Type VSA12, VSA16 and VSA20/800 maintenance instructions

6MAINTENANCE INSTRUCTIONS MN280064EN October 2017

1. If the recloser passes the closed contacts tests

(Tests1 and 2) but fails the open-contacts test (Test

3) a deteriorated vacuum in one or more of the

interrupters is most likely the cause. Retest each

vacuum interrupter individually to determine the failed

phase or phases, and replace the interrupter(s). Retest

to confirm the repair.

2. If the recloser fails the closed-contacts tests

(Tests 1and 2) the cause is likely to be a diminished

electrical clearance or a failed insulation. After

correcting the problem, retest to confirm the repair.

Shop maintenance instructions

The operations described in this section should be

performed under the cleanest conditions possible. No

special tools are required for any of the repair procedures.

Bushings

Bushing maintenance generally consists of a thorough

cleaning and a careful examination for chips, cracks or

other physical damage during the periodic maintenance

inspection. Bushing porcelain must be replaced whenever

damage is discovered. The porcelain can be replaced

without removing the bushing assembly from the recloser.

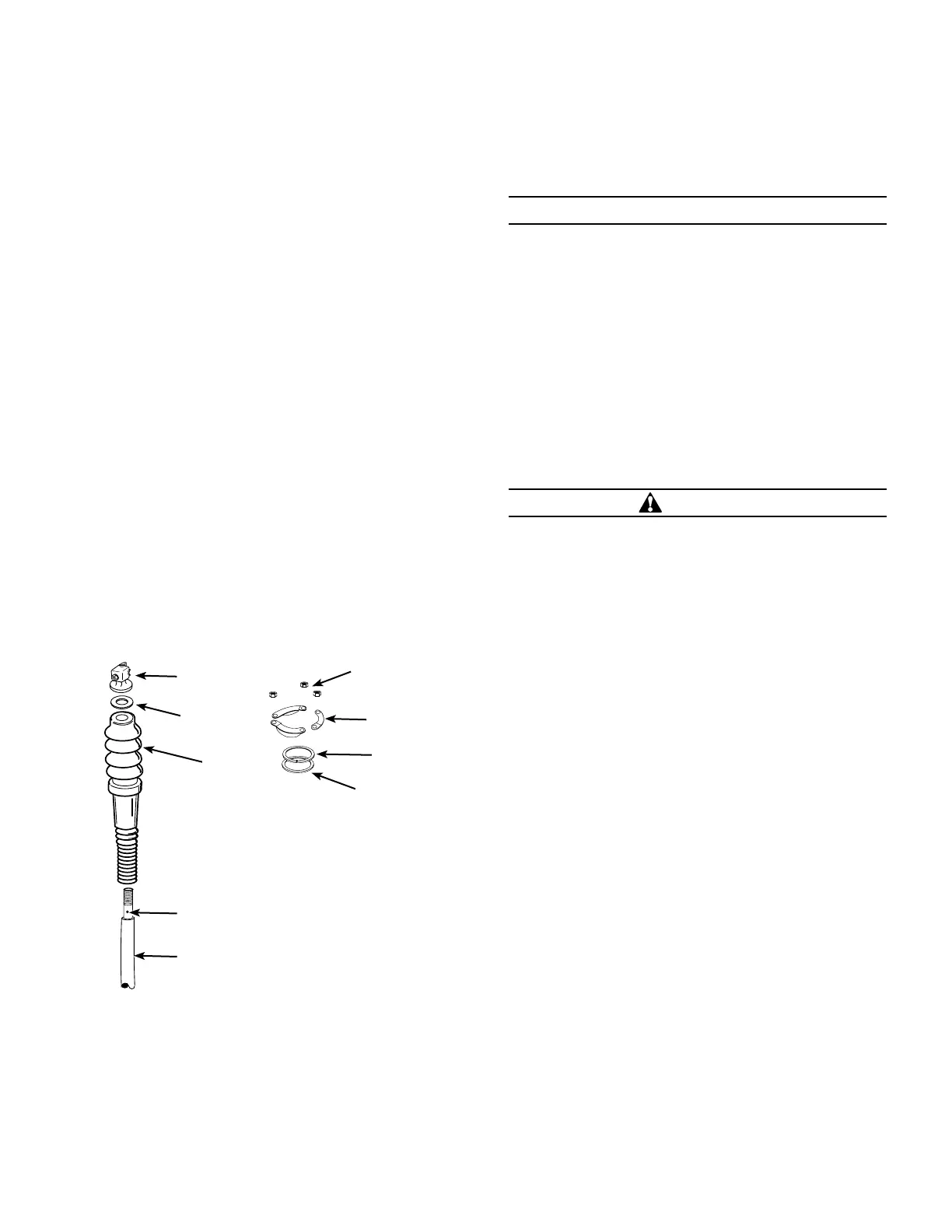

To replace bushing porcelain proceed as follows, refer to

Figure 7:

1. Unscrew the bushing terminal, discard the

terminal gasket.

Bushing

terminal

Terminal

gasket

Bushing

porcelain

Roll pin

Bushing rod

Hex nuts

Bushing

clamps

Split ring

Lower

gasket

Figure 7. Bushing porcelain replacement

2. Remove the three hexnuts and bushing clamps that

secure the bushing to the recloser housing.

3. Remove and discard the lower bushing gasket.

4. Twist off the split aluminum ring from the old bushing

and install on the new bushing porcelain, if it is still in

good condition; replace if damaged.

CAUTION

Bushing damage. The split aluminum ring must be

replaced if damaged. The clamping ring cushions and

distributes the pressure between the bushing flange and

the bushing. If bushing clamps are assembled without a

new clamping ring, the bushing may be damaged when

clamp hardware is tightened.

T234.1

5. Install a new lower bushing gasket and slide the new

bushing porcelain, into the recloser housing, over the

bushing rod. Make sure that the roll pin is seated in the

locking groove in the top of the bushing.

6. Position the clamping ring with the split centered

between two clamp bolts.

7. Install bushing clamp hardware and tighten nuts evenly,

a little at a time, to 6-10 ft-lbs. torque.

CAUTION

Dielectric failure, bushing damage. To prevent gasket

leaks or bushing damage, clamping force must be applied

gradually and equally in rotation to each bolt. If the

clamping force is not evenly applied, seal leakage can

result, compromising the dielectric capabilities of the

recloser and can cause possible personal injury. Unequal

clamping force can cause bushing breakage.

T235.2

8. Apply a very small amount of petroleum jelly to the

knurled inside surface of the bushing terminal.

9. Install a new terminal gasket and the bushing terminal,

tighten to 35 ft-lbs. torque.

Vacuum interrupters

Vacuum interrupters must be replaced when:

They lose their vacuum as evidenced by a failure during

the low-frequency dielectric withstand test across the

open contacts; or

The interrupter contacts have eroded beyond their useful

life as evidenced by the position of the scribe mark on

the moving contact rod.

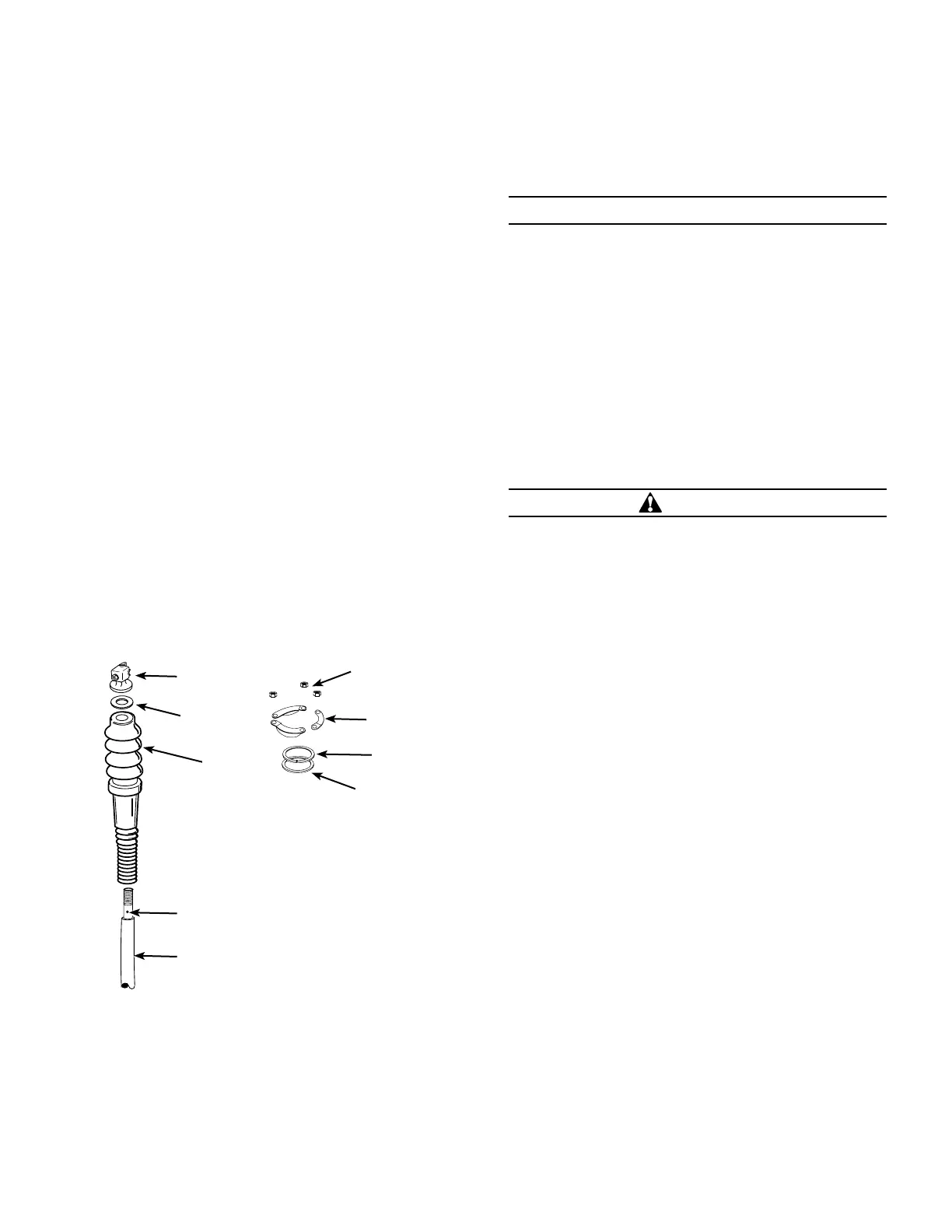

To replace an interrupter refer to Figure 8, and proceed

asfollows:

1. Remove fused pullout switch to de-energize AC power

source to operator mechanism.

2. Make sure recloser contacts are open; manually

operate mechanism until contact position indicator

reads OPEN and closing spring status indicator reads

SPRINGS DISCHARGED.

3. Remove nylon hardware, or wire tie, securing insulating

barrier to stringers, remove insulating barrier.

4. Remove hardware and clamp that secure long bushing

rod to lower interrupter support bracket.

Loading...

Loading...