5 Installation

Installation and operation manual

13

RXYSQ8~12TMY1B

VRV IV-S system air conditioner

4P400263-1F – 2017.02

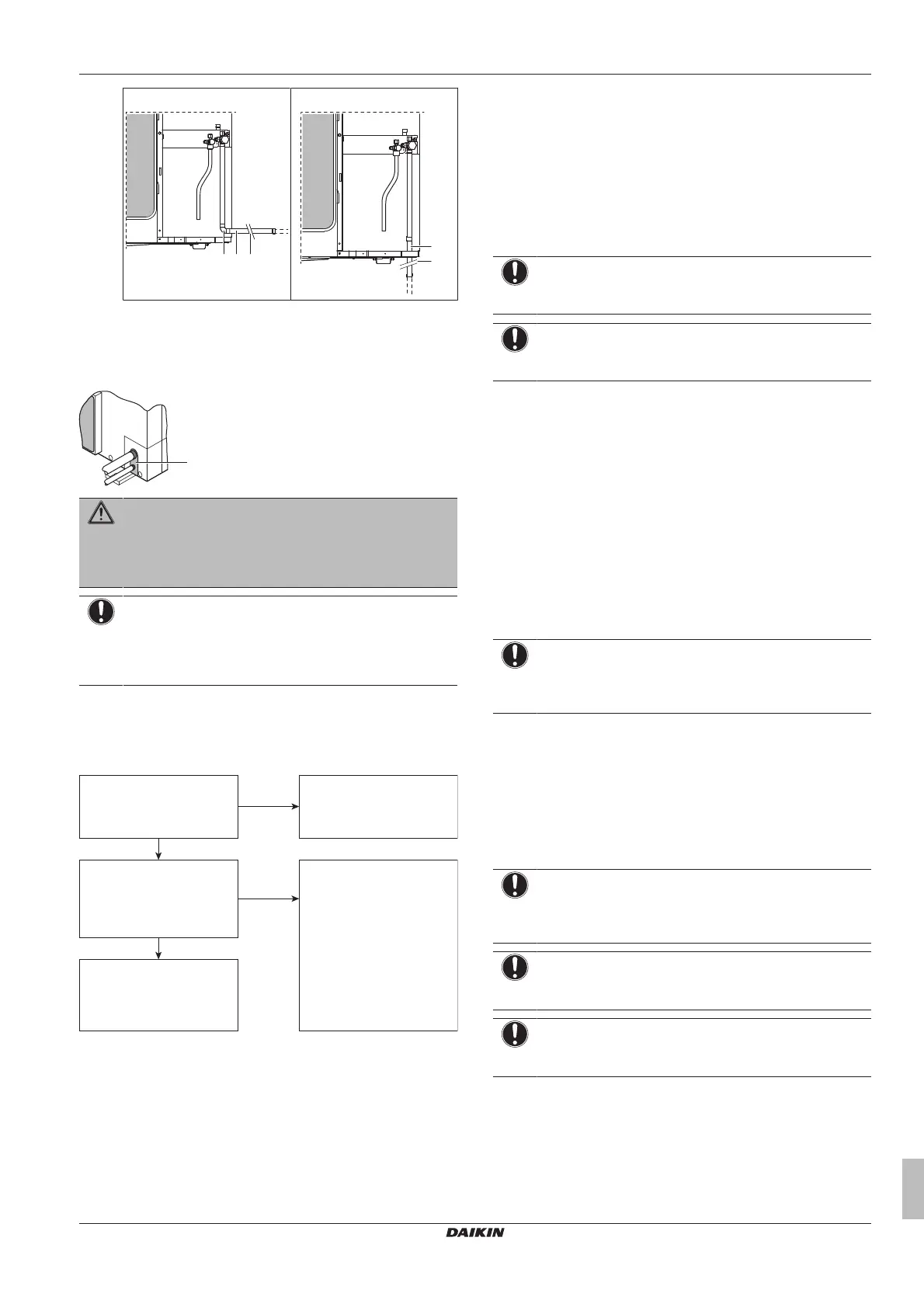

Possibility 3: To the side

Possibility 4: Downwards

5 Reattach the service cover and the piping intake plate.

6 Seal all gaps (example: a) to prevent snow and small animals

from entering the system.

WARNING

Provide adequate measures to prevent that the unit can be

used as a shelter by small animals. Small animals that

make contact with electrical parts can cause malfunctions,

smoke or fire.

NOTICE

Make sure to open the stop valves after installing the

refrigerant piping and performing vacuum drying. Running

the system with the stop valves closed may break the

compressor.

5.4 Checking the refrigerant piping

5.4.1 About checking the refrigerant piping

Refrigerant piping works are

finished?

The indoor units and/or

outdoor unit were already

powered ON?

Use procedure:

"Method 2: After power ON".

Finish piping work.

Use procedure:

"Method 1: Before power ON

(regular method)".

Yes

No

No

Yes

It is very important that all refrigerant piping work is done before the

units (outdoor or indoor) are powered on.

When the units are powered on, the expansion valves will initialise.

This means that they will close. Leak test and vacuum drying of field

piping and indoor units is impossible when this happens.

Therefore, there will be explained 2 methods for initial installation,

leak test and vacuum drying.

Method 1: Before power ON

If the system has not yet been powered on, no special action is

required to perform the leak test and the vacuum drying.

Method 2: After power ON

If the system has already been powered on, activate setting [2‑21]

(refer to "6.1.4 To access mode 1 or 2" on page 20). This setting

will open field expansion valves to guarantee a R410A piping

pathway and make it possible to perform the leak test and the

vacuum drying.

NOTICE

Make sure that all indoor units connected to the outdoor

unit are powered on.

NOTICE

Wait until the outdoor unit has finished the initialisation to

apply setting [2‑21].

Leak test and vacuum drying

Checking the refrigerant piping involves:

▪ Checking for any leakages in the refrigerant piping.

▪ Performing vacuum drying to remove all moisture, air or nitrogen

in the refrigerant piping.

If there is a possibility of moisture being present in the refrigerant

piping (for example, water may have entered the piping), first carry

out the vacuum drying procedure below until all moisture has been

removed.

All piping inside the unit has been factory tested for leaks.

Only field installed refrigerant piping needs to be checked.

Therefore, make sure that all the outdoor unit stop valves are firmly

closed before performing leak test or vacuum drying.

NOTICE

Make sure that all (field supplied) field piping valves are

OPEN (not outdoor unit stop valves!) before you start leak

test and vacuuming.

For more information on the state of the valves, refer to

"5.4.3Checking refrigerant piping: Setup"on page14.

5.4.2 Checking refrigerant piping: General

guidelines

Connect the vacuum pump through a manifold to the service port of

all stop valves to increase efficiency (refer to "5.4.3 Checking

refrigerant piping: Setup"on page14).

NOTICE

Use a 2-stage vacuum pump with a non-return valve or a

solenoid valve that can evacuate to a gauge pressure of

–100.7kPa (−1.007bar)(5Torr absolute).

NOTICE

Make sure the pump oil does not flow oppositely into the

system while the pump is not working.

NOTICE

Do not purge the air with refrigerants. Use a vacuum pump

to evacuate the installation.

Loading...

Loading...