4. Import and access the FC 301/FC 302 GSD le via

the path in the hardware catalog, see

Illustration 3.6.

Illustration 3.6 Import and Access the GSD File

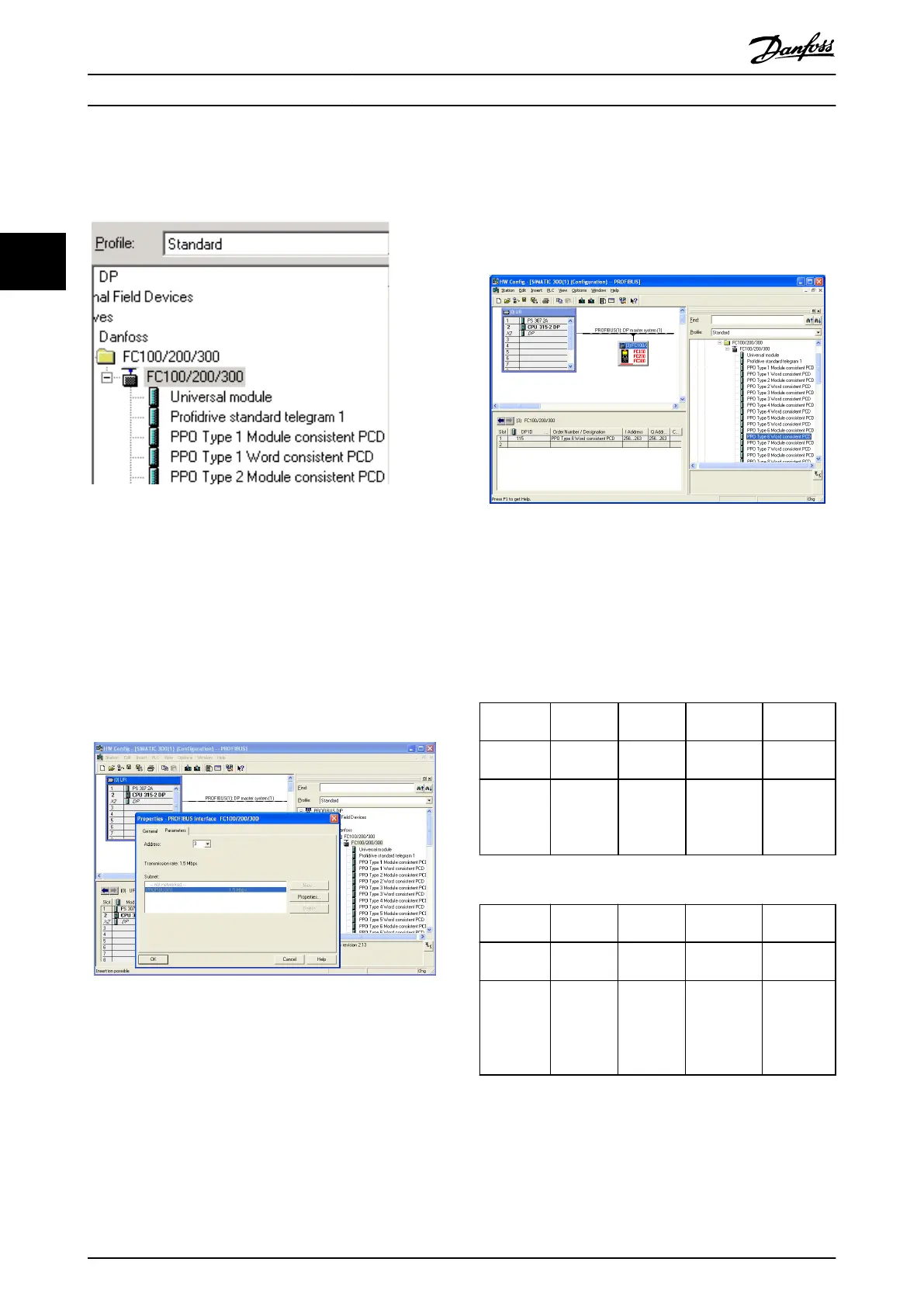

5. Open a project, set up the hardware, and add a

PROFIBUS master system.

6. Select FC 300, then drag and drop it onto the

PROFIBUS in the hardware diagram.

7. A window for the address of the FC 300 appears.

Select the address from the scroll-down list.

Ensure that the address setting matches the

previous address setting in parameter 9-18 Node

Address. See Illustration 3.7.

Illustration 3.7 Select the Address

8. Set up the peripheral input and output data. Data

set up in the peripheral area is transmitted

cyclically via PPO types. Drag and drop a PPO

type 6 word consistent to the rst slot, see

Illustration 3.8. See the PPO types in

chapter 4 Control for more information.

Illustration 3.8 Drag and Drop PPO Type 6 Word Consistent to

the First Slot

The conguration tool automatically assigns addresses in

the peripheral address area. In this example, the input and

output areas have the following congurations:

PPO type 6

PCD word

number

1 2 3 4

Input

address

256–257 258–259 260–261 262–263

Set-up STW MAV Parameter 9-

16 PCD Read

Congu-

ration.2

Parameter 9-

16 PCD

Read Cong-

uration.3

Table 3.3 PCD Read (Frequency Converter to PLC)

PCD word

number

1 2 3 4

Output

address

256–257 258–259 260–261 262–263

Set-up CTW MRV Parameter 9-

15 PCD Write

Congu-

ration.2

Parameter 9-

15 PCD

Write

Congu-

ration.3

Table 3.4 PCD Write (PLC to Frequency Converter)

Conguration

VLT

®

PROFIBUS DP MCA 101

10 Danfoss A/S © 01/2016 All rights reserved. MG37G202

33

Loading...

Loading...