C8 Maintenance 9. Joint #5

366 C Series Maintenance Manual Rev.2

9.1 Joint #5 - Replacing the Motor

Name Qty. Note

Maintenance

Parts

AC servo motor 100 W 1

2172051

(Common for Joints #4, #5, #6)

Tools

Hexagonal

wrench

For M4 hexagon socket set screws

width across flats: 2.5 mm

For M3 hexagon socket head cap bolts

For M4 hexagon socket head cap bolts

Cross-point screwdriver (#2)

For cross recessed head screws

For tightening torque control

Spanner

(width across flats: 8 mm)

1 For air tube fitting

For adjusting the drive boss position

* The belt tensile jig is an assembly jig. Use the jig when adjusting belt tension.

The brake is mounted on each joint to prevent the arm from lowering due to its own weight while the Controller

power is OFF or the motor is OFF status. The brake does not work during replacement.

Be careful when performing maintenance work.

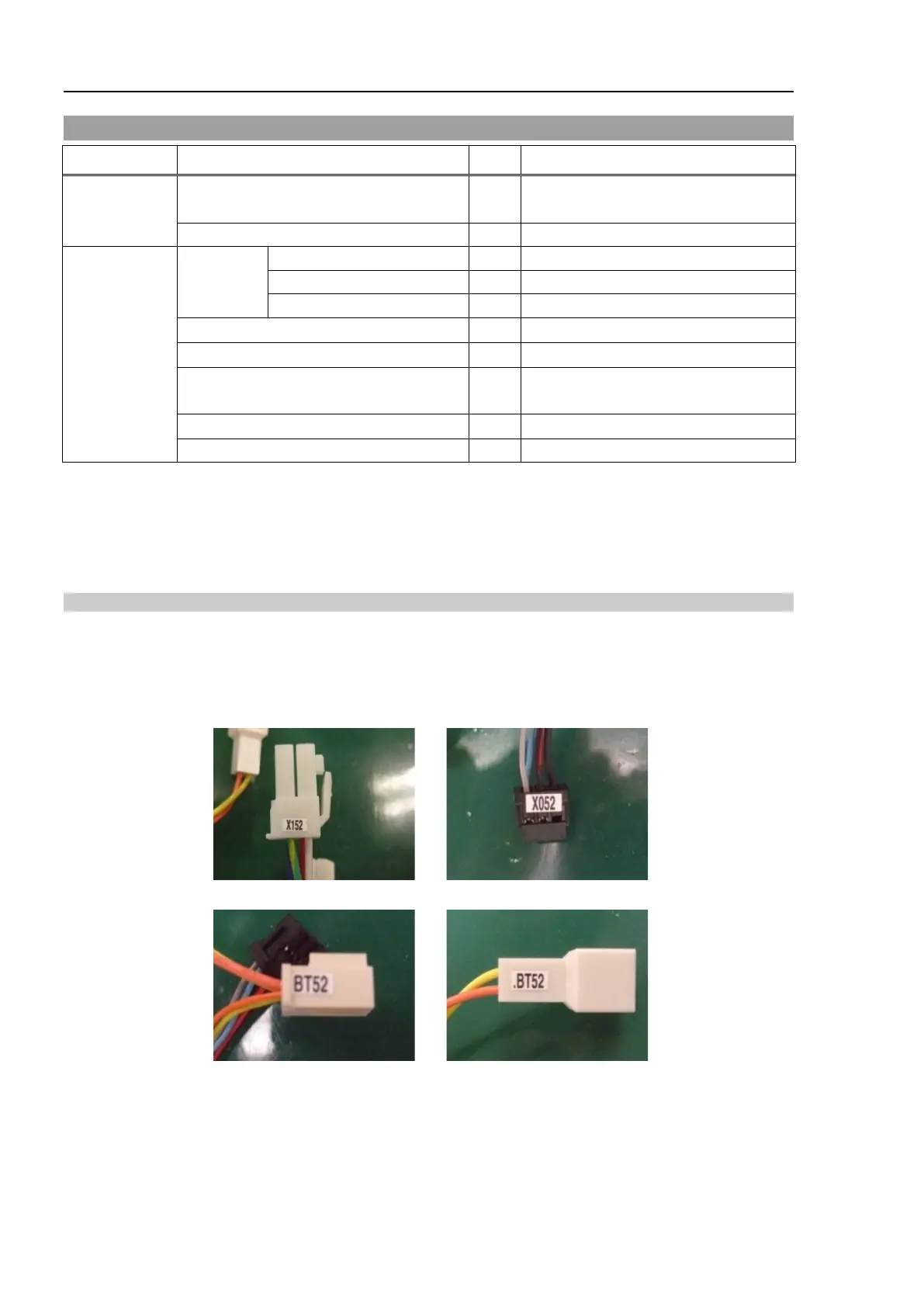

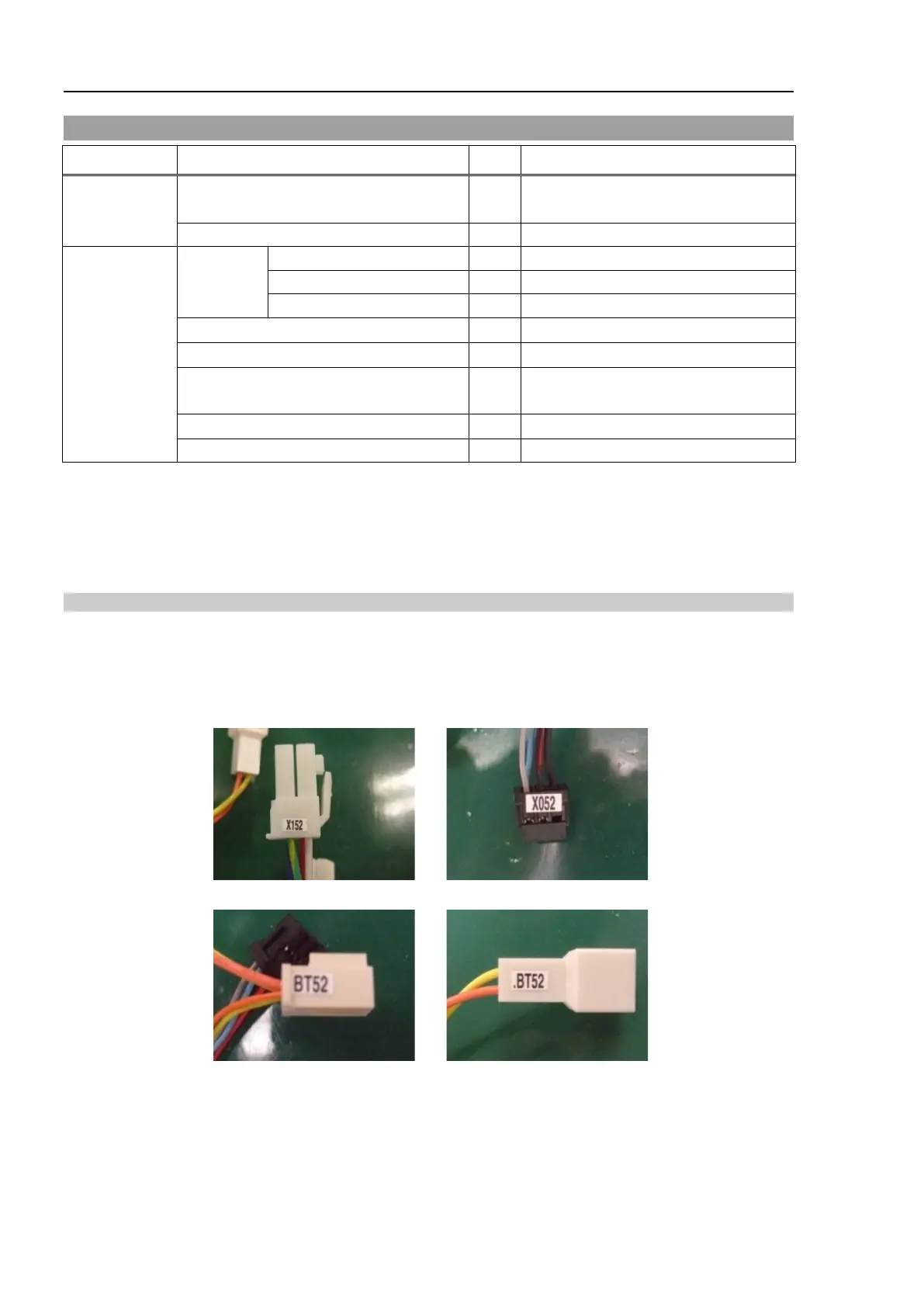

Attaching the labels

The motors are common for Joints #4, #5, and #6.

In order to prevent misconnection of the connectors, attach the label for the motor as shown

in the photos.

Joint #5 motor Locations of the connector labels

X152 X052

BT52 _BT52

Loading...

Loading...