Type VSA12, VSA16 and VSA20/800 maintenance instructions

9 MAINTENANCE INSTRUCTIONS MN280064EN October 2017

10. Remove two 3 ⁄ 8 inch hex nuts and lockwashers from

top of mechanism channel.

11. Remove 1 ⁄ 2 inch hex nut lockwasher attaching bottom

of channel to cabinet.

12. Remove 1 ⁄ 2 inch hex head bolt and lockwasher

attaching top of mechanism channel.

13. Maneuver complete mechanism assembly out of

operator cabinet.

Mechanism installation

Installation of the operating mechanism is essentially the

reverse of disassembly; however, two adjustments must be

made after the mechanism is installed.

External Quick-Close pullring adjustment. The stop

nut that secures the external quick-close pullring must be

adjusted to prevent over travel of the manual close lever

assembly, refer to Figure 13.

1. From under the mechanism housing, pull quick-close

lever down until linkage comes to its mechanical stop.

2. Adjust stop nut until the top edge of the manual close

lever just contacts the spacer.

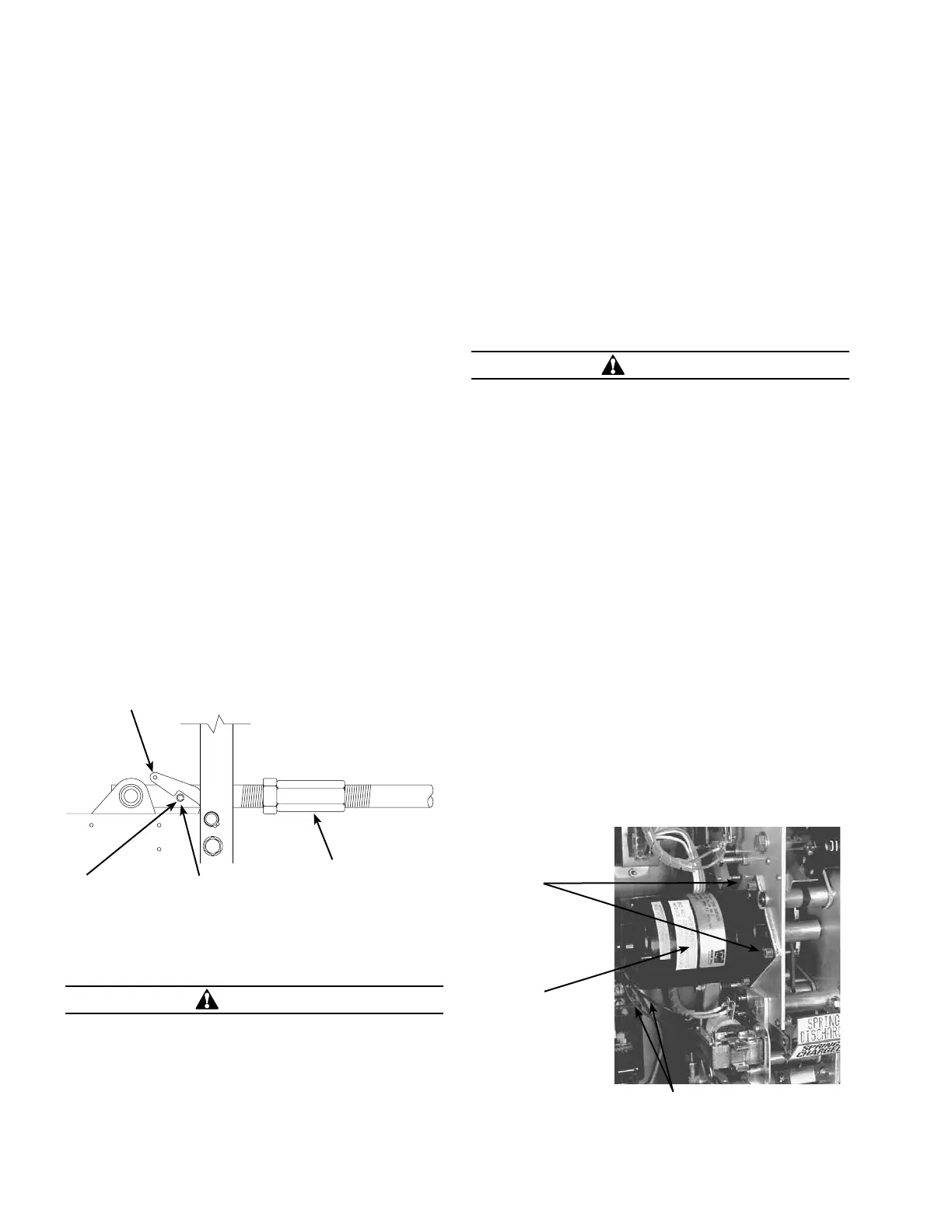

Anti-bounce latch adjustment. The anti-bounce latch

assembly must be properly adjusted to operate properly,

refer to Figure 14.

1. Loosen operating bar turn-buckle.

2. Adjust turnbuckle to provide a 1⁄32 inch gap between

operating bar roll pin and the anti-bounce latch.

3. Secure turnbuckle.

latch assembly

Roll pin

Operating bar

turnbuckle

Figure 14. Anti-bounce latch adjustment

Motor

CAUTION

This type of motor should NEVER be energized while

disconnected from gear reduction unit. Uncontrolled

motor speed will result when operated without load,

excessive speed will damage motor.

A universal series-type motor is used to charge the closing

springs. The motor is energized from either a 240- or

120-Vac auxiliary power source, through a fused pullout

switch. The motor has permanently lubricated, sealed ball-

bearings that require no service. Periodically check motor

brushes for wear or burning, replace as required.

ote:N Brush replacement kits are available for both the

240- Vac and 120-Vac motors. The kit consists of two

brushes and two brush caps.

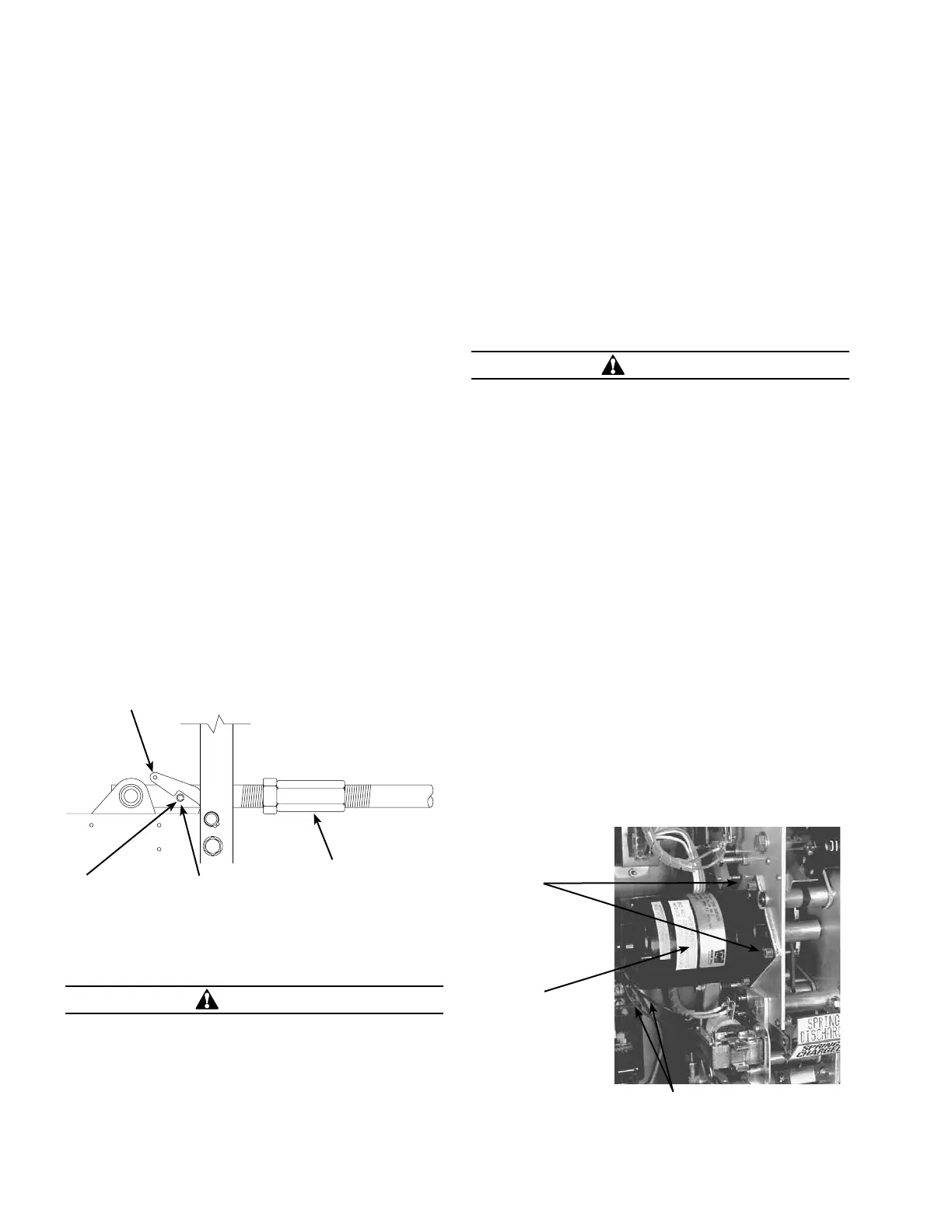

Motor replacement

The universal drive motor must be replaced, as an

assembly, if it become damaged or worn. To replace the

motor proceed as follows, refer to Figure 5:

CAUTION

Do not attempt to replace the drive motor while recloser

contacts are closed, or while operator springs are charged.

If the operator assembly were to trip while hands are

within operating linkage personal injury couldresult.

1. Remove fused pullout switch to de-energize AC power

source to operator mechanism.

2. Make sure recloser contacts are open; manually

operate mechanism until contact position indicator

reads OPEN and closing spring status indicator reads

SPRINGS DISCHARGED.

3. Cut motor leads, close to old motor.

4. Remove hardware securing motor and carefully remove

from operator assembly.

5. Position replacement motor into operator assembly,

engage motor shaft into coupling, secure with hardware

removed. Apply Loctite #242 (blue) to screw threads

prior to assembly.

6. Trim motor leads, leave sufficient length to splice new

motor leads to old motor leads.

7. Slide shrink tube over motor leads, splice and solder

leads. Shrink tubes over joints.

8. Install fused pullout switch to energize AC

powersource.

Drive motor

hardware

Universal

drive motor

Motor leads

Figure 15. Motor replacement

Loading...

Loading...