2 – 6

VSS/VSR/VSM/VSH/VSSH Compressor • Installation, Operation and Service Manual • Emerson • 35391S

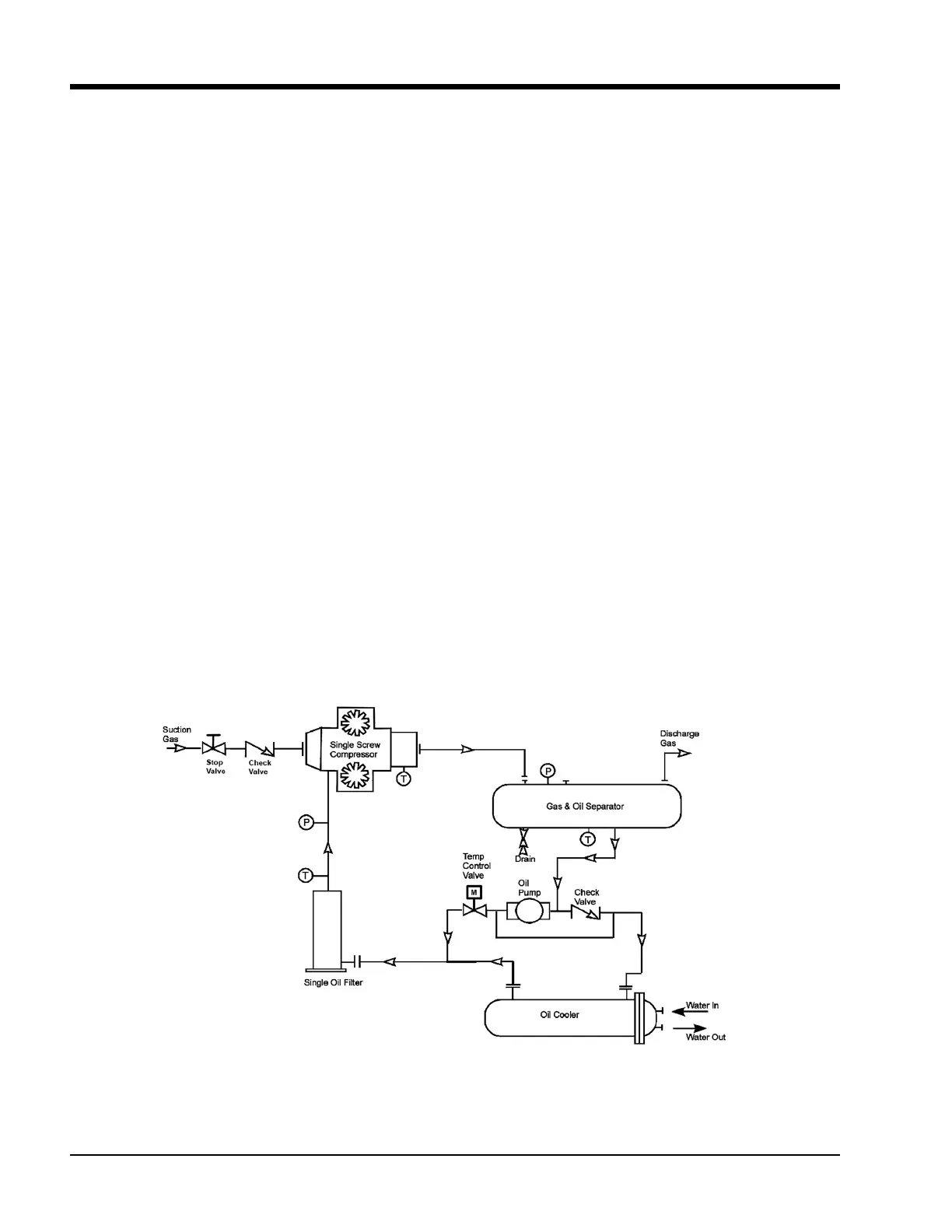

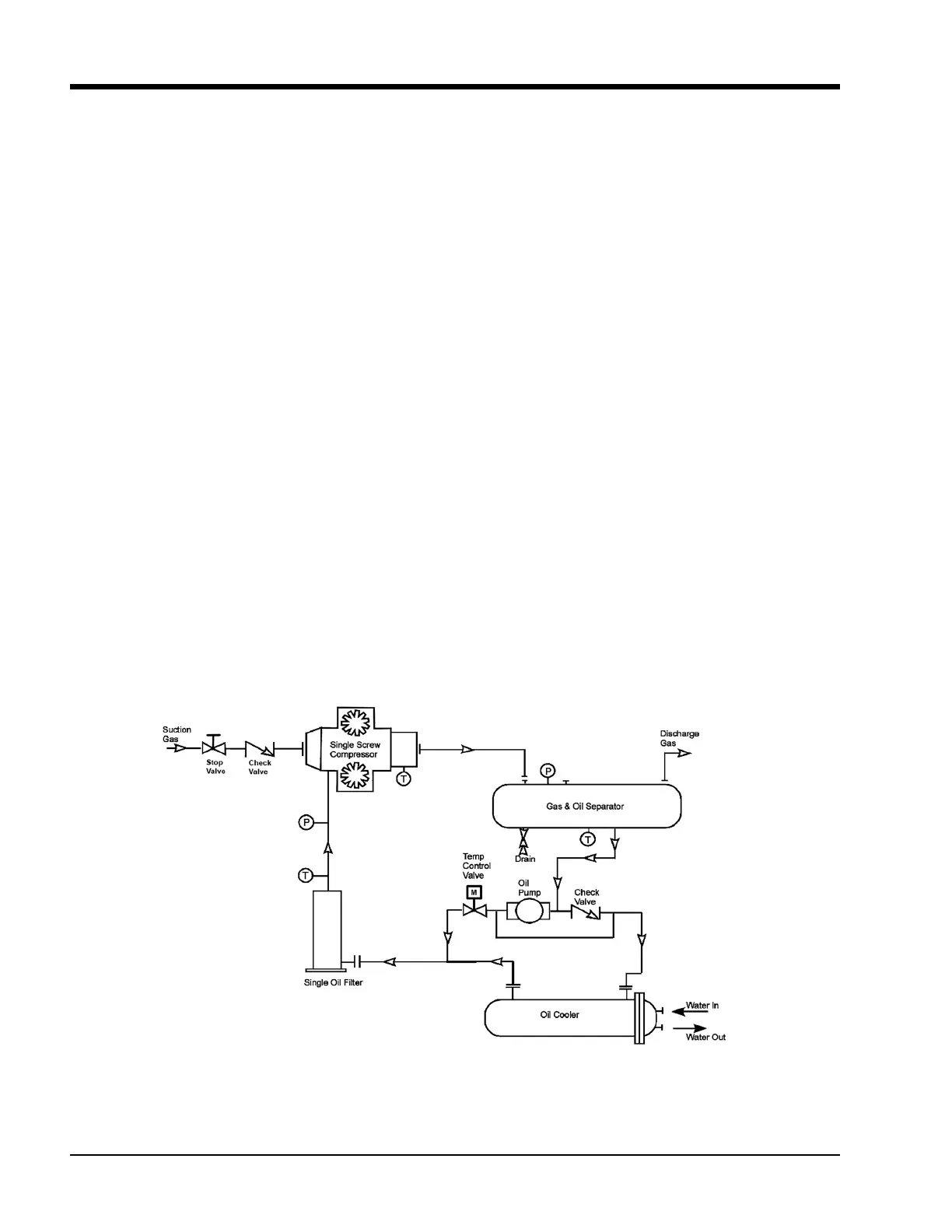

Section 2 • Theory of Operation

Single Screw Package Requirements

Process Gas Circuit

1. Suction Gas Stop/Check Valve - The Single Screw

compressor requires a manually operated stop valve on

the suction line to the compressor to allow for isolating

the compressor package from process gas. Also, a check

valve is required in the suction line to limit reverse rota-

tion of the compressor on shutdown.

2. Suction Line Strainer - Vilter

TM

strongly recommends

the use of an in-line suction gas strainer to protect the

Single Screw compressor from foreign material which

may enter the compressor with the suction gas. This

strainer is generally of stainless steel mesh construction.

3. Process Gas/Oil Separator - A separator vessel ca-

pable of removing the oil from the discharge gas stream

with an efciency down to at least 5 PPM oil carryover

is required. Vilter’s own available horizontal or vertical

separator is an ASME-coded vessel which uses ve stages

of separation to achieve an oil loss of as little as 3 to 4

PPM.

4. Discharge Gas Relief Valve - To protect the compres-

sor package from damage due to over pressurization, a

relief valve must be installed inside of any discharge line

hand block valves. The relief valve must be set to open at

a pressure lower than the Maximum Allowable Working

Pressure (MAWP) of the separator.

5. Oil Prelube Pump - Usually a direct driven gear type

pump, the oil pump is required to prelube the compres-

sor prior to starting and to maintain oil pressure during

any periods of low compression ratio operation.

6. Oil Cooler/ Temperature Control Valve - An oil cooler,

either air or water cooled, must be used to remove the

heat of compression from the oil stream. A temperature

control valve is used to maintain constant oil injection

temperature to the compressor.

7. Oil Filtration - Large capacity micronic oil lters are

required to lter the oil before injection into the Single

Screw compressor. Filtration down to 25 microns nomi-

nal or less is generally acceptable. Dual lters are recom-

mended to allow replacement of one cartridge while the

compressor continues running with the other cartridge

in service. If needed, separate oil ltration can be avail-

able for bearings and shaft seal.

8. Oil Heater - An oil heater is generally required and

must be sized to maintain oil temperature of at least

90°F when the compressor is not running. For outdoor

installations, low ambient temperatures and winds must

be considered when sizing the oil heater. Also, insulating

the separator and oil piping may be required in low tem-

perature ambient conditions.

Figure 2-2. Basic Single Screw Compressor System

Loading...

Loading...