Type VSA12, VSA16 and VSA20/800 maintenance instructions

11 MAINTENANCE INSTRUCTIONS MN280064EN October 2017

Recloser contacts in

closed position

1

2

A

B

C

MA

MA

MA

K

G

H

J

A

B

C

K

G

H

J

MA

100 AMP AC test

circuit

Test leads connecting

phases in series

Control cable

receptacle sockets

Sensing CT’S

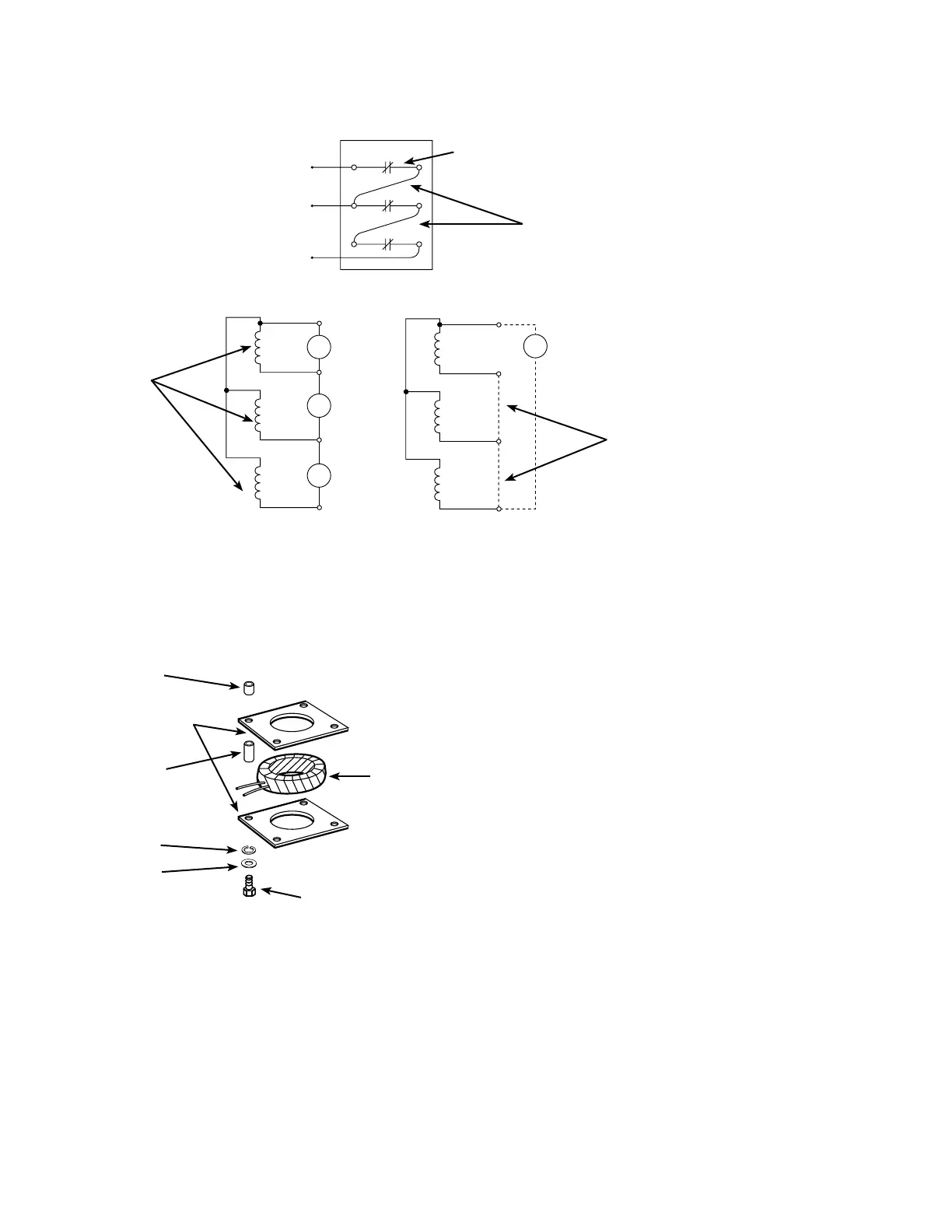

Ratio test circuit (A) Polarity test circuit (B)

Test leads connect

bushing CT

secondaries in parallels

Figure 16. Test circuit for checking bushing current transformers

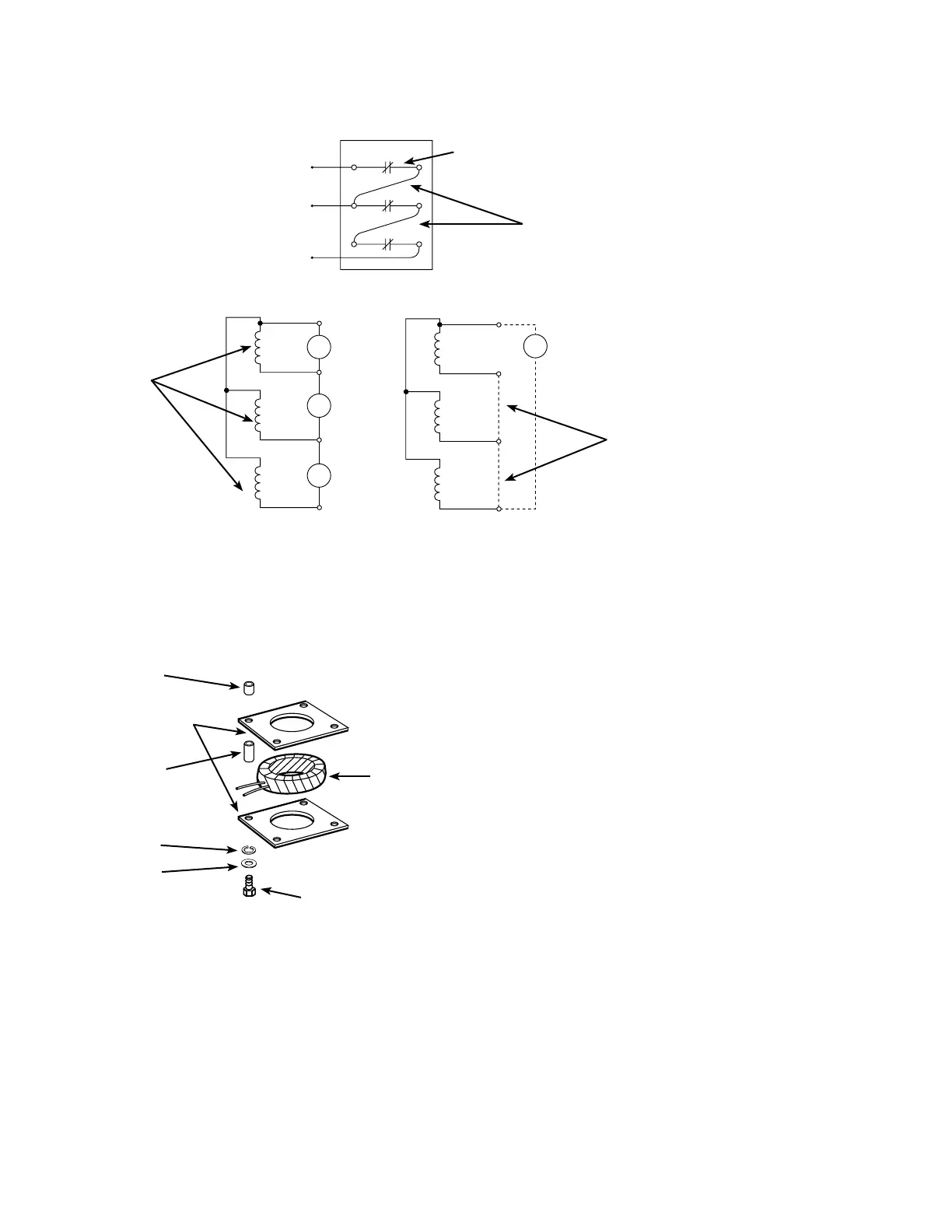

Sensing-current transformer replacement

To replace a damaged current sensing transformer proceed

as follows, refer to Figure 17.

Spacer

Coil retainer plate

Washer

Lockwasher

Sensing CT

Capscrew

Figure 17. Current sensing transformer replacement

1. Remove bushing that passes through the current

transformer that is to be replaced.

2. Label sensing current transformer leads. Use labeling in

accordance with connection diagram. The X1 leads are

white and the X2 leads are black.

3. Cut leads, on transformer side of the original splice, to

disconnect current transformer.

4. Remove capscrews that secure current transformers Remove

and discard damaged sensing CT; retain coil retainer plate.

ote:N Sensing CTs are marked with a black spot to indicate

polarity, when installing the replacement CT orient

the black dot to match the dot on the other CTs that

are already installed.

5. Install replacement CT, secure with hardware removed.

6. Trim CT leads as required. Slide shrink tube over each

lead, splice connection and solder. Slide shrink tube

over splice and apply heat to shrink. When splicing

connections, refer to previous labeling to assure proper

leads are connected before soldering.

7. Install bushing assembly.

8. Perform the ratio and polarity tests after replacement of

any sensing CT to make sure they are properly installed.

Control cable check

With the cable removed at the control, use an ohm meter to

check the continuity of each circuit through the connection

at the operator cabinet up to the control terminal block.

The connector pin sockets and the control terminal block

are lettered correspondingly. Remove and replace each

conductor at the control terminal block while checking.

A zero reading will indicate continuity, an infinite reading

indicates an open circuit. Continuity between terminals and

unlike pin socket indicates a shorted circuit. Replace if cable

is damaged.

Control circuit components

The operating sequence of the various circuit components

is diagrammed in Figure 18. See Figures 19 and 20 for

connection diagrams and wiring tables. A schematic

Loading...

Loading...