5 – 29

Section 5 • Maintenance/Service

VSS/VSR/VSM/VSH/VSSH Compressor • Installation, Operation and Service Manual • Emerson • 35391S

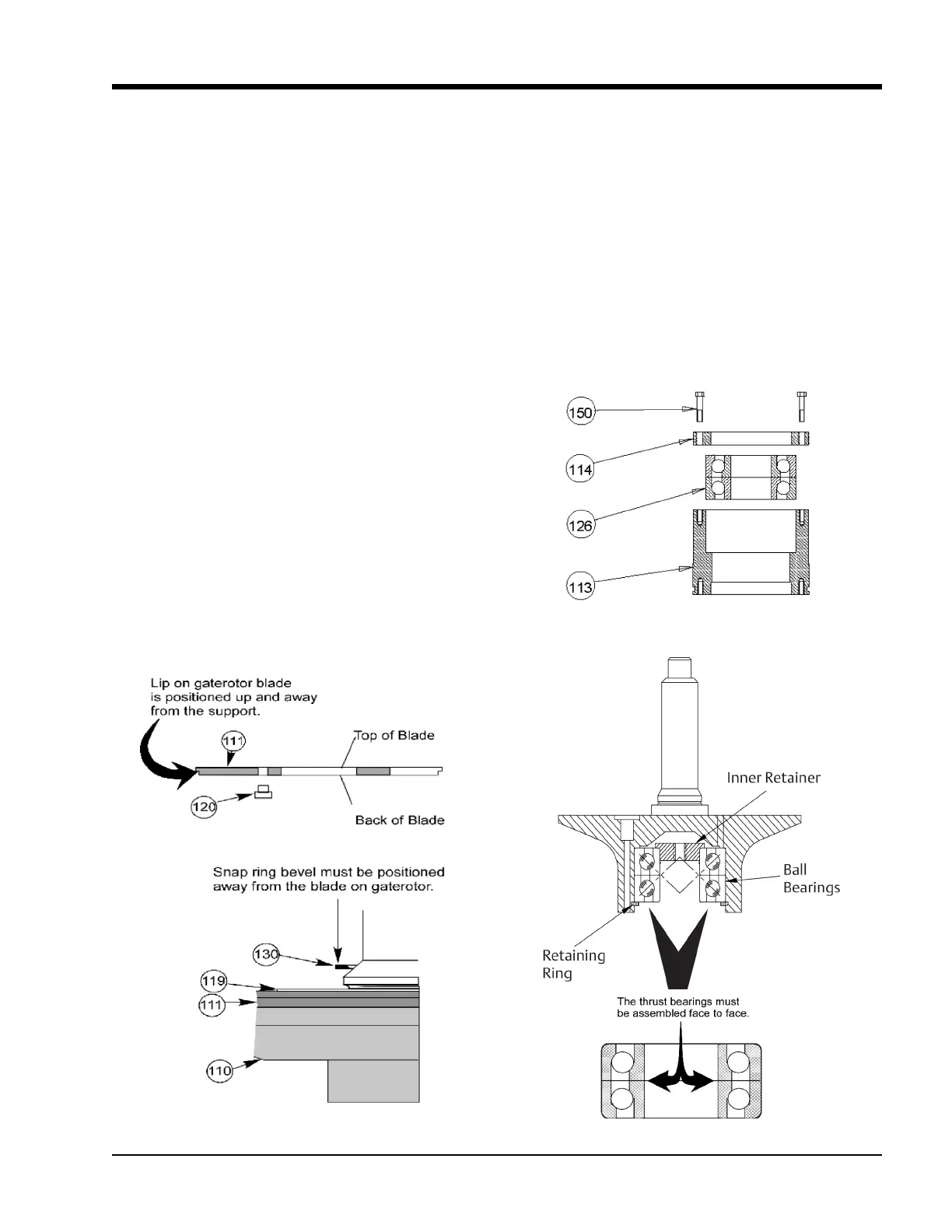

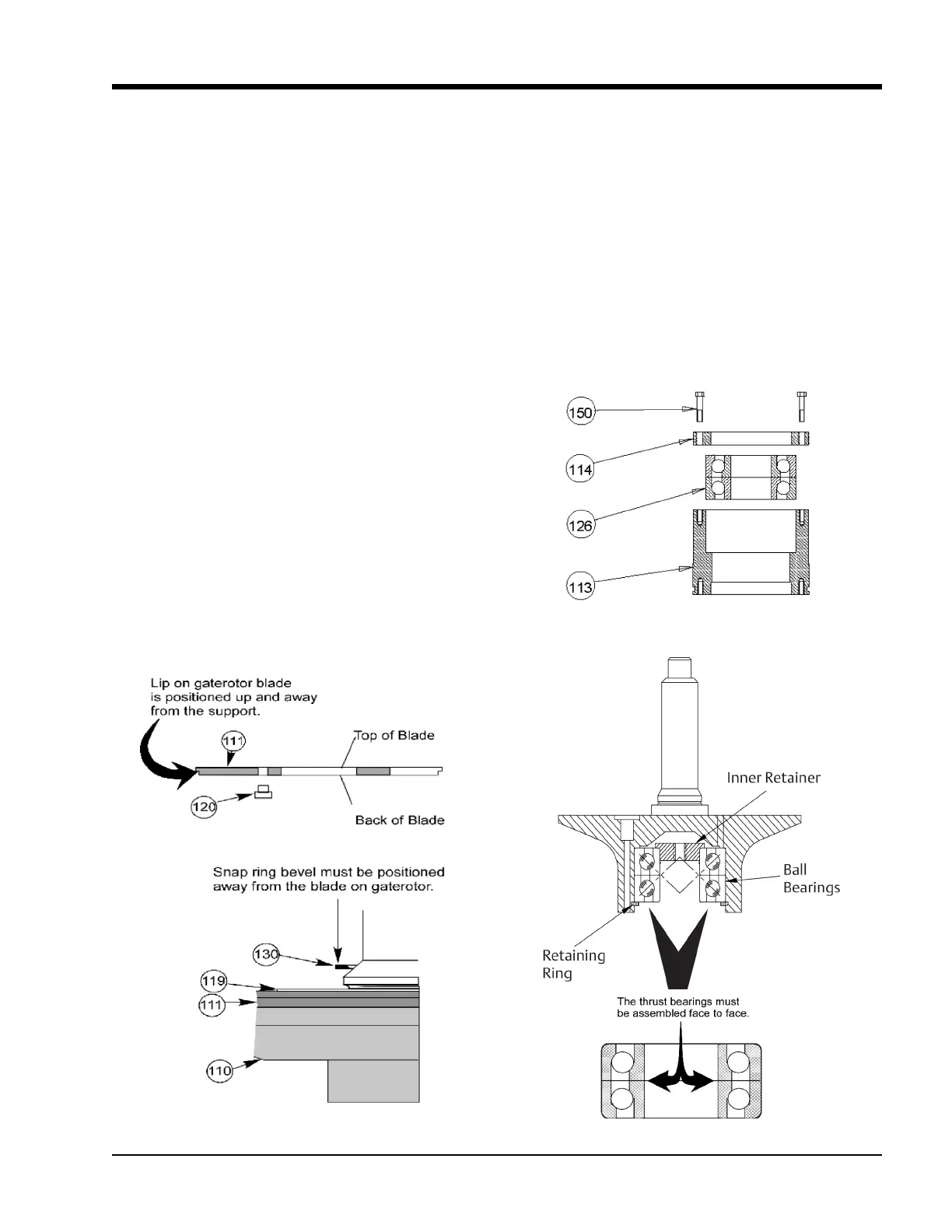

Gaterotor Thrust Bearing Installation

For installation of thrust bearings on VSS units

22. Install thrust bearings (126) in the housing so the

bearings are face to face. The larger sides of the in-

ner races are placed together. A light application

of clean compressor lubricating oil should be used

to ease the installation of the bearings into the

housing.

23. Center the bearing retainer ring on housing, use

Loctite® 242-thread locker and evenly tighten

the bolts to the recommended torque value, see

Figure 5-34.

Figure 5-32. Gaterotor Blade Installation

Figure 5-33. Gaterotor Thrust Bearing

Gaterotor Blade Installation

13. Install damper pin bushing (120) in gaterotor blade

(111) from the back side of the blade. Be sure bush-

ing is fully seated using red Loctite (271).

14. Place blade assembly on gaterotor support.

Locating damper over pin.

15. Install washer (119) and snap ring (130) on gatero-

tor assembly. The bevel on the snap ring must face

away from the gaterotor blade. After the gaterotor

blade and support are assembled, there should be

a small amount of rotational movement between

the gaterotor and support.

Gaterotor Thrust Bearing Removal

For removal of thrust bearings on VSM units:

16. Remove bolts (150) from the clamping ring (114),

see Figure 5-33.

17. Remove thrust bearing clamping ring.

18. Remove thrust bearings (126) from housing (113).

For removal of thrust bearings on VSS units:

19. Remove retaining ring from gaterotor support.

20. Remove bearings from support.

21. Remove bearing retainer from inner race.

Figure 5-34. Thrust Bearing Installation

Loading...

Loading...