3 – 1

Section 3 • Installation

VSS/VSR/VSM/VSH/VSSH Compressor • Installation, Operation and Service Manual • Emerson • 35391S

NOTICE

Vilter compressors are to be installed and connected

to the customer-provided piping. Vilter expects this

piping to be designed and built following ASME B31.3

Process Piping Guide, plus any other local applicable

codes, and that the installation will be performed by

qualifi ed personnel only.

Delivery Inspection

Every equipment supplied by Vilter is thoroughly in-

spected at the factory. However, damage can occur in

shipment. For this reason, the compressor should be

thoroughly inspected upon arrival, prior to off-loading.

Any damage noted should be photographed and report-

ed immediately to the transportation company. This

way, an authorized agent can examine the compres-

sor, determine the extent of damage and take neces-

sary steps to rectify the claim with no serious or costly

delays. At the same time, the local Vilter representa-

tive or the home ofce should be notied of any claims

made within ten (10) days after its discovery. Refer to

Compressor Inspections Prior to Installation for addi-

tional recommendations.

Rigging and Lifting of the Compressor

WARNING

When rigging and lifting a compressor unit, use proper

lifting device capable of lifting and maneuvering the

weight and size of the compressor unit. Use only

qualifi ed personnel and additional personnel and

lifting equipment (i.e. spreader bar) as required.

Failure to comply may result in death, serious injury

and/or damage to equipment.

Only qualied personnel shall operate rigging and lifting

equipment. Ensure that the lifting device is capable of

lifting the weight of the compressor, refer to the sup-

plied Vilter General Assembly (GA) drawing, and to Table

3-1 for weights of bare shaft compressors.

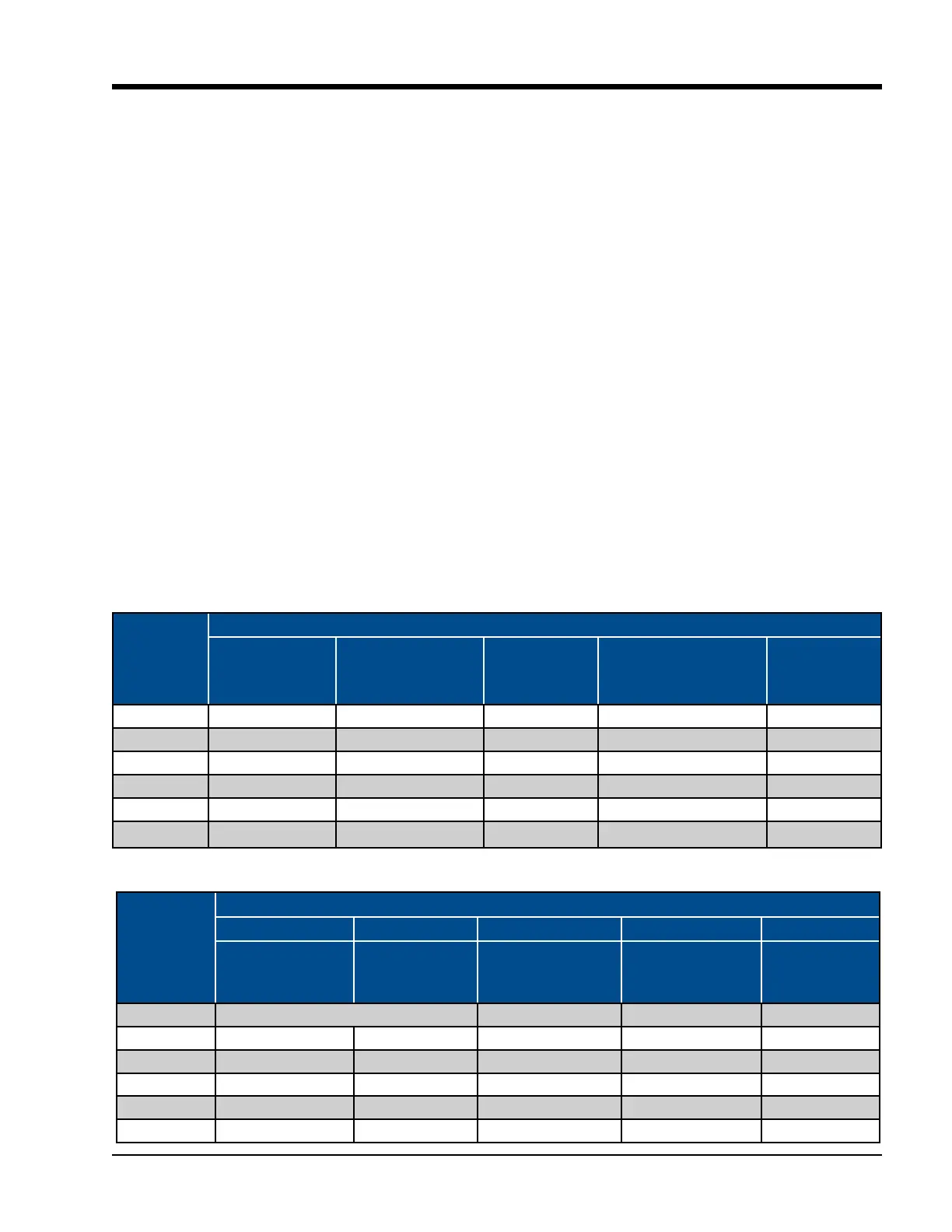

Models

Component Weights

Gaterotor

Bearing Housing

Gaterotor Bearing

Housing Cover

Discharge

Manifold

Main Compressor

Assembly ONLY

Gaterotor

Cover

97-127 3.3 lbs (1.6 kg) 8 lbs (4 kg) N/A 249 lbs (113 kg) 10 lbs (5 kg)

291-601 19 lbs (9 kg) 11 lbs (5 kg) 125 lbs (57 kg) 1105 lbs (502 kg) 46 lbs (21 kg)

751-901 28 lbs (13 kg) 11 lbs (5 kg) 177 lbs (80 kg) 1450 lbs (658 kg) 33 lbs (15 kg)

1051-1301 37 lbs (17 kg) 13 lbs (6 kg) 274 lbs (125 kg) 2006 lbs (910 kg) 42 lbs (19 kg)

1501-2101 54 lbs (24 kg) 19 lbs (9 kg) 349 lbs (158 kg) 3151 lbs (1429 kg) 70 lbs (32 kg)

2401-3001 58 lbs (27 kg) 32 lbs (15 kg) 788 lbs (358 kg) 4152 lbs (1883 kg) 150 lbs (68 kg)

Table 3-1. Bareshaft Compressor Component Weights

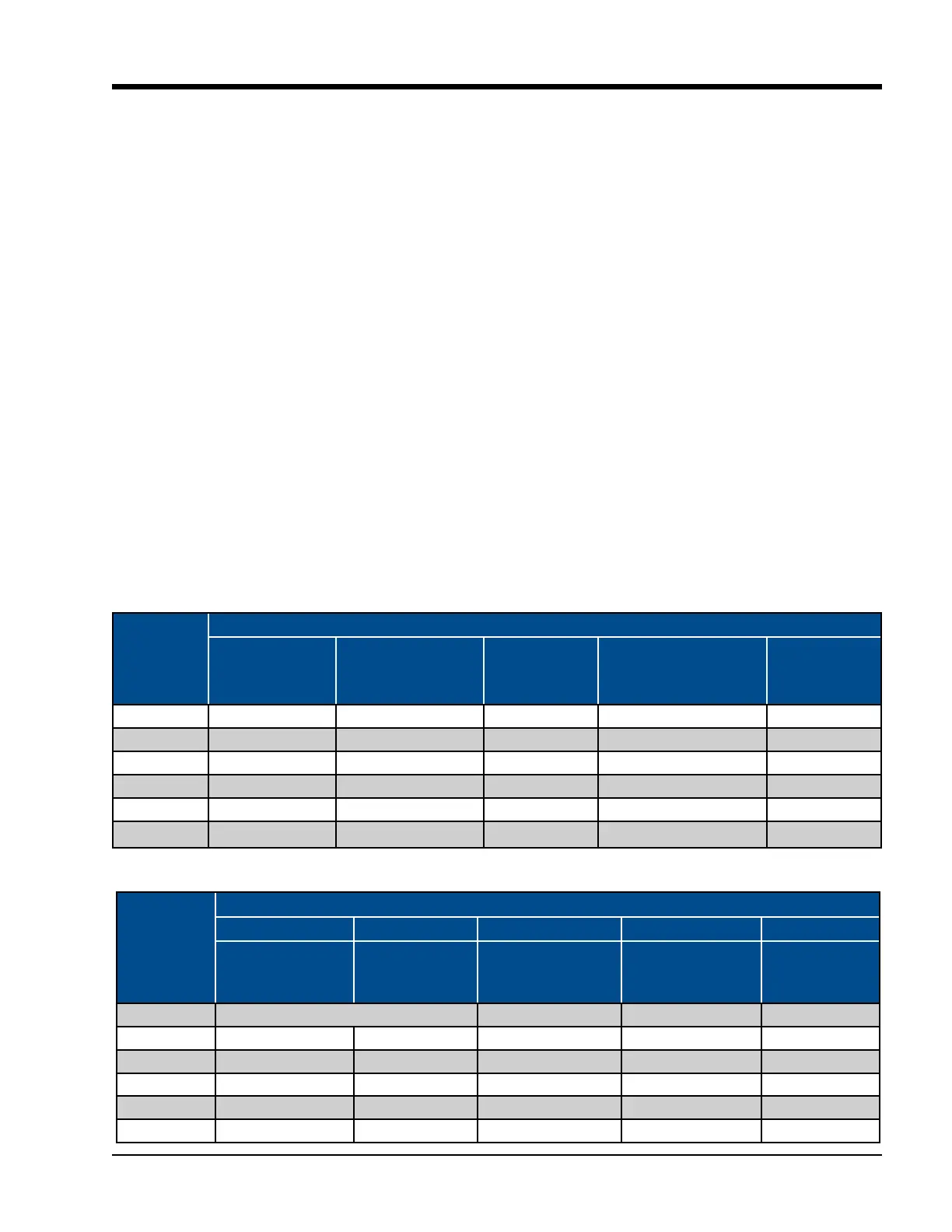

Models

Component Lifting Hole Sizes

A B C D E

Discharge

Manifold (Side)

Discharge

Manifold (Top)

Main Compressor

Assembly ONLY

(Discharge)

Main Compressor

Assembly ONLY

(Suction)

Gaterotor

Cover

97-127 A & B Lifting Points: 1/2 - 13 UNC -2B - - -

291-601 5/8-11 UNC -2B 5/8-11 UNC -2B 5/8-11 UNC -2B 5/8-11 UNC -2B 3/8-16 UNC-2B

751-901 5/8-11 UNC -2B 5/8-11 UNC -2B 5/8-11 UNC -2B 5/8-11 UNC -2B -

1051-1301 5/8-11 UNC-2B 5/8-11 UNC -2B 3/4-10 UNC -2B 5/8-11 UNC -2B 3/8-16 UNC -2B

1501-2101 5/8-11 UNC -2B 5/8-11 UNC -2B 5/8-11 UNC -2B 5/8-11 UNC -2B 3/8-16 UNC -2B

2401-3001 5/8-11 UNC -2B 5/8-11 UNC -2B 5/8-11 UNC -2B 3/4-10 UNC -2B 5/8-11 UNC -2B

Table 3-2. Bareshaft Compressor Component Lifting Hole Sizes

Bareshaft Compressor Lifting Points and Weights

Loading...

Loading...