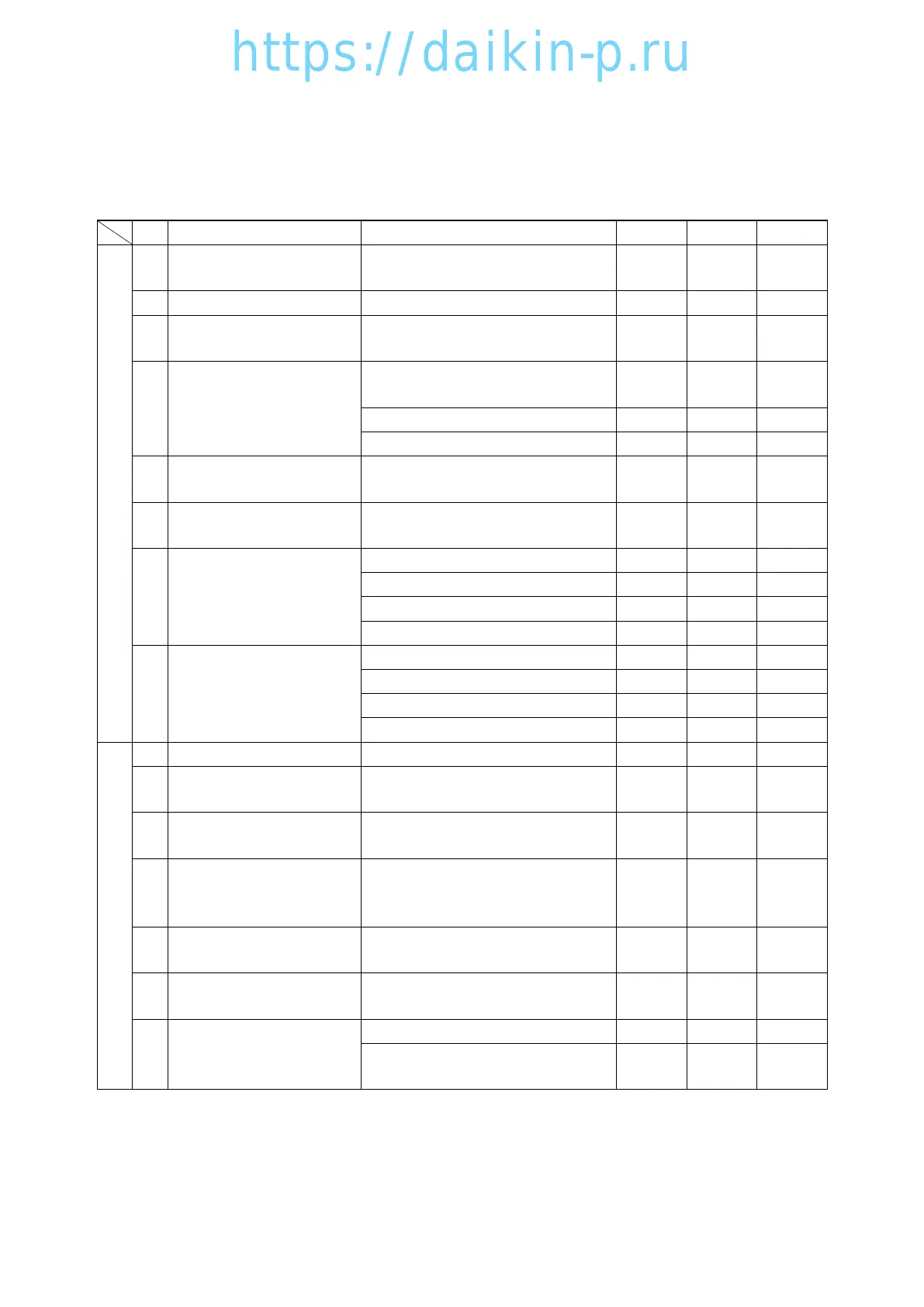

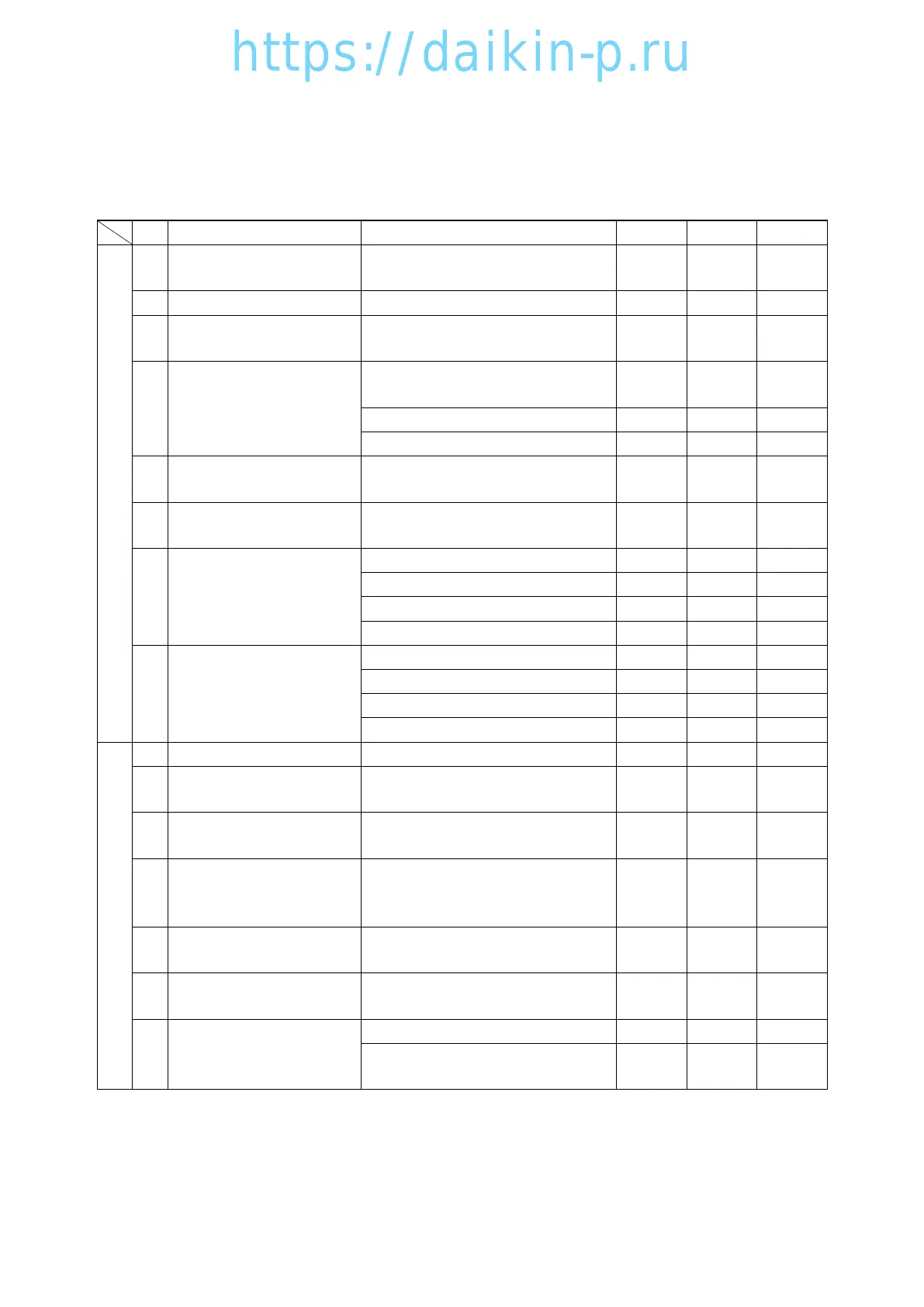

3.4 Periodic Inspection

Always to operate the unit normally, periodic inspections for each parts are required in order to confirm the

unit condition and maintenance separately pre-trip inspection.

The following table shows an example of the inspection plan.

No. Inspection item Inspection content 2nd year 4th year 8th year

General structure

1

Inspection for physical

damage

✓✓✓

2 Loose mounting bolts ✓✓✓

3

Condition of panels, hinge

and lock

✓✓✓

4

Control box and

Inverter box inspection

1) Cover packing inspection and

replacement

✓✓✓

2) Loose cable gland ✓✓✓

3) Internal cleaning ✓✓✓

5

Air leakage from unit

casing

Air leakage and clearance ✓✓✓

6

Seal inspection and

replacement

Ventilator cover packing ✓✓✓

7

Painted area recondition

(Touch-up paint)

1) Compressor ✓✓✓

2) Receiver ✓✓✓

3) Solenoid valve (coil cover) ✓✓✓

4) Unit ✓✓

8 Repainting

1) Compressor ✓

2) Receiver ✓

3) Condenser fan motor ✓

4) Condenser fan ✓

Refrigerant system

1 Refrigerant leakage ✓✓✓

2 Compressor

Water entering to compressor

electrical terminal

✓✓✓

3

Inspection and replacement

of sight glass

✓

4

Condition of cramp on

the refrigerant pipes and

gauge pipes

✓✓✓

5

Condition of thermal

insulation of refrigerant pipe

✓✓✓

6

Evaporator coil cleaning

(by water)

✓✓✓

7 Condenser coil cleaning

1) Water-cleaning ✓✓✓

2) Steam-cleaning (after pumping

down the refrigerant)

✓✓✓

0301-10LX10F11BEn.indd3-80301-10LX10F11BEn.indd3-8 2014/11/1916:36:372014/11/1916:36:37

Loading...

Loading...