Communications

Communication ports

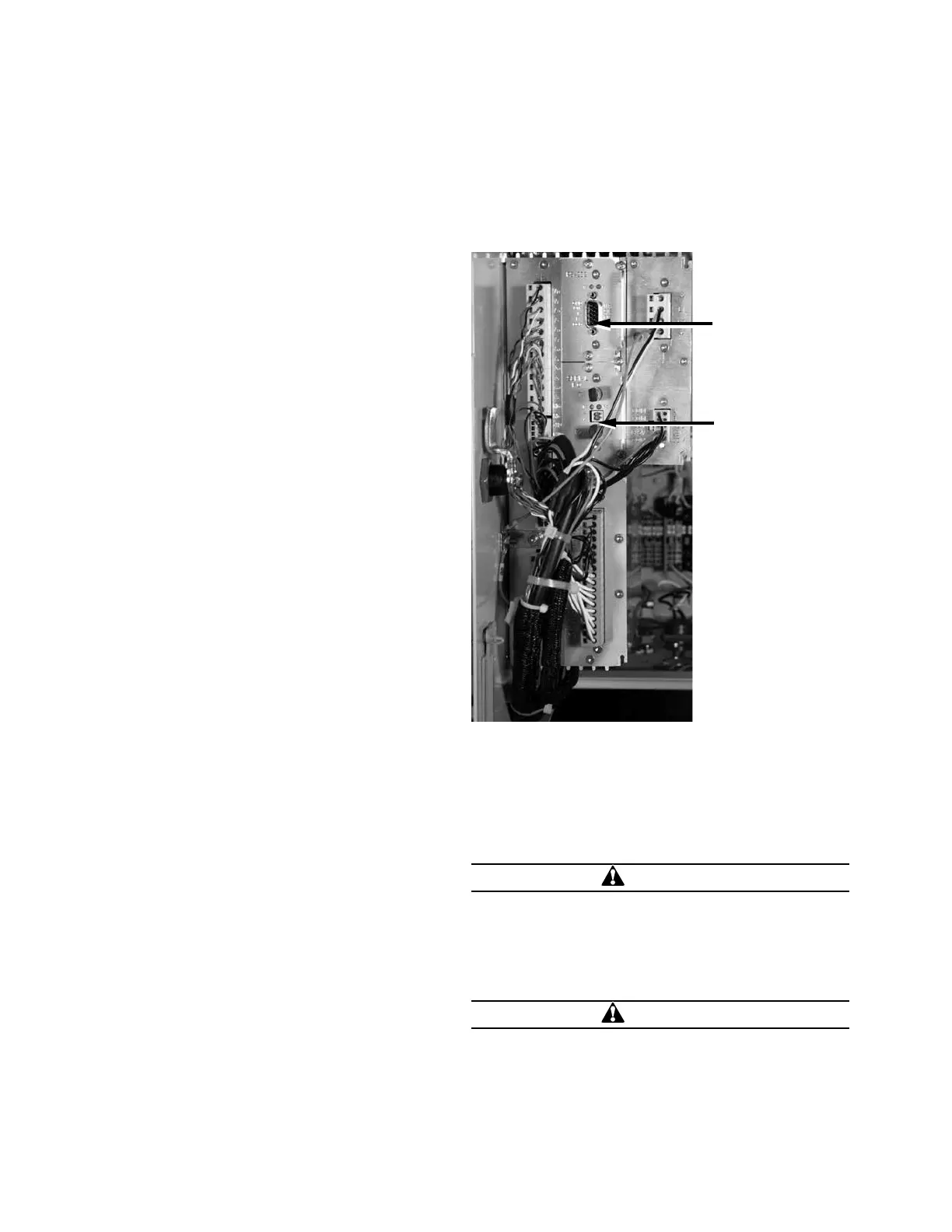

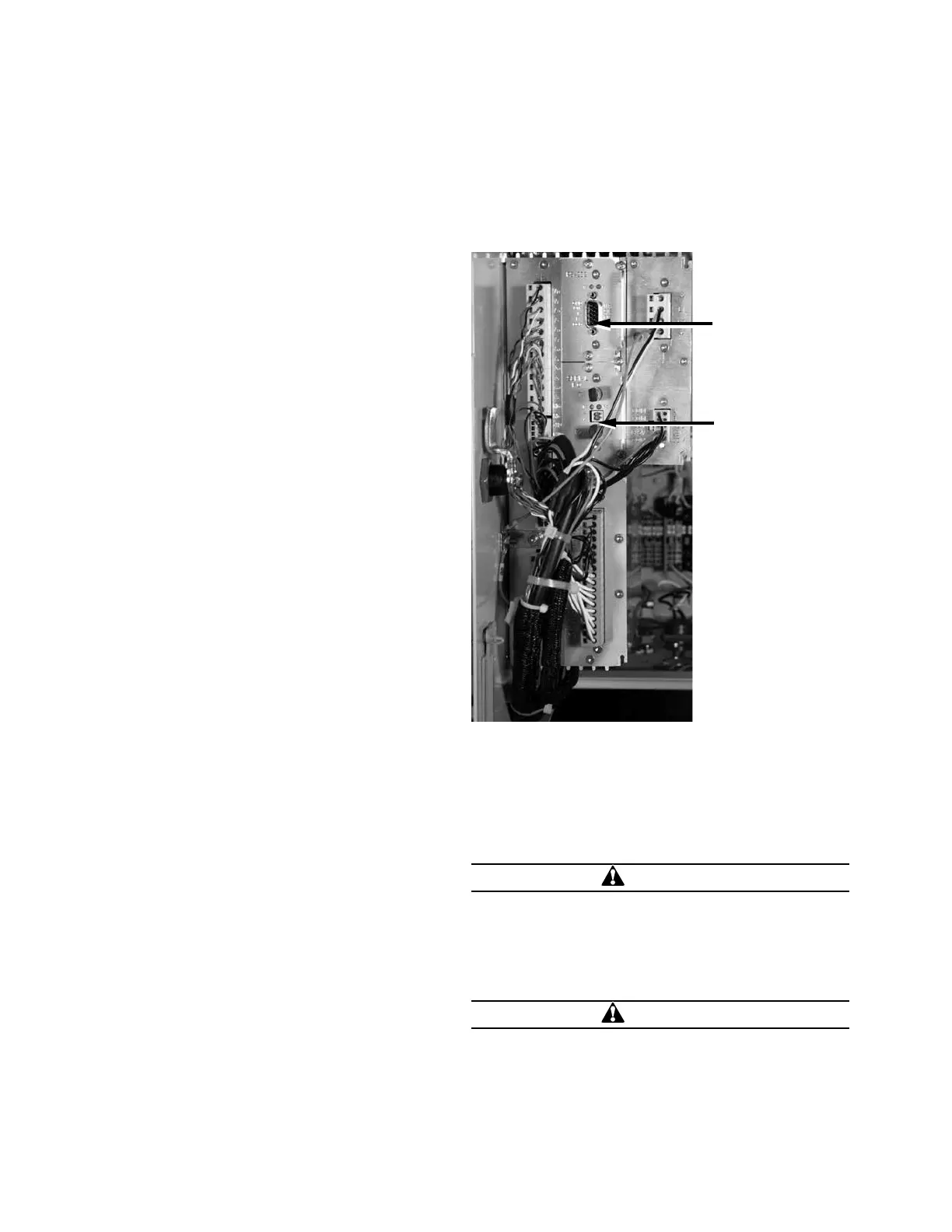

The Form 4D control has a front panel configuration

data port and provisions for two optional side-panel

communication ports (Figure 10).

The front panel configuration data port is described in the

Operating Panel section of this manual.

There are two standard USB ports (one host and one client),

as well as any two of the following: RS-232, RS-485, Serial

fiber, Ethernet wire, Ethernet fiber (MTRJ Multi-mode, SC

Multi-mode, ST Multi-mode, and LC Single-mode).

Communication protocols

Seven native communication protocols are available for the

Form 4D recloser control:

Serial protocols

DNP3

2179

MODBUS

IEC 60870-5-101

Ethernet protocols

DNP3 TCP/IP

MODBUS TCP/IP

IEC 70870-5-104

Any available communication protocol can be selected

and configured by the user with the ProView NXG

applicationsoftware.

DNP3 is factory-defaulted to the communication ports on

the side panel.

Ethernet Communications

ProView NXG over TCP/IP.

DNP3 IP.

IEC60870-5-104.

Ethernet connection allows for network application of the

Form 4D pole-mount control for both DNP3 and ProView

NXG protocols. In addition, the front panel data port can

simultaneously communicate ProView NXG to the PC.

Ethernet configuration is accomplished via ProView NXG

interface software. Refer to S280-104-2 Form 4D Control

Programming Guide for Ethernet Configuration information.

The user can simultaneously communicate to the Form

4D control using both the front panel data port and the

appropriate side panel communication port.

Control information

Control information includes firmware identification by

catalog number and name, date code, and ProView NXG

release number. Control information is available through the

NAMEPLATE DATA menu on the front panel (Figure 4).

Control side panel

The control side panel is easily accessible when the swing-

panel of the control cabinet is opened.

Port 1:

RS-232 Serial

Communications

option

Port 2:

Serial Fiber, ST

Communica-

tions

Figure 10. Form 4D Pole-mount recloser control

communication port identification

Installation procedure

Initial programming prior to installation

CAUTION

Equipment misoperation. Do not connect this control

to an energized recloser until all control settings have

been properly programmed and verified. Refer to the

programming information for this control. Failure to

comply can result in control and recloser misoperation,

equipment damage, and personal injury.

G110.3

CAUTION

Loss of protection. Reconfigure the user settings. When

the CONTROL OK LED is flashing, control protection

is disabled. User protection profile settings must be

reconfigured to enable protection. Loss of protection can

result in personal injury and equipment damage.

T360.1

12 OPERATION INSTRUCTIONS MN280049EN September 2017

Form 4D Microprocessor-based pole-mount recloser control installation and operation instructions

Loading...

Loading...