64

Motor Windings Test

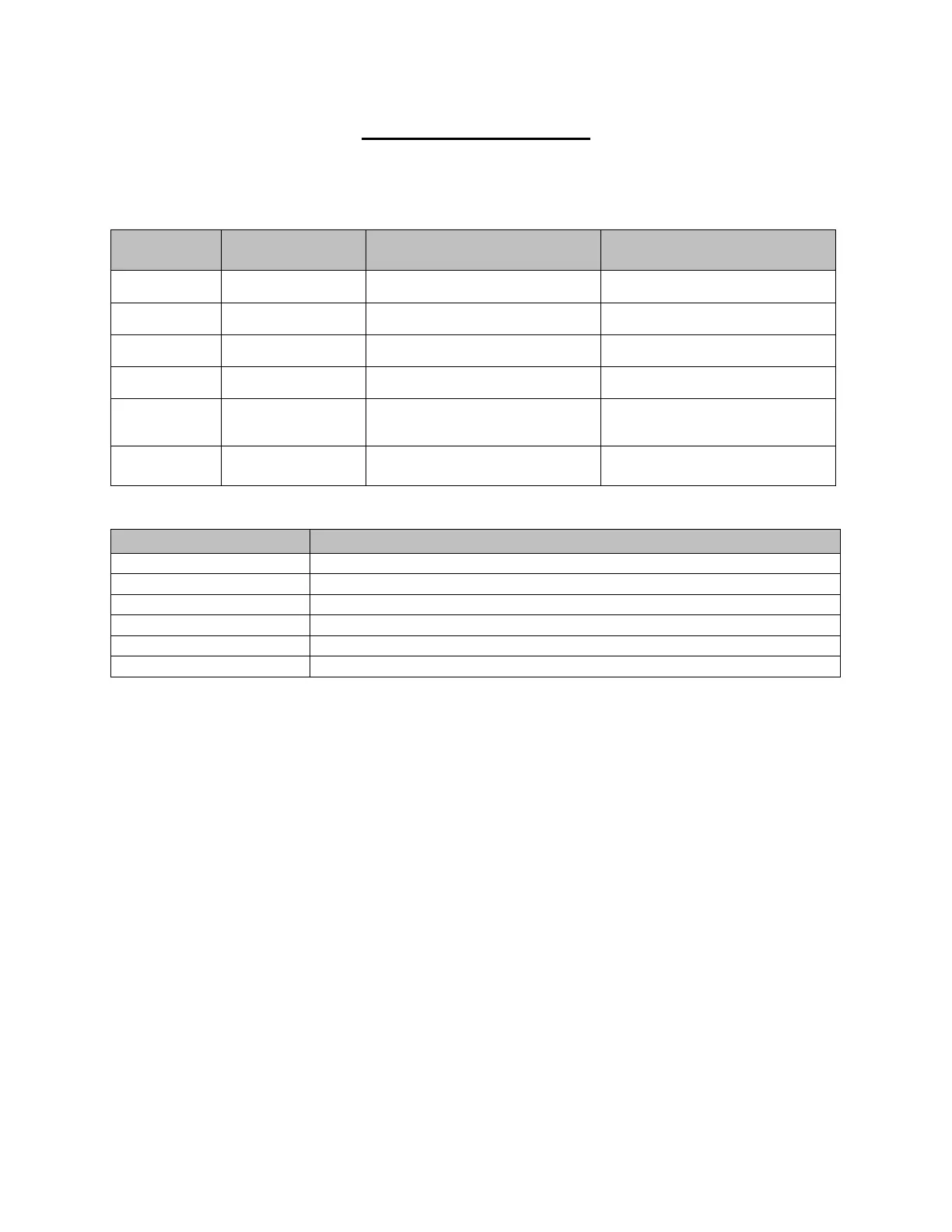

1. Perform motor winding resistance check per chart below to verify motor condition.

Franklin Motor Field Winding Resistance

Any reading; possibly water in

motor. Dry windings and retest

Table 10 – 1

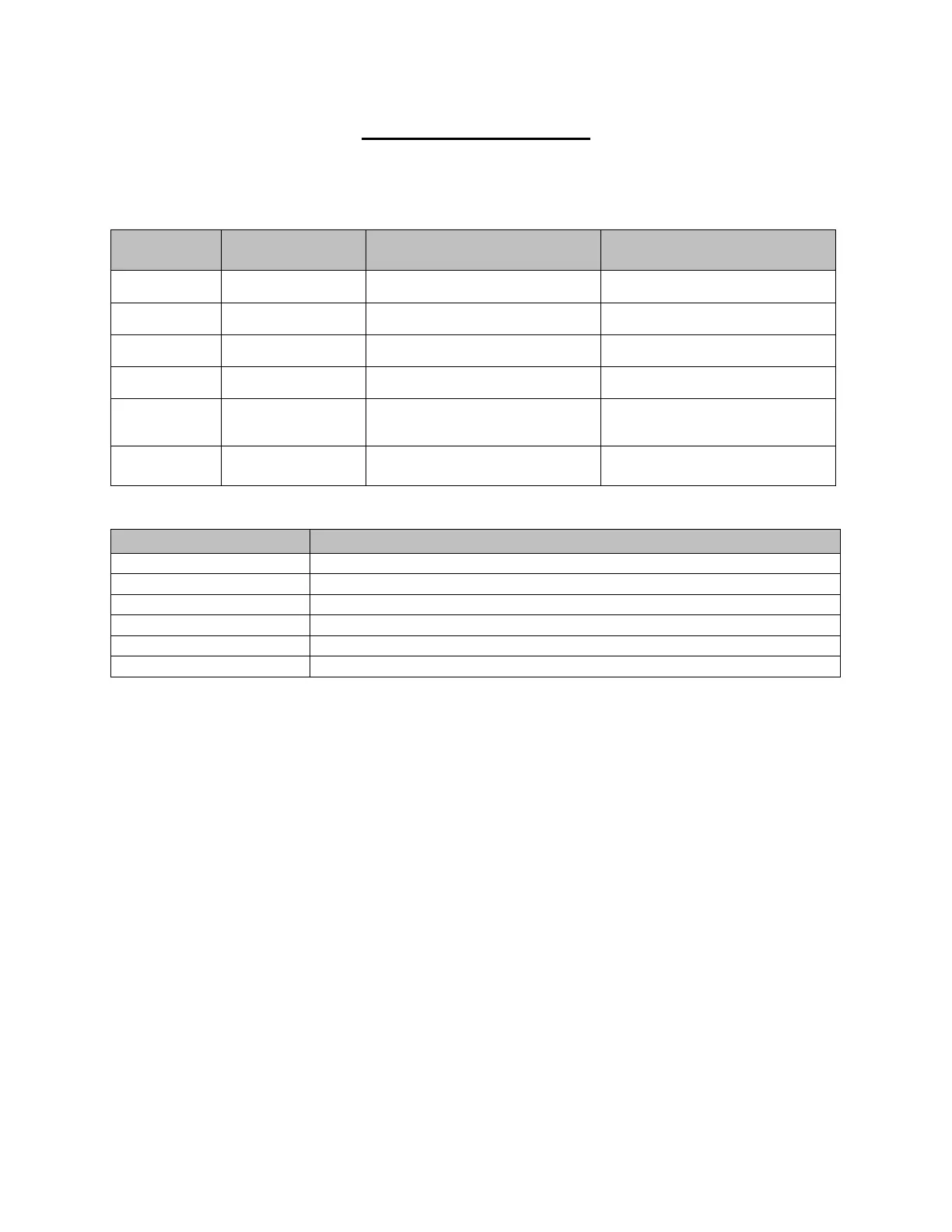

Run/Start windings and internal thermal protector

Jumper lead (120V units Only)

Table 10 – 2

Note: While you have all of the wires disconnected between the Control Bracket, the Power

Cable, and the Transceiver Board, replace the two O-rings on the Motor Casting before you

rewire the Controls. Use Molycote 55 Grease on the Motor Housing and Motor Head O-rings.

Use Silicon Grease on all other O-rings

Control Bracket Installation

1. Plug the yellow wire into terminal 1 on the start switch.

2. Plug the grey wire into terminal 3 on the start switch.

3. Insert the blue wire into 2/T1 on the contactor and tighten.

4. Set the Control Bracket into the control cavity and secure it with the two screws. (Note:

Install the power cable ground wire with the screw on the thermal protector side of the

Control Bracket)

5. Insert the red wire from the Power Cable into 1/L1 on the contactor and tighten.

6. Insert the red wire from the Transceiver Board into 3/L2 on the contactor and tighten.

7. Insert the black wire from the NC-8 crimp wire nut connector and the black wire from the

thermal protector into A1 of the contactor and tighten.

8. Insert the brown wire from the Power Cable and the brown wire from the Transceiver

Board into A2 on the contactor and tighten.

9. Using a butt splice, connect the black motor wire to the black thermal protector wire.

Loading...

Loading...