D439E Service Manual 2. Engine Mechanical System (D439E)

75

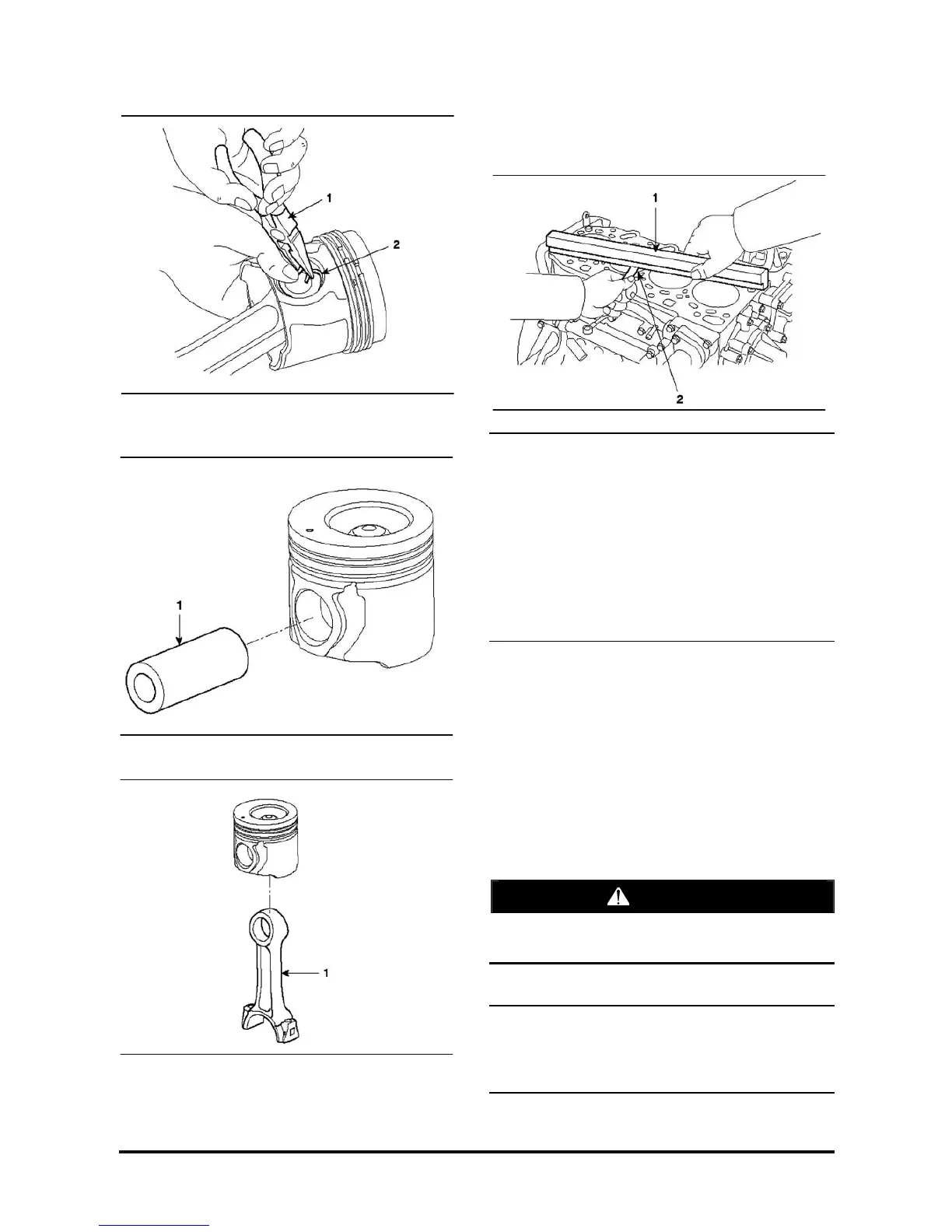

2. Remove the piston pin snap ring (2) using the

snap ring pliers (1).

3. Remove the piston pin (1) from the piston.

4. Remove the connecting rod (1) from the piston.

Inspection

Cylinder Block

NOTE

a. Before repairing, clean each part to remove dust,

oil, carbon and fur.

b. Before cleaning the cylinder block, check water

leakage or damages.

c. Remove the adhesives at each oil hole using air

brush and check whether any hole is clogged.

1. In addition to the visual check about scratch, rust

and corrosion, inspect the slight scratches with

precipitant. Repair or replace it if needed.

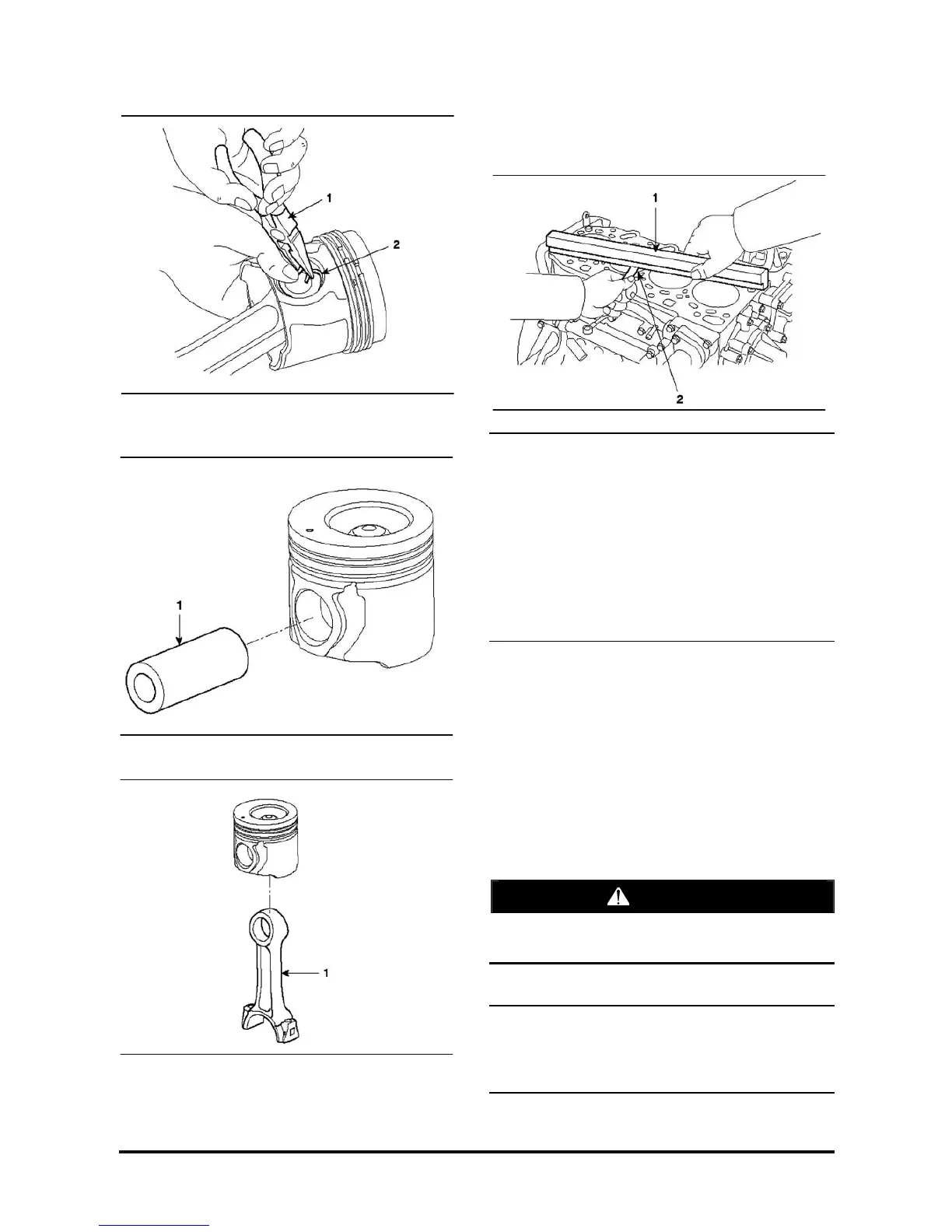

2. Measure the twist of cylinder block using straight

edge (1) and thickness gauge (2). Measure them

by placing the straight edge as shown in the

following figure.

NOTE : When measuring, cylinder upper block

should be free from foreign materials such as gasket

piece.

CAUTION

When grinding the cylinder block, grind it as the

piston protrusion does not exceed the reference.

Flatness figure of cylinder block

Reference : Below 0.07 mm

Limit : 0.2 mm

Loading...

Loading...