Chapter 12 Descriptions of Parameter SettingsC2000 Plus

12.1-10-4

10-04

Mechanical Gear at Load Side A1

10-05

Mechanical Gear at Motor Side B1

10-06

Mechanical Gear at Load Side A2

10-07

Mechanical Gear at Motor Side B2

Default: 100

Settings 1–65535

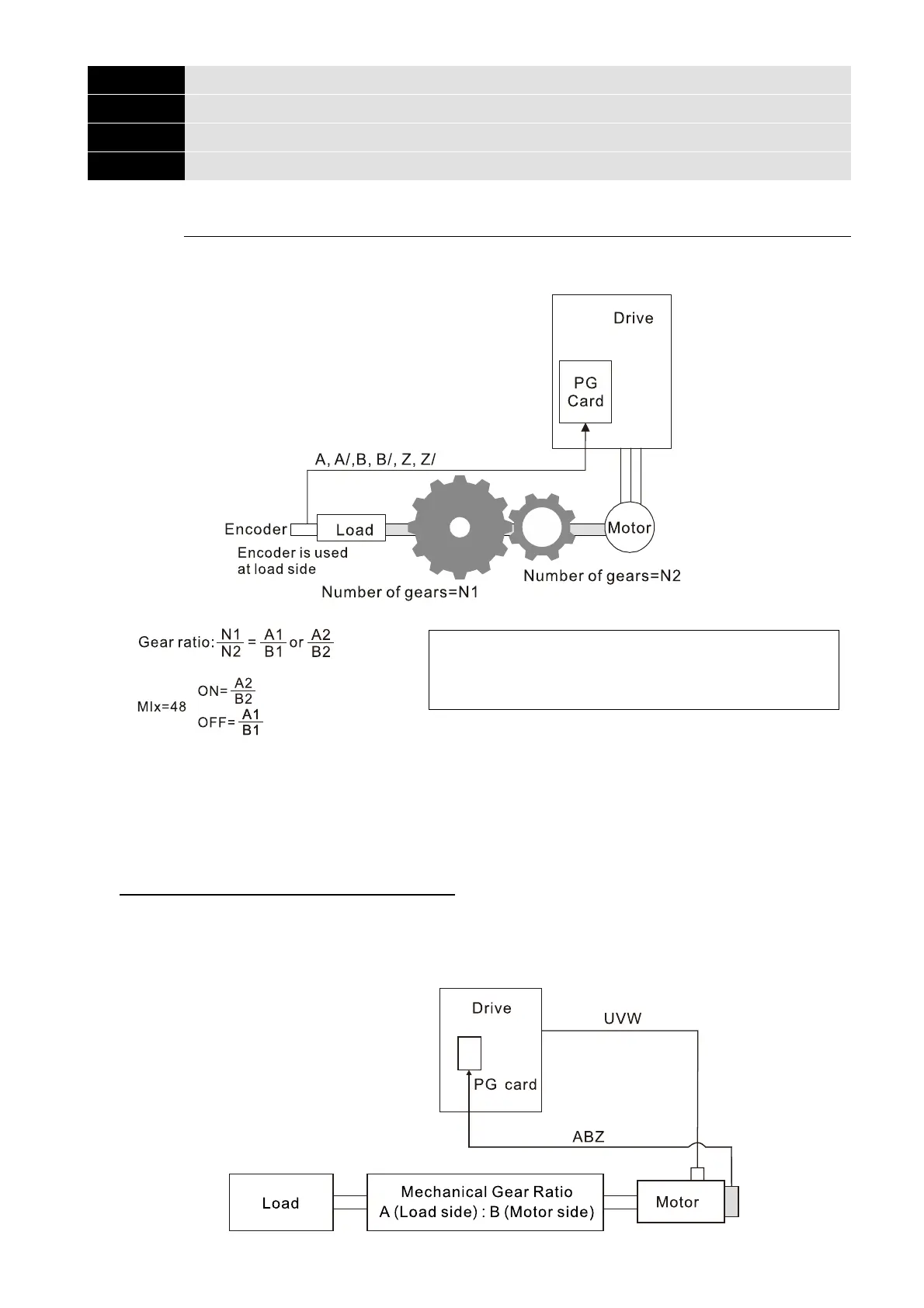

Use Pr.10-04–Pr.10-07 with the multi-function input terminal setting 48 to switch to Pr.10-04–

Pr.10-05 or Pr.10-06–Pr.10-07, as shown in the diagram below.

A1 = Mechanical Gear A1 at Load Side (Pr.10-04)

B1 = Mechanical Gear B1 at Motor Side (Pr.10-05)

A2 = Mechanical Gear A2 at Load Side (Pr.10-06)

B2 = Mechanical Gear B2 at Motor Side (Pr.10-07)

When using the single-point positioning function, consider the mechanical gear ratio and encoder

installation positions (use semi-closed loop control method when the encoder is installed at the

motor side or load side; use fully-closed loop control method when the encoder is installed at the

motor side and the Z-phase signal comes from the load side)

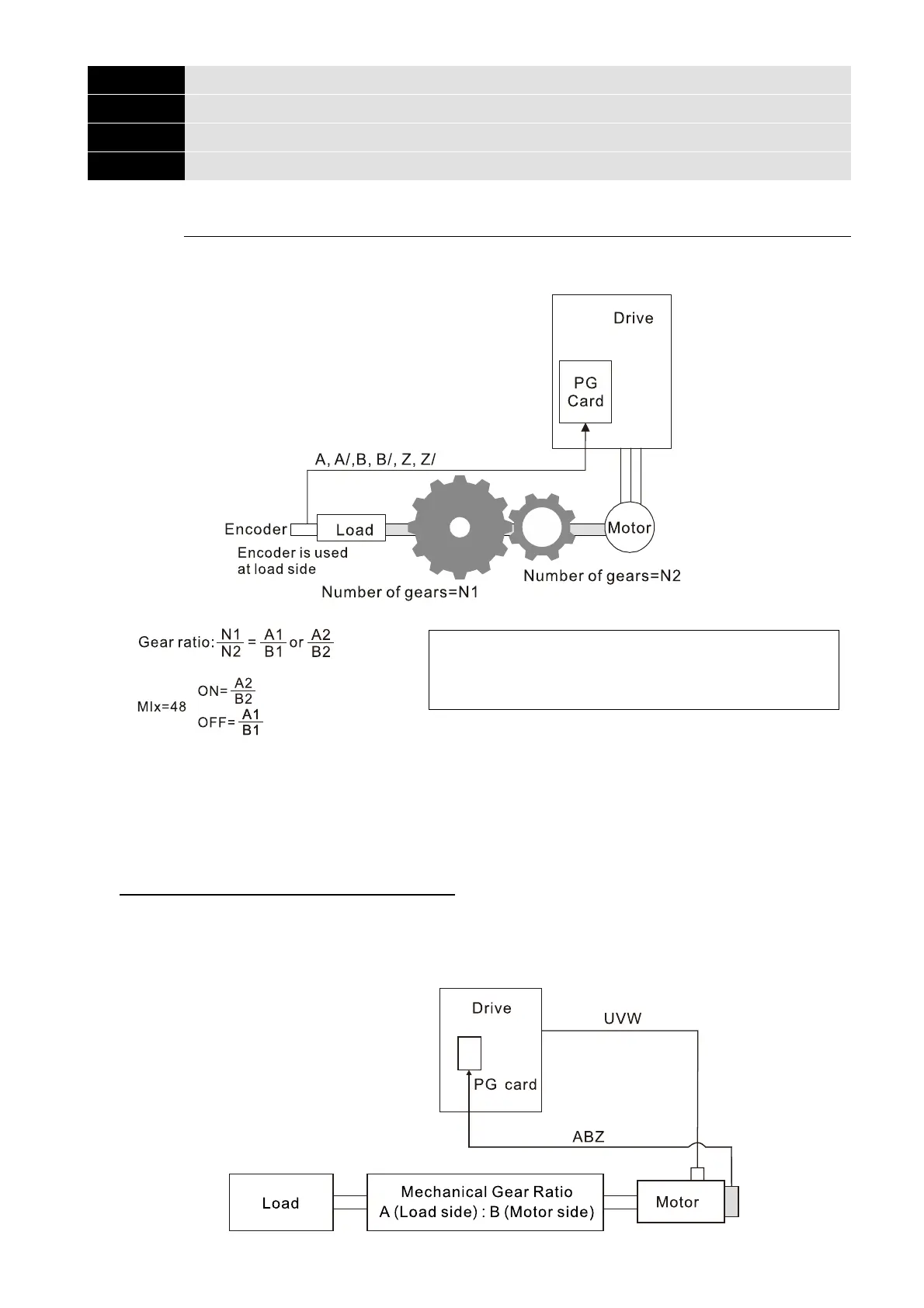

1. Semi-closed loop control method: Type A (Encoder is installed at the motor side)

Since the encoder is installed at the motor side, the drive can only realize the motor placement,

not the actual load placement. In this case, motor placement is regarded as load placement. Thus,

the mechanical gear ratio is 1:1

Loading...

Loading...