batched. Therefore, when the master sends out a read/

write request, it must wait for the response before it sends

a new request. The request or response data value is

limited to maximum 4 bytes (see RC characteristics in

Table 5.14), which implies that text strings are not

transferable. For further information, see

chapter 7 Application Examples.

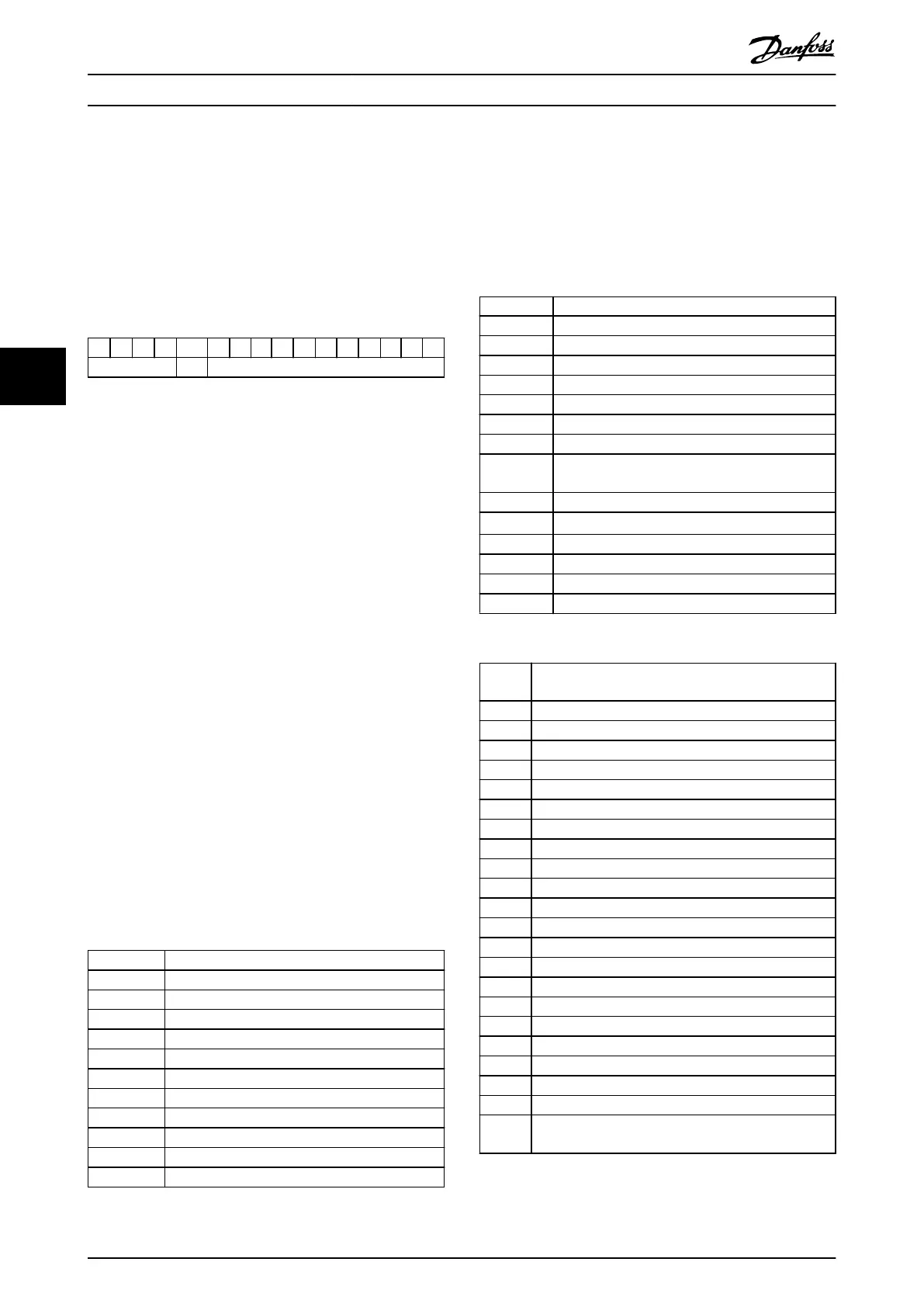

5.3.2 PCA - Parameter Characteristics

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

RC SMP PNU

Table 5.14 PCA - Parameter Characteristics

•

RC: Request/response characteristics (range 0–15).

•

SMP: Spontaneous message (not supported).

•

PNU: Parameter no. (range 1–1999).

5.3.3 Request/Response Handling

The RC portion of the PCA word denes:

•

The requests issued from the master to the slave.

•

Other portions of the PCV involved:

- PVA: The PVA portion transmits word-

size parameter values in bytes 7 and 8,

while long word size values require

bytes 5–8 (32 bits).

- IND: When the response/request

contains array elements, the IND carries

the array subindex. When parameter

descriptions are involved, the IND holds

the record subindex of the parameter

description.

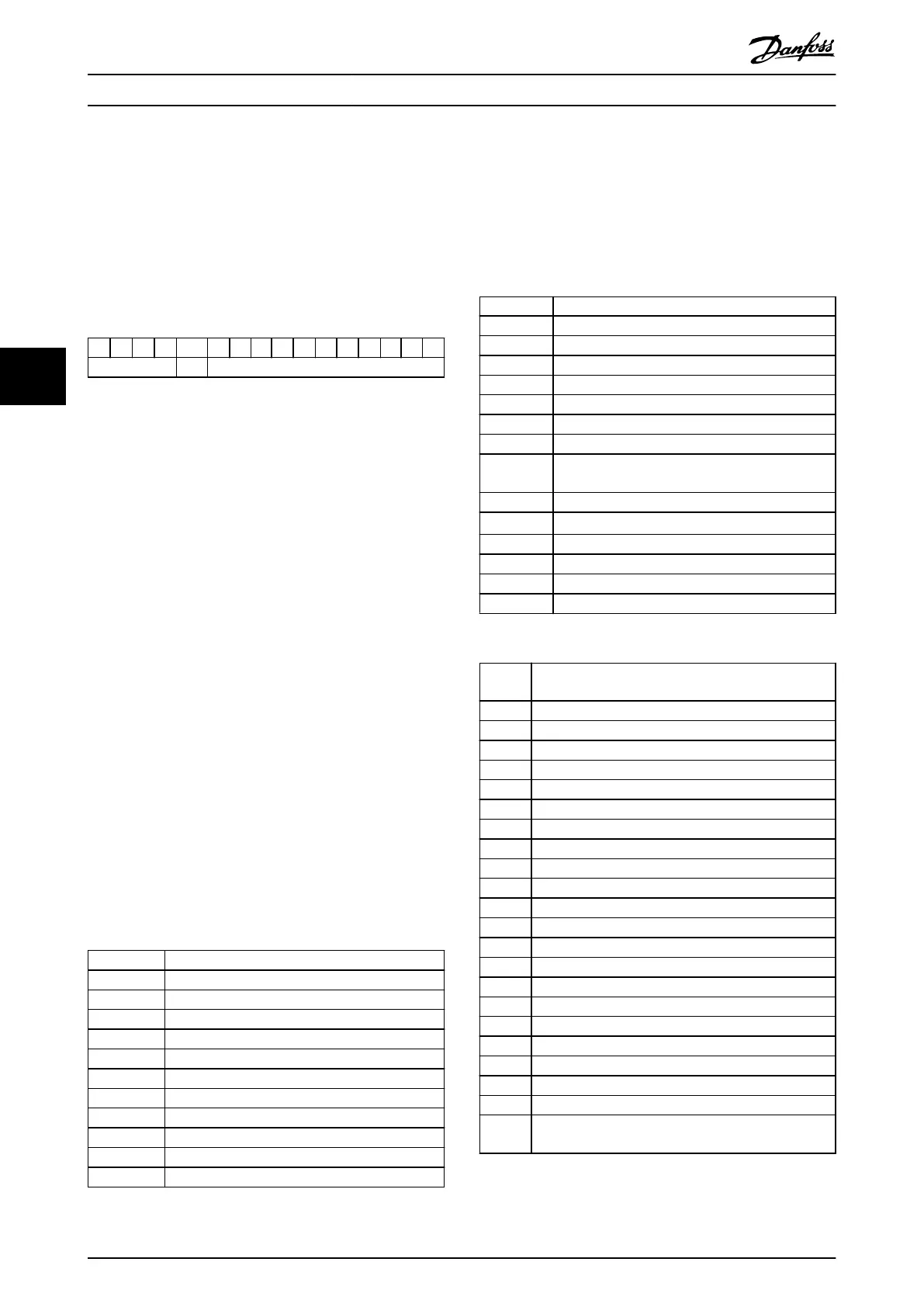

5.3.4 RC Content

Request

The content of the RC portion of the PCA word for a

request is listed in Table 5.15.

Request Function

0 No request.

1 Request parameter value.

2 Change parameter value (word).

3 Change parameter value (long word).

4 Request description element.

5 Change description element.

6 Request parameter value (array).

7 Change parameter value (array word).

8 Change parameter value (array long word).

9 Request number of array elements.

10–15 Not used.

Table 5.15 Request

Response

When the slave rejects a request from the master, the RC

word in the PPO-read indicates the rejection by assuming

the value 7. Bytes 7 and 8 in the PVA element carry the

fault number.

The content of the RC portion of the PCA word for a

response is listed in Table 5.16.

Response Function

0 No response.

1 Transfer parameter value (word).

2 Transfer parameter value (long word).

3 Transfer description element.

4 Transfer parameter value (array word).

5 Transfer parameter value (array long word).

6 Transfer number of array elements.

7 Request rejected (including fault number, see

Table 5.17).

8 Not serviceable by PCV interface.

9 Not used.

10 Not used.

11 Not used.

12 Not used.

13–15 Not used.

Table 5.16 Response

Fault

number

Interpretation

0 Illegal PNU.

1 Parameter value cannot be changed.

2 Upper or lower limit exceeded.

3 Subindex corrupted.

4 No array.

5 Data type false.

6 Cannot be set by user (reset only).

7 Description element cannot be changed.

8 IR required PPO-write not available.

9 Description data not available.

10 Access group.

11 No parameter write access.

12 Key word missing.

13 Text in cyclic transmission not readable.

14 Name in cyclic transmission not readable.

15 Text array not available.

16 PPO-write missing.

17 Request temporarily rejected.

18 Other fault.

19 Data in cyclic transmission not readable.

130 There is no bus access to the parameter called.

131 Data change is not possible because factory set-up is

selected.

Table 5.17 Fault Numbers

Parameter Access

VLT

®

PROFIBUS DP MCA 101

32 Danfoss A/S © 01/2016 All rights reserved. MG37G202

55

Loading...

Loading...