3 – 12

Section 3 • Installation

VSS/VSR/VSM/VSH/VSSH Compressor • Installation, Operation and Service Manual • Emerson • 35391S

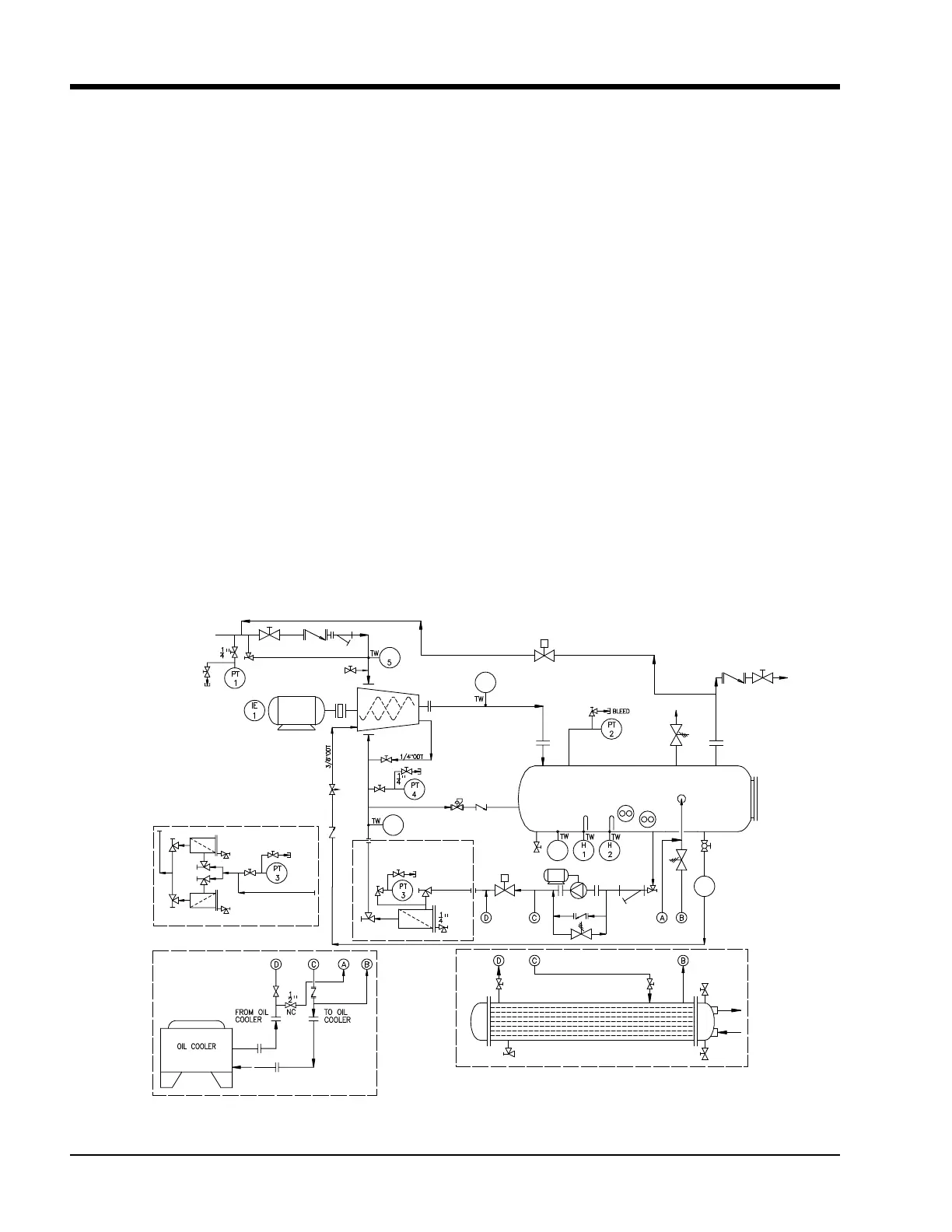

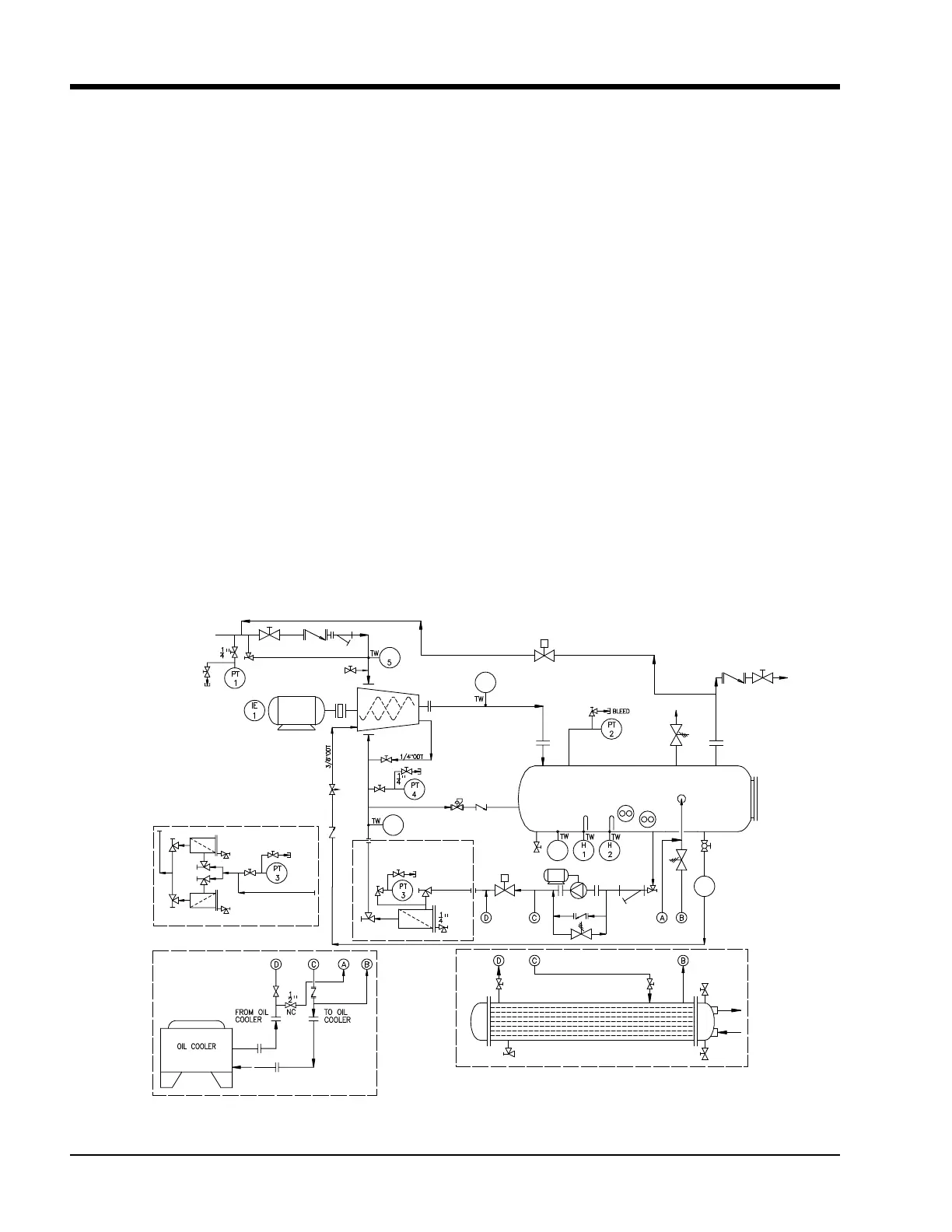

Instrumentation Requirements

Pressure

There are four pressure transducers required to read sys-

tem pressures as listed below (see Figure 3-9):

1. Suction Pressure Transducer - (15.0 - 1000 PSIG)

measures the gas suction pressure into the compressor

housing, which provides the permissive to start at reach-

ing minimum suction pressure, and is used to detect low

suction pressure while running and in the capacity con-

trol logic.

2. Discharge Pressure Transducer - (15 – 1000 psig)

measures the discharge pressure of the process gas in

the separator, which provides detection of high dis-

charge pressure, and may also be used for capacity con-

trol logic.

3. Oil Filter Inlet pressure transducer - (15 – 1000 psig)

measures the oil pressure as it enters the oil lter canis-

ters and is used to calculate oil lter differential pressure

to provide detection of high lter differential pressure.

4. Oil Manifold pressure transducer - (15 – 1000 psig)

measures the oil pressure downstream of the oil lter as

the oil is injected into the compressor, and provides de-

tection and protection against low prelube oil pressure,

and low running oil injection pressure.

OIL SEPARATOR

OPTIONAL DUAL OIL FILTERS

STANDARD SINGLE

OIL FILTER

COMPRESSOR

FILTER

FILTER

DRAIN

DRAIN

BLEED

FILTER

BLEED

DRAIN

DRAIN

BLEED

SUCTION GAS

1/4” OIL CHARGING

1/4”

100#

DISCHARGE

STOP VALVE

MOTOR

BLEED

S

MOTOR

M

PUMP

CHECK

VALVE

TE

TE

FG

1

6

TE

7

TE

8

OPTIONAL REMOTE AIR COOLED OIL COOLER

STANDARD WATER COOLED OIL COOLER

OIL COOLER

DRAIN

VENT

OIL

DRAIN

Figure 3-9. Additional Instruments

Additional pressure transducers may be required and

installed by the customer for pressure readings at cus-

tomer specied points such as process gas discharge

pressure from the package boundary, cooling water

pressure to and/or from the oil cooler, etc.

Temperature

There are four pressure temperature readings required

for processor control, as listed below (see Figure 3-9):

5. Suction temperature RTD - measures the tempera-

ture of the incoming suction gas, and is used to provide

detection of low suction temperature when the unit is

running.

6. Discharge temperature RTD - measures the tempera-

ture of the gas/oil mixture as it is discharged from the

compressor housing, and provides detection of high

running discharge temperature.

7. Oil Separator temperature RTD - measures the tem-

perature of the oil in the separator sump, and produces

the oil temperature start permissive and detection of

low running separator temperature.

8. Oil Injection temperature RTD - measures the tem-

perature of the oil as it is injected into the compressor,

which provides detection of either high or low running

oil injection temperature.

Loading...

Loading...