49

Level Sensor Leak Troubleshooting & Repair

If a substandard result occurs, then the following procedures need to be

followed to determine where the leak is occurring and how to repair the

Level Sensor Assembly.

1. While the assembly is under pressure (82” – 90” of water (in air)), spray soapy water

or leak detector around barbed fitting, and the joint between the two assembly

halves.

2. If a leak is detected around the barbed fitting, install a new fitting and retest the

assembly.

3. Check for leaks around all joints of the test assembly.

4. Lay the LSA on its side and spray soapy water so that it runs over the column hole in

the bell area to see if it is leaking passed the switches.

5. Check for leaks on the test assembly.

6. If you cannot determine the exact location of the leak, replace the entire assembly.

7. If any of the methods above are unable to eliminate the leak, replace the entire

assembly.

8. Before re-installing the equalizer tube onto the barbed fitting, snip ½” of the tubing off

to ensure a good seal.

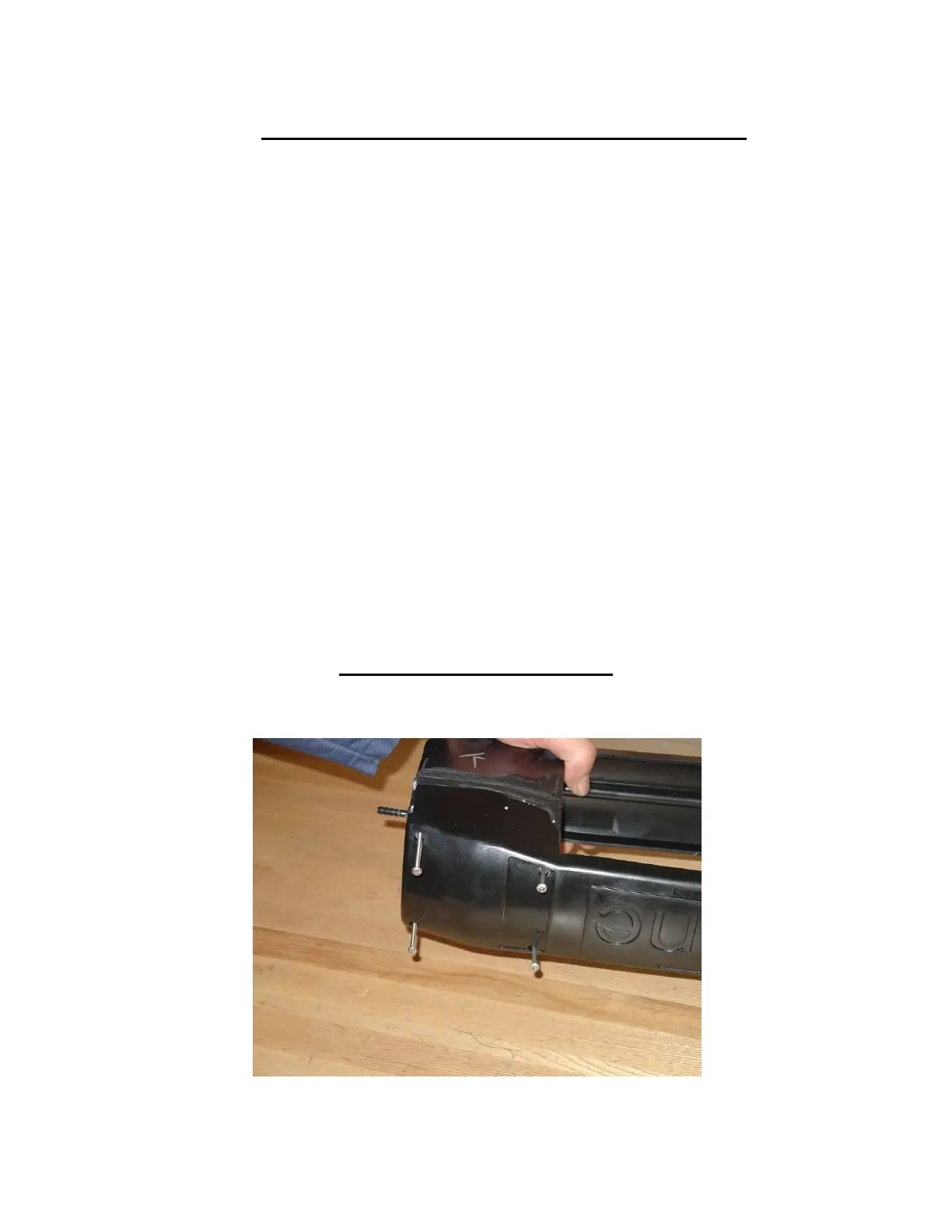

Level Sensor Disassembly

1. Loosen and remove the four Philip head screws that hold the Level Sensor assembly

together.

Figure 9 – 3

Loading...

Loading...