D439E Service Manual 4. Fuel system

146

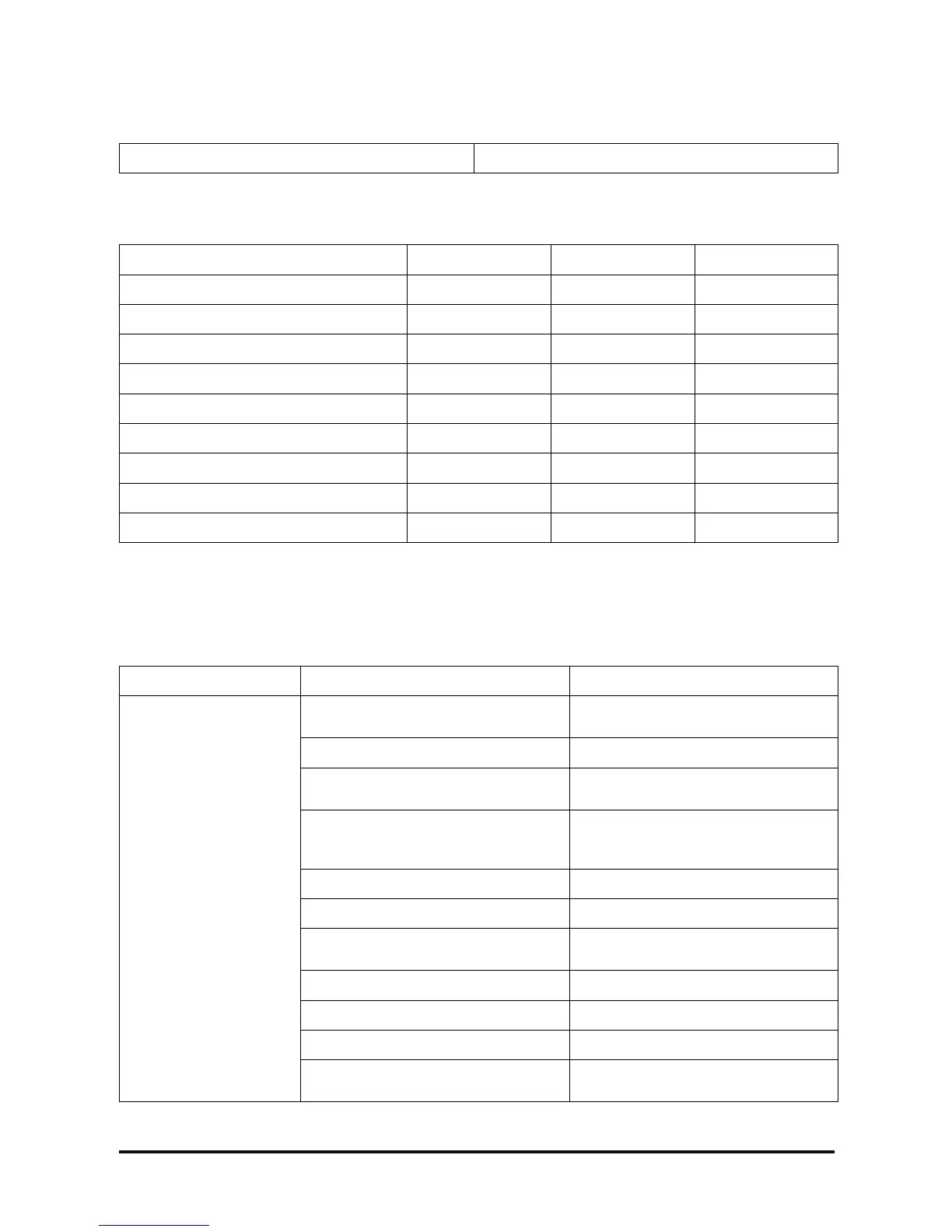

Sealant

Engine Coolant Temperature Sensor Three Bond 2310 or equivalent

Tightening Torque

Items N.m Kgf.m Ib.ft

Commeom rail installation 21.6~32.4 2.2~2.3 15.9~23.9

Engine Coolant Temperature sensor 29.4~39.2 3.0~4.0 21.6~28.9

Pipe (rall-injector 1/2/3/4) 39.2~49 4.0~5.0 29~36.2

Injector clamping bolt 30.4~34.3 3.1~3.5 22.4~25.3

Supply pump fixing bolt 18.6~27.5 1.9~2.8 13.7~20.3

TDC-bolt 7.9~11.8 0.8~1.2 5.8~8.7

CKP-bolt 7.9~11.8 0.8~1.2 7.9~11.8

Pipe (high pressure pump - rail) 39.2~49 4.0~5.0 29~36.2

Supply pump nut 58.8~68.7 6.0~7.0 43.4~50.6

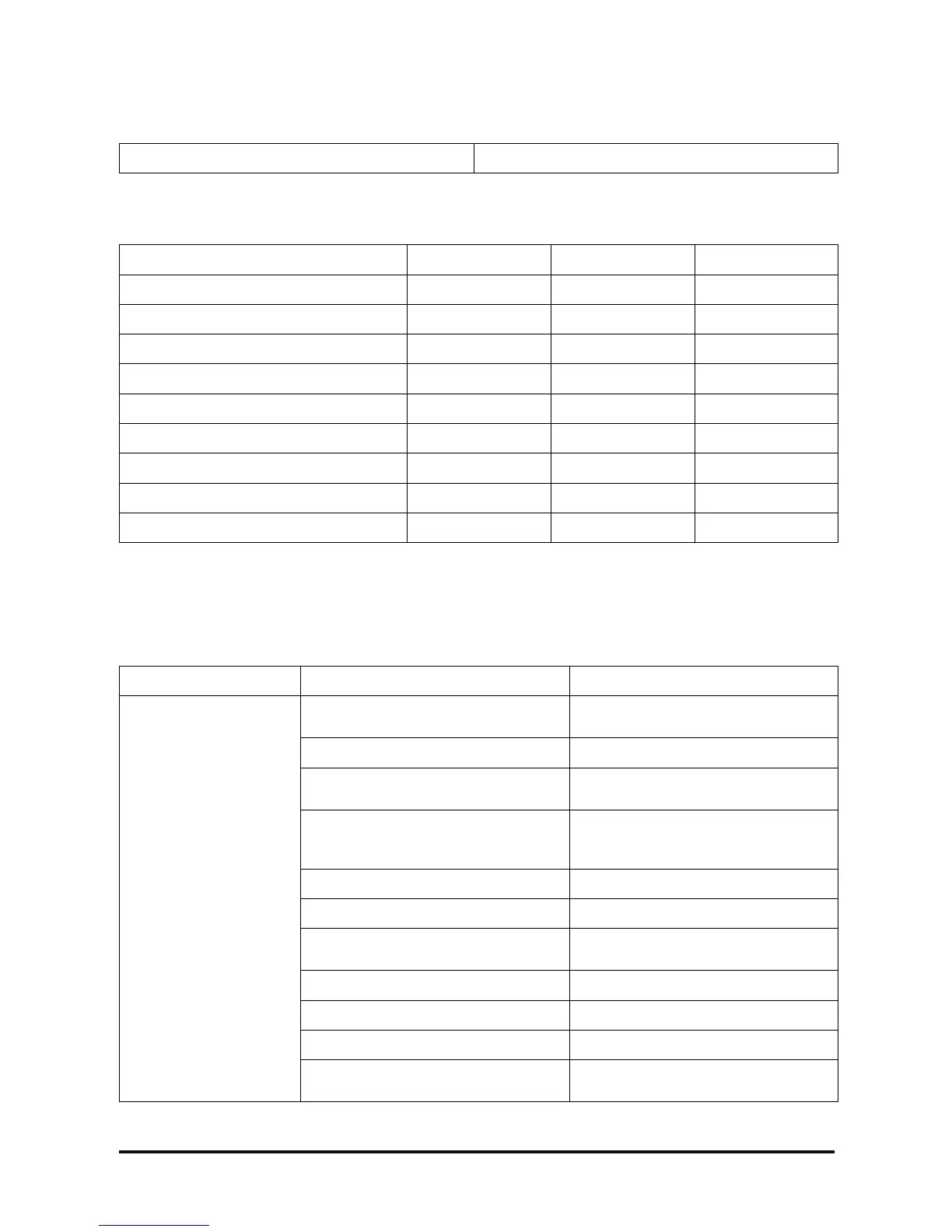

Troubleshooting

Fuel Injection System

Troubles Possible causes Corrective actions

Poor tightening of supply pump nut.

Remove the supply pump and check

nut tightening.

Defective SCV of supply pump Replace

Low cranking speed

Repair the starter or charge or replace

battery.

Low voltage to glow plug system

If the test light turns on indicating low

voltage when it turns “ON”, check

relay and wiring

Defective glow plug Replace the glow plug

Air in the fuel system Air bleeding of fuel system

Injection pipe is connected

incompletely.

Connect the pipe correctly

Improper injection timing Check ECU

Poor injection Check, replace injector

Mechanical defect of engine Compression test, repair engine

Engine does not crank.

Simultaneous failures of TDC sensor

and CKP sensor

Check and tighten correctly Replace

Loading...

Loading...