Type VSA12, VSA16 and VSA20/800 maintenance instructions

7 MAINTENANCE INSTRUCTIONS MN280064EN October 2017

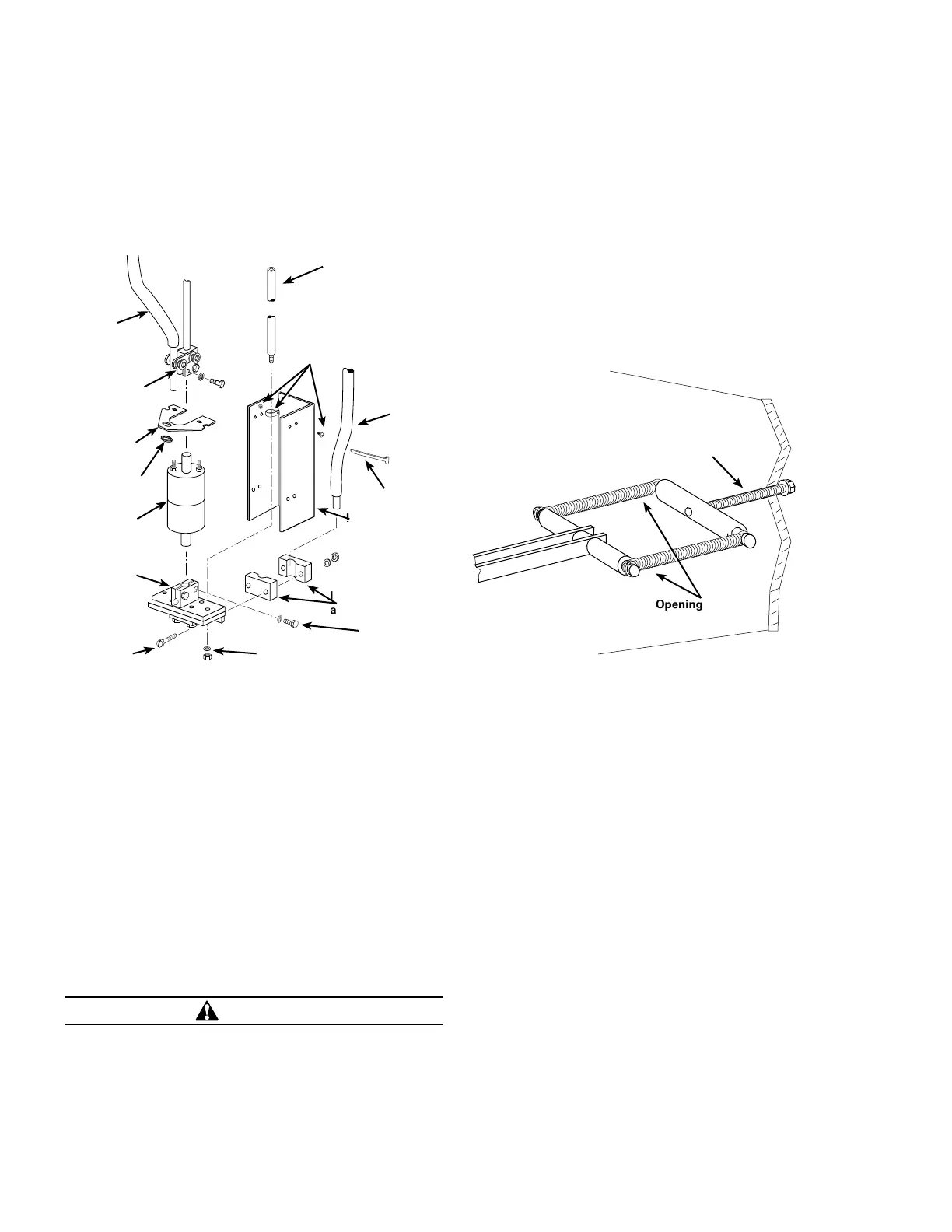

5. Loosen bolts that secure upper interrupter clamp. As

clamp is loosened atmospheric pressure, acting on

the bellows, will cause the contact rod to move down

into interrupter. This action can be verified by observing

the scribe mark on the contact rod. It should move

down, toward contact rod support plate, when clamp

isloosened.

Upper

interrupter

clamp

Insulating

barrier

Nyliner

bushing

Stringer

Nylon hardware

Long

bushing

lead

Wire tie

Insulating

barrier

Bushing

lead clamp

assembly

Clamp

hardware

Stringer

hardware

Figure 8. Vacuum interrupter replacement

ote:N If contact rod does not move, interrupter may have

lost vacuum, or the contact rod may be sticking

within the clamp. Use a screwdriver to gently spread

clamp to free rod.

6. Remove hardware attaching lower current exchange

plate to stringers. Carefully lower plate and vacuum

interrupter assembly from between stringers.

7. Loosen lower current exchange clamp and remove

interrupter. If stationary contact rod sticks within clamp

use a screwdriver to gently spread clamp to free rod.

8. Remove insulating barrier from top of old interrupter

and install on new interrupter.

9. Install stationary contact rod into lower current

exchange plate, do not tighten clamp hardware.

CAUTION

Interrupter damage. When installing the moving contact

rod into the upper clamp avoid twisting or cocking

the rod. Excessive force can damage the bellows,

causing loss of vacuum and irreparable damage to the

interrupter and/or premature interrupter failure.

10. Carefully place interrupter and lower current exchange

assembly into position; situate moving contact rod

within upper clamp as assembly is installed. Install

washers and locknuts to secure lower current exchange

plate to stringers.

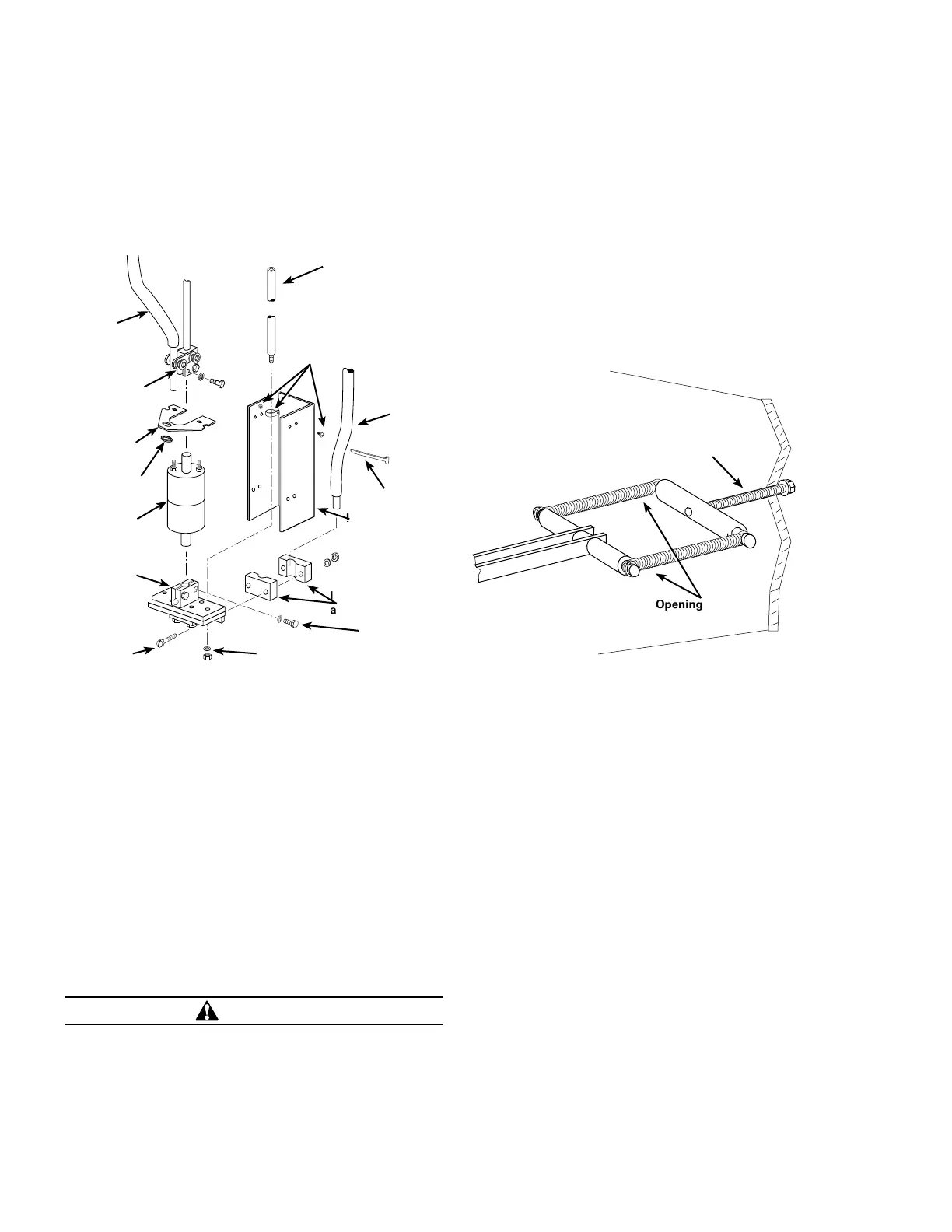

11. Loosen tension bolt to relieve opening spring tension,

Figure 9.

12. Manually close recloser.

13. Tighten top and bottom contact rod clamp hardware to

20-22 ft-lbs torque.

14. Tighten tension bolt to re-apply tension to opening

spring, Figure 9.

Figure 9. Opening spring tension bolt

15. Install clamp and hardware to secure long bushing lead

to lower current exchange assembly and tighten.

16. Manually trip and close recloser several times to check

operation.

1 7. Install insulating barrier and secure with nylon

hardware, or wire ties, as applicable

18. Perform Insulation Level Withstand Test (see page 8).

19. Install fused pullout switch to energize AC power

source to operator mechanism.

Operating mechanism

The spring operated mechanism uses solenoids to release

charged opening and closing springs. The closing springs

are charged by a motor-gear reduction drive. The closing

operation charges the opening springs.

The upper portion of the operating mechanism in the

operator cabinet incorporates the tripping mechanism

which includes the trip solenoid, mechanical linkages and

associated switches. The lower portion of the mechanism

incorporates the closing mechanism which includes the

close solenoid, motor, gear reduction drive, clutch, closing

springs, mechanical linkages and associated switches. The

opening springs and the linkages to operate the interrupters

are located under the head of the recloser.

Tension

bolt

Opening

springs

Loading...

Loading...