7 TROUBLESHOOTING

0463 613 101

- 38 -

© ESAB AB 2020

7 TROUBLESHOOTING

Perform these checks and inspections before contacting an authorized service technician.

7.1 EWT1000

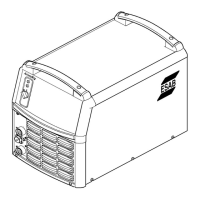

Type of fault Possible cause Action

No travel motion Poor electrical connection. Clean and tighten all electrical

connections.

Check cables.

Incorrect motor

speed

Error in encoder. No feedback

in the system.

Clean and tighten all electrical

connections.

Check cables.

7.2 EWH600/EWH1000

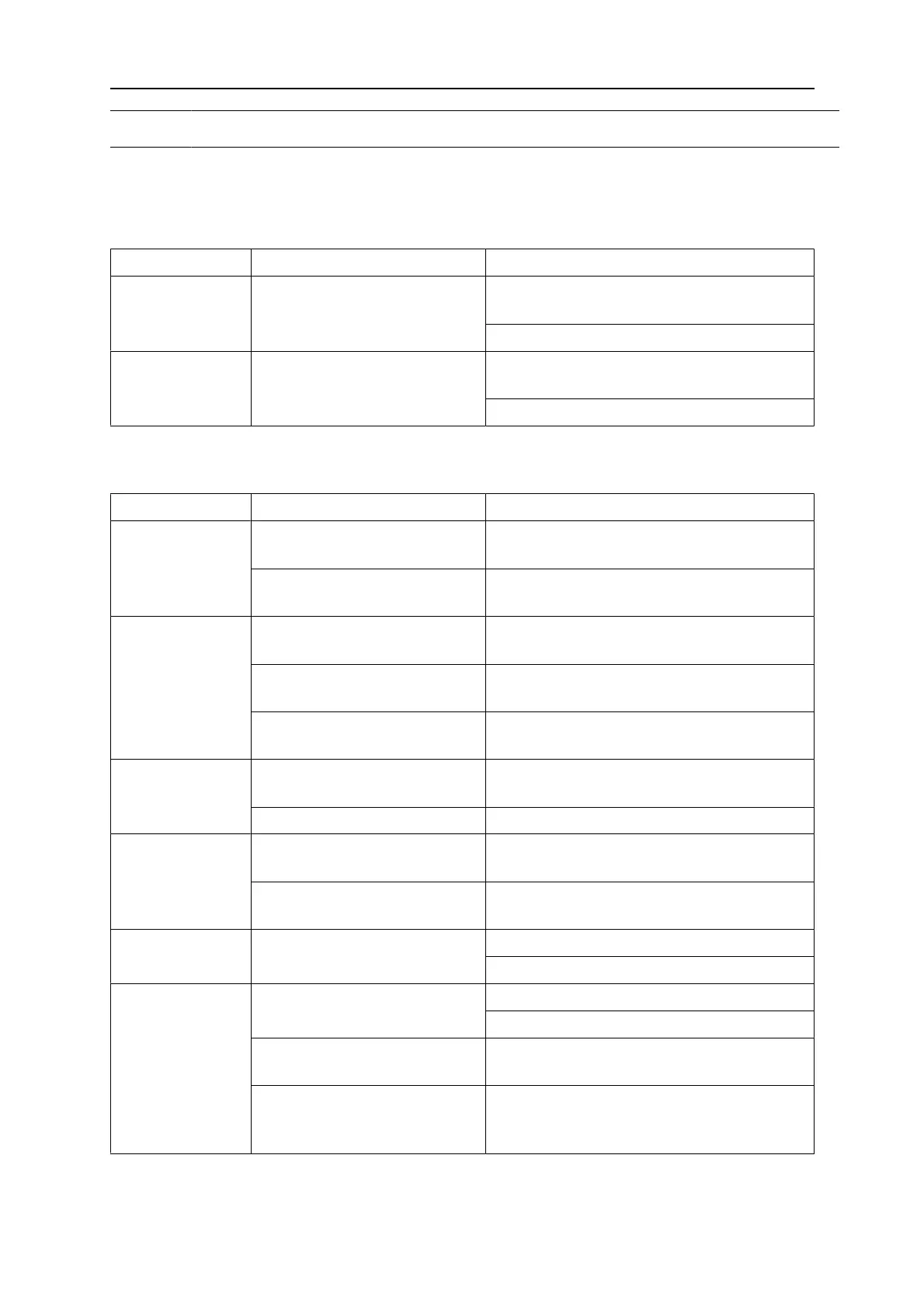

Type of fault Possible cause Action

Current and

voltage readings

show large

fluctuations

Contact jaws or nozzle are

worn or the wrong size.

Replace contact jaws or nozzle.

Wire feed roller pressure is

inadequate.

Increase pressure on wire feed rollers.

Wire feed is

uneven

Pressure on wire feed rollers

is set incorrectly.

Adjust pressure on wire feed rollers.

Wire feed rollers are the

wrong size.

Replace wire feed rollers.

Grooves in wire feed rollers

are worn.

Replace wire feed rollers.

Wire feed is not

functioning

Wire feed roller pressure is

inadequate.

Adjust pressure on wire feed rollers.

Wrong feed roller is used. Replace feed roller.

Welding cables

are overheating

Poor electrical connection. Clean and tighten all electrical

connections.

Cross-sectional area of

welding cables is too small.

Use cables with a larger cross-section or

use parallel cables.

Incorrect motor

speed

Error in encoder. No feedback

in the system.

Check the electrical connections.

Check cables.

Bad or no start of

welding or arc

ignition

Poor electrical connection in

welding cables.

Tighten the OKC connectors.

Check welding cables.

Poor connection for welding

wire.

Make sure that the welding wire is cut

straight.

Aristo 1000: Poor connection

for welding wire, no

(+)feedback.

Check the electrical connections. Check

cables.

Loading...

Loading...