5 – 15

Section 5 • Maintenance/Service

VSS/VSR/VSM/VSH/VSSH Compressor • Installation, Operation and Service Manual • Emerson • 35391S

Gaterotor Bearing Inspection

1. Position a one gallon (at least) plastic oil collec-

tion bin beneath the side cover. Carefully pry

open the side cover to allow the oil to drain before

nally re moving the side cover.

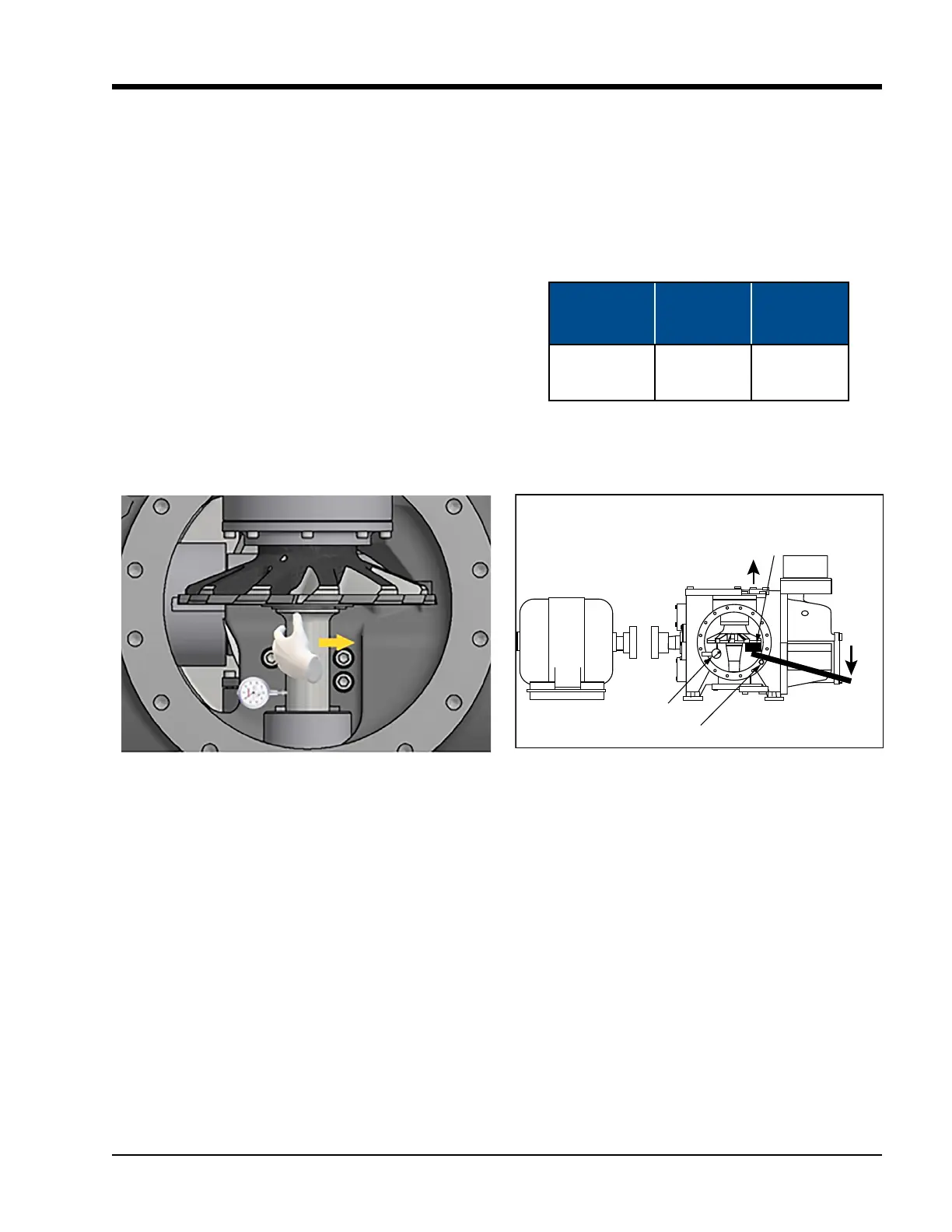

2. To measure the gaterotor radial bearing clear-

ance, position a dial indicator to the gaterotor

shaft as shown in Figure 5-10 (a) and zero the

indicator. Put a hand as shown and rmly move

the shaft in the direction shown in Figure 5-10

(a). Record the measurement. See table 5-4 for

the maximum radial clearance value.

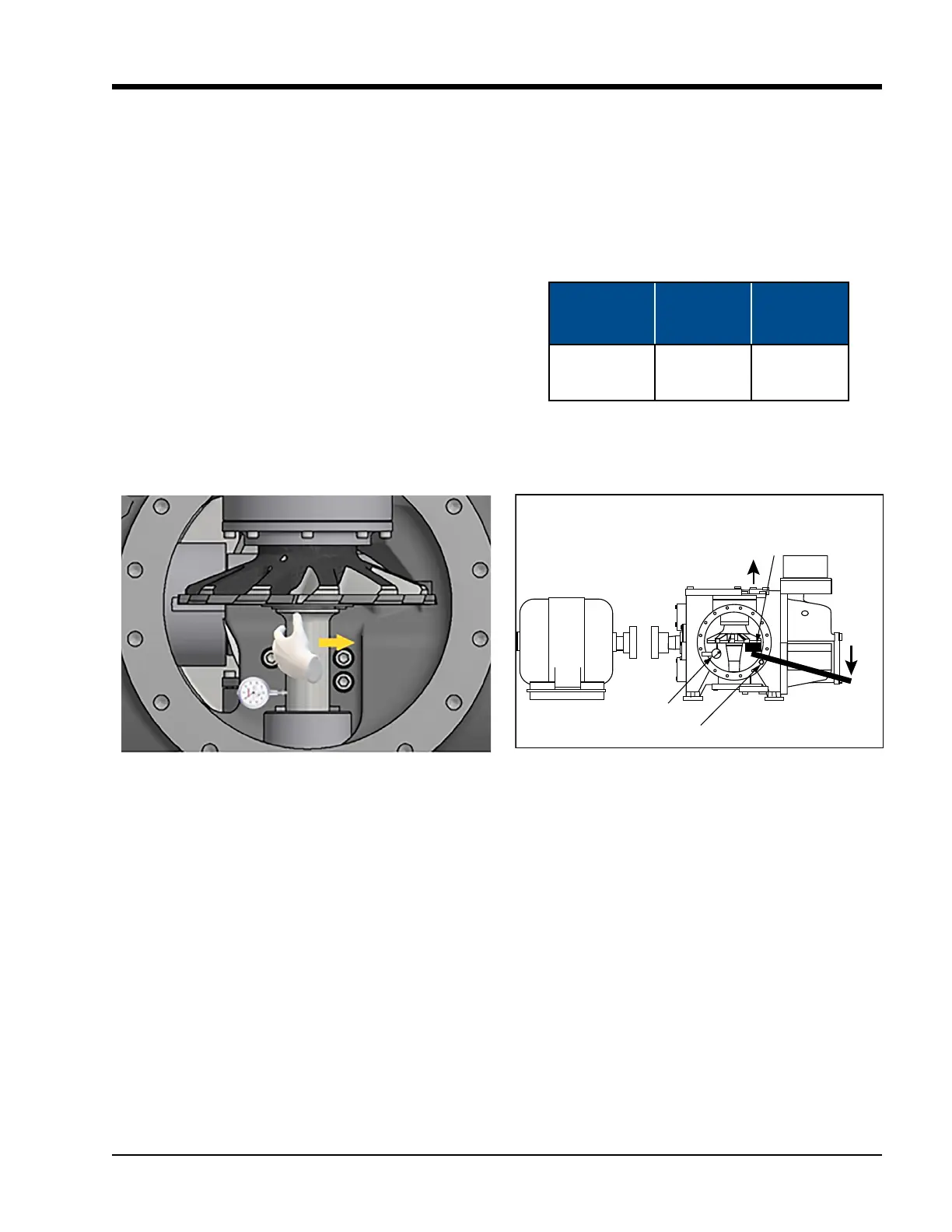

3. To measure the gaterotor axial bearing clear-

ance, position a dial indicator on the gaterotor,

as shown in Figure 5-10 (b).

Figure 5-10. Gaterotor Bearing Clearance

Force to be determined

by length of lev

er

arm.

Use bolt for fulcrum.

Rigidly at tach

dial indicator.

Side View

Wooden block to prevent

damage to gaterotor blade.

Showing gaterotor bearing clearance

being measured.

Direction of gaterotor movement.

Axial force at gaterotor to not

exceed 100 lbs.

Figure 5-10 (b): Axial

Figure 5-10 (a): Radial

Compresso r

Models

Max. Axial

Clearance

in (mm)

Max. Radial

Clearance

in (mm)

All Sizes

0.002”

(0.051 mm)

0.004”

(0.102 mm)

Table 5-4. Maximum Gaterotor

Bearing Clearance

4. To check axial bearing clearance use a lever arm

pivoting on a bolt with a small block of wood

against the gaterotor to protect it, as shown in

Figure 5-10 (b). Record the measurement. See

Table 5-4 for the maximum axial clearance value.

Loading...

Loading...