Type VSA12, VSA16 and VSA20/800 maintenance instructions

1 MAINTENANCE INSTRUCTIONS MN280064EN October 2017

Introduction

Service Information MN280064EN covers the maintenance

instructions for the type VSA electronically controlled, three-

phase, vacuum recloser. The manual includes a general

description of the recloser and its operation and instructions

for periodic inspection, testing and shop repairs. Keyed

service parts exploded-view drawings of the unit, along with

ordering information are included at the back of the manual.

Description and operation

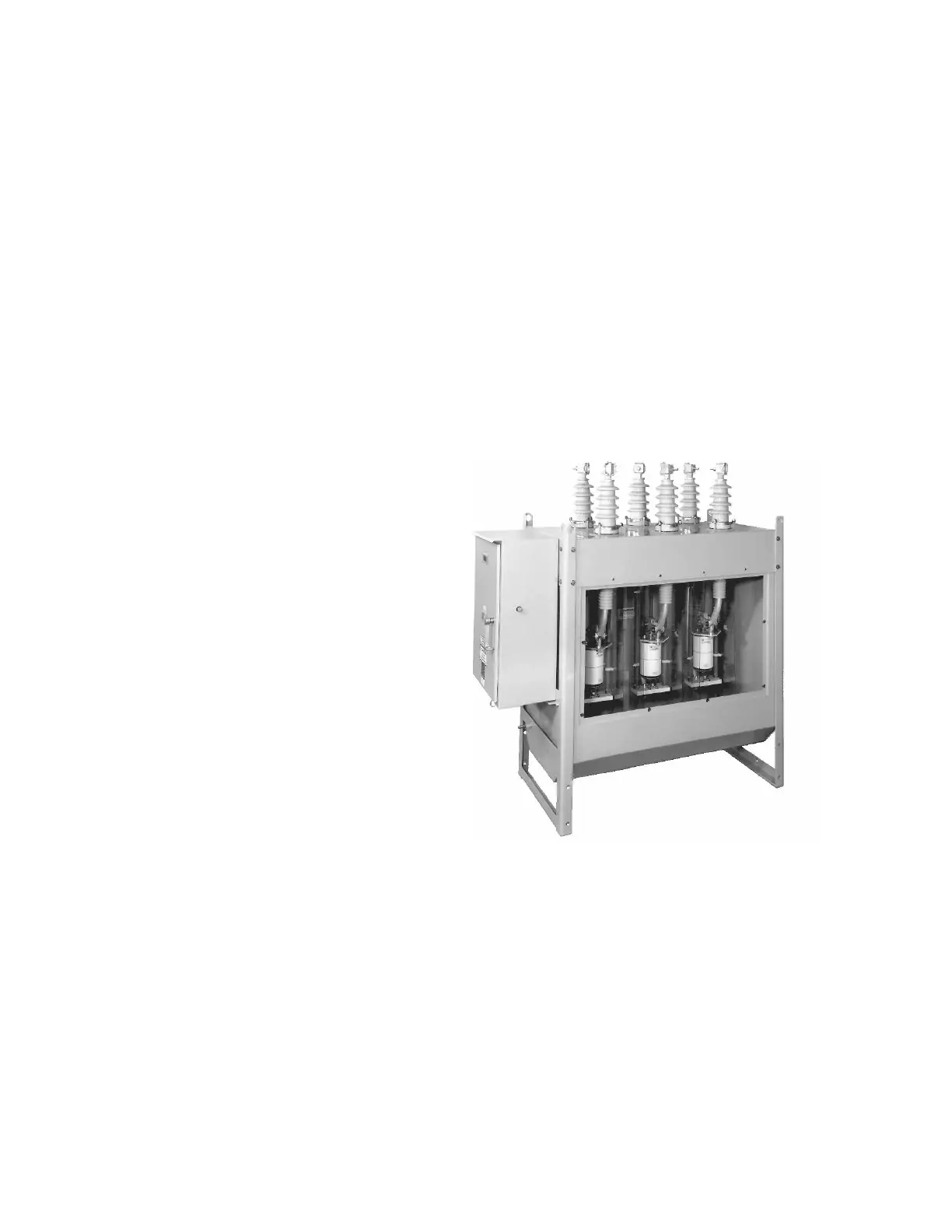

The VSA12, VSA16 and VSA20/800 three-phase reclosers

feature vacuum interruption and air insulation. Current

interruption takes place in the rugged vacuum interrupter

assemblies which are suspended from the recloser cover

by insulating supports, as shown in Figure 1. The moving

contacts, located in each interrupter assembly, driven by the

recloser operating mechanism, close or open the circuit.

Interruption takes place within two and one-half cycles,

while utilizing a contact stroke of one-half inch.

Recloser tripping and closing are initiated by signals from

the recloser control unit. When current in excess of the

programmed minimum trip level is detected, on any phase

or phases, the recloser control initiates a trip signal which

energizes a solenoid in the operating mechanism of the

recloser. When actuated, this solenoid trips the opening

springs, which opens the interrupter contacts.

Closing springs provide the force required to close the

vacuum interrupters, as well as the force required to charge

the opening springs. A 240 Vac motor charges the closing

springs through a multi-stage gear drive. When 240 Vac is

present, the motor is automatically operated to keep the

closing springs in a charged state. To close the recloser the

control initiates a signal which energizes a solenoid in the

recloser operating mechanism. Once actuated the solenoid

releases the closing springs, which close the vacuum

interrupters and charge the opening springs. Therefore a

sequence of Open-Close-Open is available after loss of 240

Vdc power.

An external 240 Vac source is required to operate the drive

motor. A battery, in the electronic control, supplies the 24

Vdc tripping and closing power.

Recloser tripping employs stored spring energy. The stored

spring energy is released, to open the recloser, when the

trip solenoid is actuated by the 24 Vdc trip signal. The 24

Vdc trip signal is originated at the recloser control. The 240

Vac supply is not required to trip the recloser.

A totally manual closing operation can be accomplished

even during loss of motor power and with the closing

springs discharged. A hand crank can be applied to the

motor to charge the closing springs. Once charged, the

closing springs can be released either from inside or from

below the operator mechanism cabinet. As with electrical

operations, the opening springs are charged by release of

the closing springs, so even a manually closed unit has

energy stored for a trip operation.

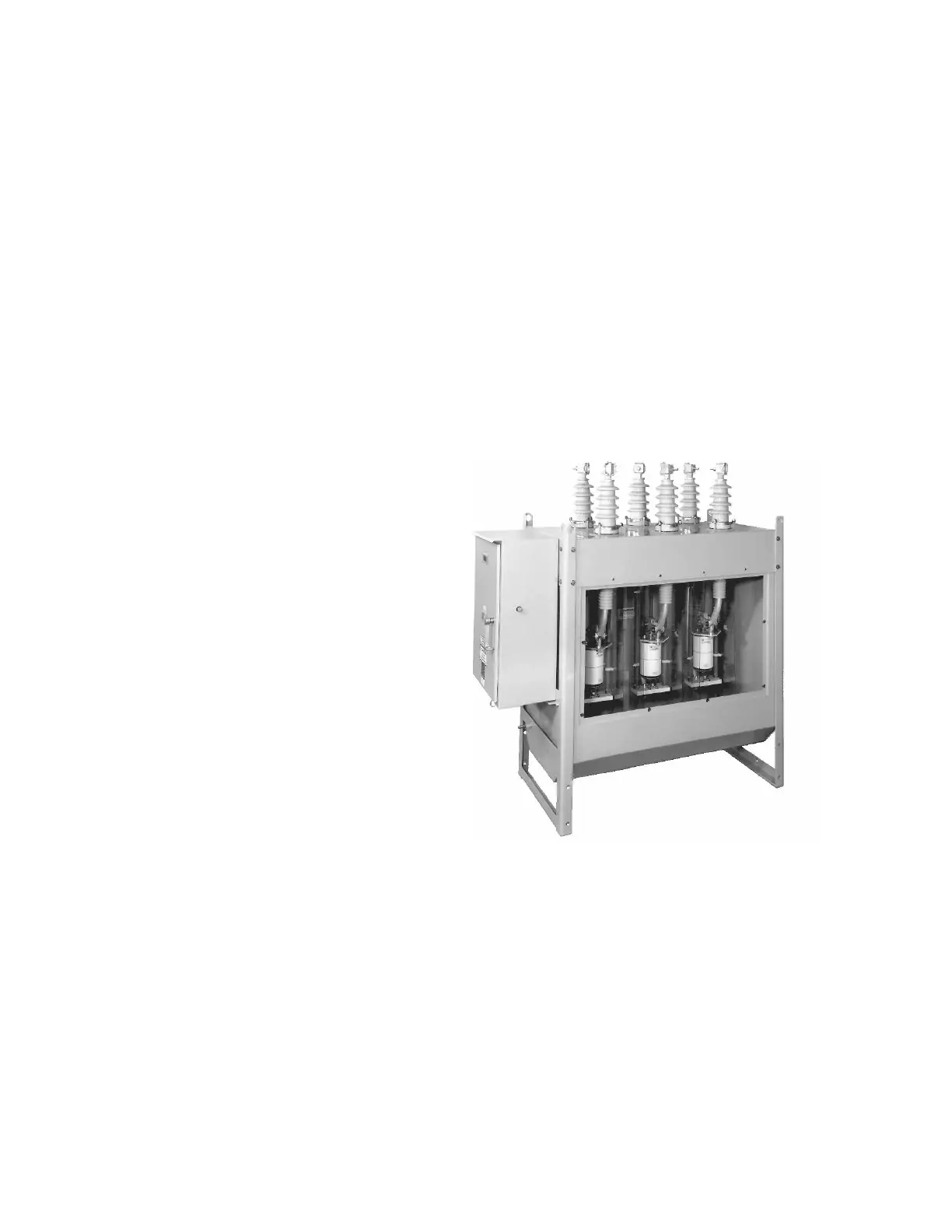

Major parts and assemblies of the VSA recloser are shown

in Figures 1 and 2. Being aware of the location of these

components and their part in the operation of the recloser

will give a quicker and clearer understanding of the recloser

maintenance and repair procedures that follow.

Figure 1. Type VSA recloser with side panels removed

Loading...

Loading...