D439E Service Manual 2. Engine Mechanical System (D439E)

32

Adjustment

Compression Pressure

1. Before performing on-vehicle inspection, check to

see whether engine oil, starter motor and battery

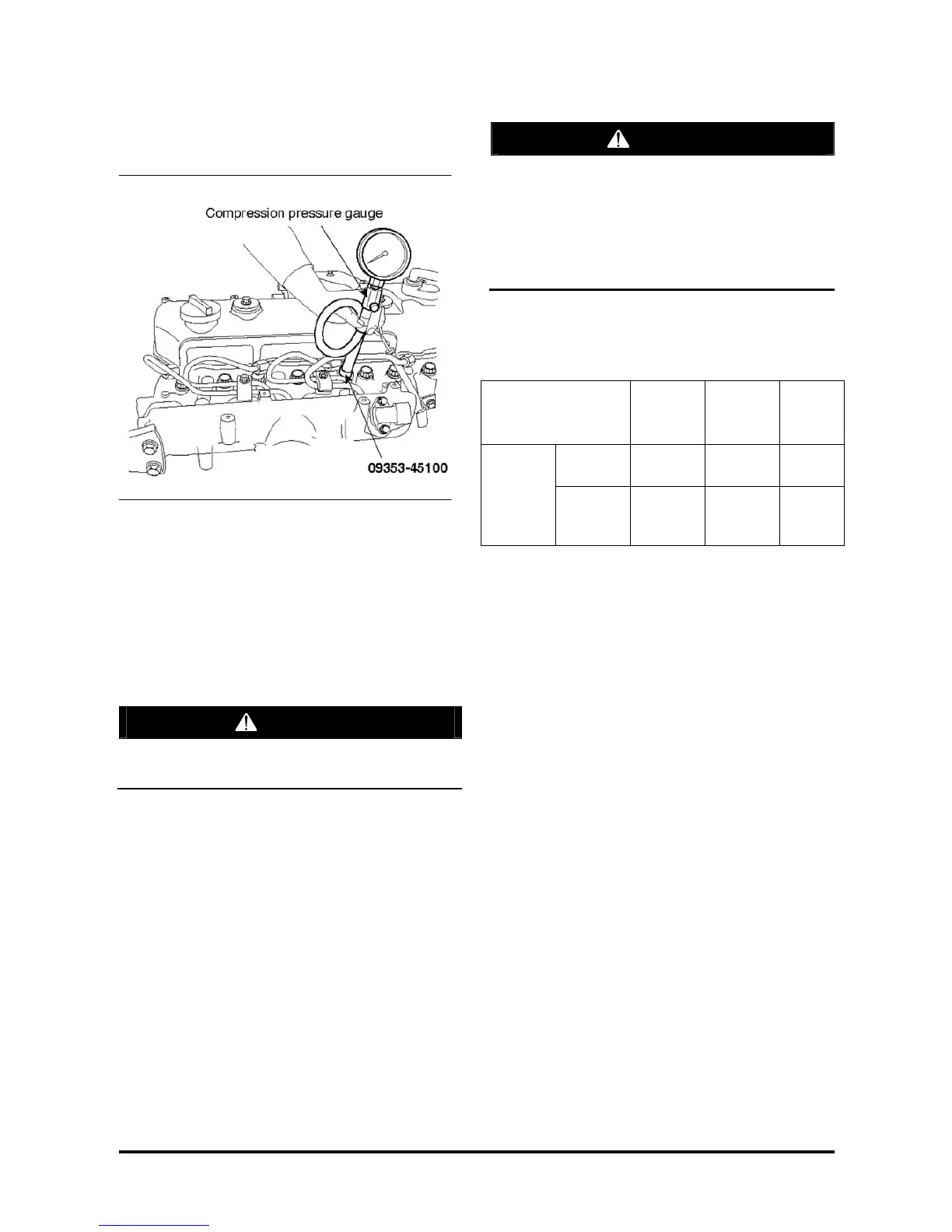

are in normal condition.

2. Start the engine and warm up until the coolant

temperature reaches 80~90℃

3. Stop the engine and remove the ECM fuse.

4. Remove all injectors from cylinder head.

CAUTION

Be careful that foreign materials do not intrude

through the injector installation hole.

5. Crank the engine to remove the foreign materials

from cylinders.

6. Install compression gauge adaptor (09353-45100)

together with gasket and then, connect the

compression gauge.

7. Crank the engine and measure the compression

pressure.

CAUTION

a. Take care that fuel is not injected.

b. Since compression pressure varies

depending on the engine speed, be careful in

measuring.

c. Since worn amounts of each cylinder are

different, measure the pressure at all cylinders.

8. Measure the compression pressure of all

cylinders to see if all compression pressures are

within the limit.

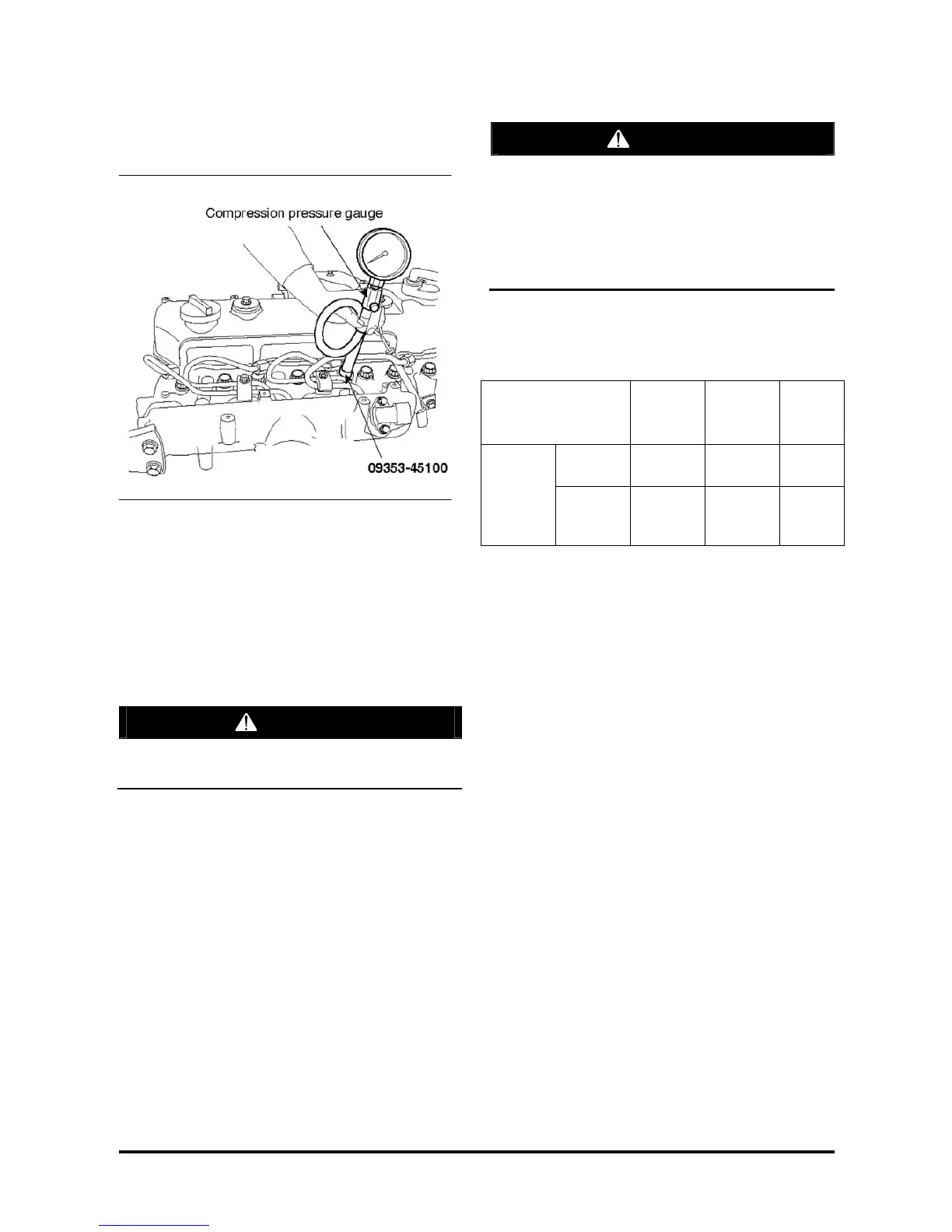

Items

Standar

d

Limit

Corre

ctive

action

Each

cylinder

26kg/cm

2

20kg/cm

2

Check

Compress

ion

pressure

(200rpm)

Difference

between

cylinders

- 4kg/cm

2

Check

9. If the compression pressure difference of any

cylinder exceeds the limit, fill some engine oil

through injector hole and measure the

compression pressure of the cylinder again.

1) If the compression pressure increases, it

indicates that the piston, piston, piston ring or

cylinder wall is worn or damaged.

2) If the compression pressure does not increase,

it indicates that valve is stuck, valve contact is

poor or pressure is leaking through the cylinder

head gasket.

Loading...

Loading...