FC 300 Design Guide

How to Install

" Tightening torques

Tighten power, electrical, brake, and gro und

terminals with the following torques:

FC 300 Connections Torqu e ( N m )

Motor, electrical supply,

brake, DC Bus

2-3

1.5-2.2 lb-ft

Ground, 24 DC 2-3

Relay, DC filter feedback 0.5-0.6

0.35-0.45

lb-ft

" Final Set-Up and Test

To test the set-up and ensure that the adjustable frequency drive is running, follow these steps.

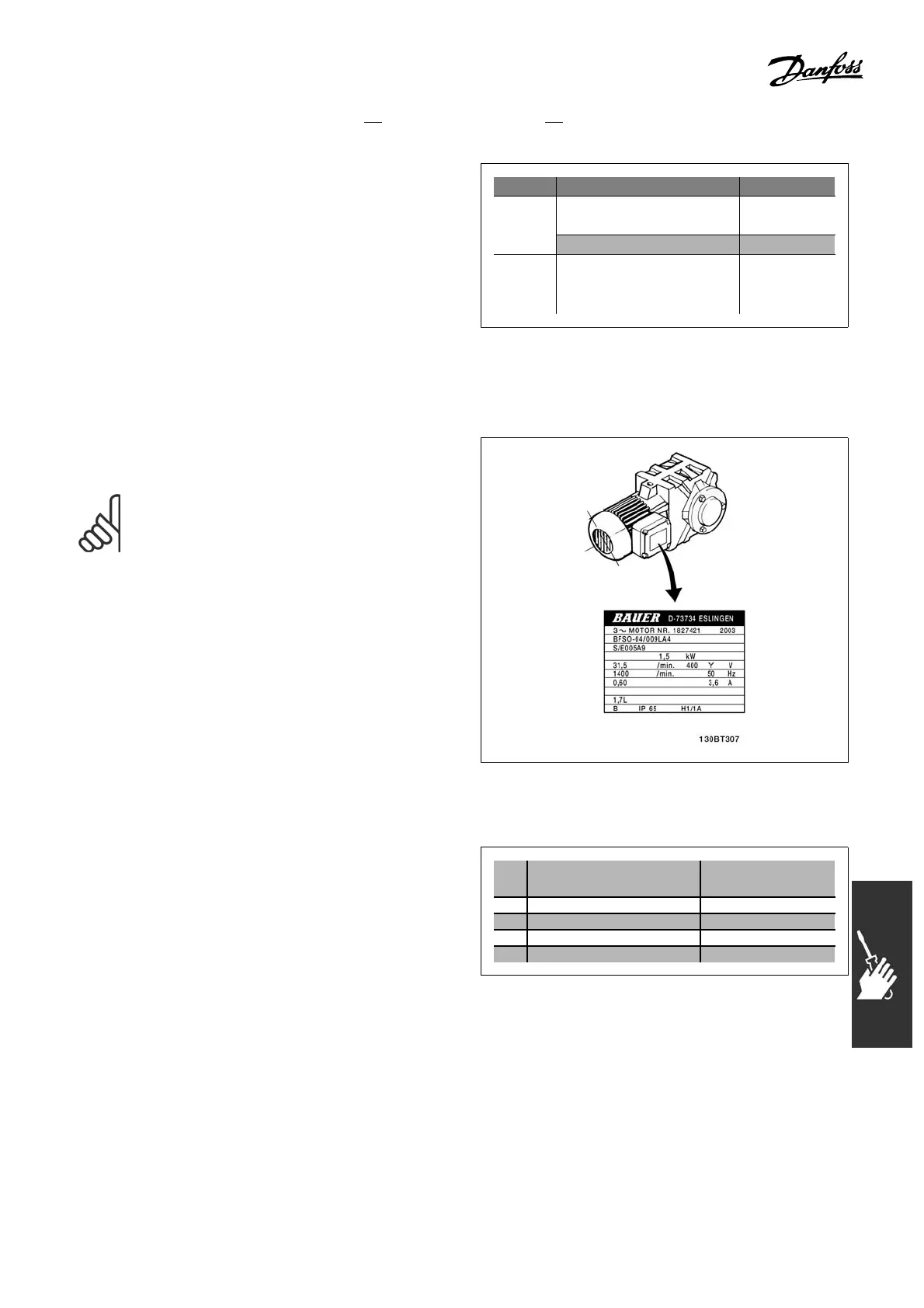

Step 1. Locate the motor nameplate.

NOTE

The motor is either star- (Y) or delta-

connected (∆). This information is located

on the motor nameplate data.

Step2. Enterthemotornamep

late data

in this parameter list.

To access this list, first p ress the [QUICK MENU]

key then select “Q2 Quick Se

tup”.

1. Motor Power [kW]

or Motor Power [HP]

par. 1-20

par. 1-21

2. Motor Voltage par. 1-22

3. Motor Frequency par. 1-23

4. Motor Current par. 1-24

5. Motor Nominal Speed par. 1-25

Step 3. Activate the Automatic Motor Adapta tion (AM A)

Performing an AMA will ensure optimum performance. The AMA measures the values

from the motor model equivalent diagram.

97

MG.33.B3.22 - VLT is a registered Danfoss trademark

Loading...

Loading...