channels.

There must be continuity between the smoke channel and the ue

so that the ue does not lean on the generator. The smoke channels

must not cross rooms where the installation of the combustion

appliances is not allowed.

The mounting of the smoke channels must be carried out in order

to guarantee smoke seal for the appliance functioning conditions,

limit the forming of condensate and avoid it being transported

towards the appliance.

The mounting of horizontal routes must be avoided.

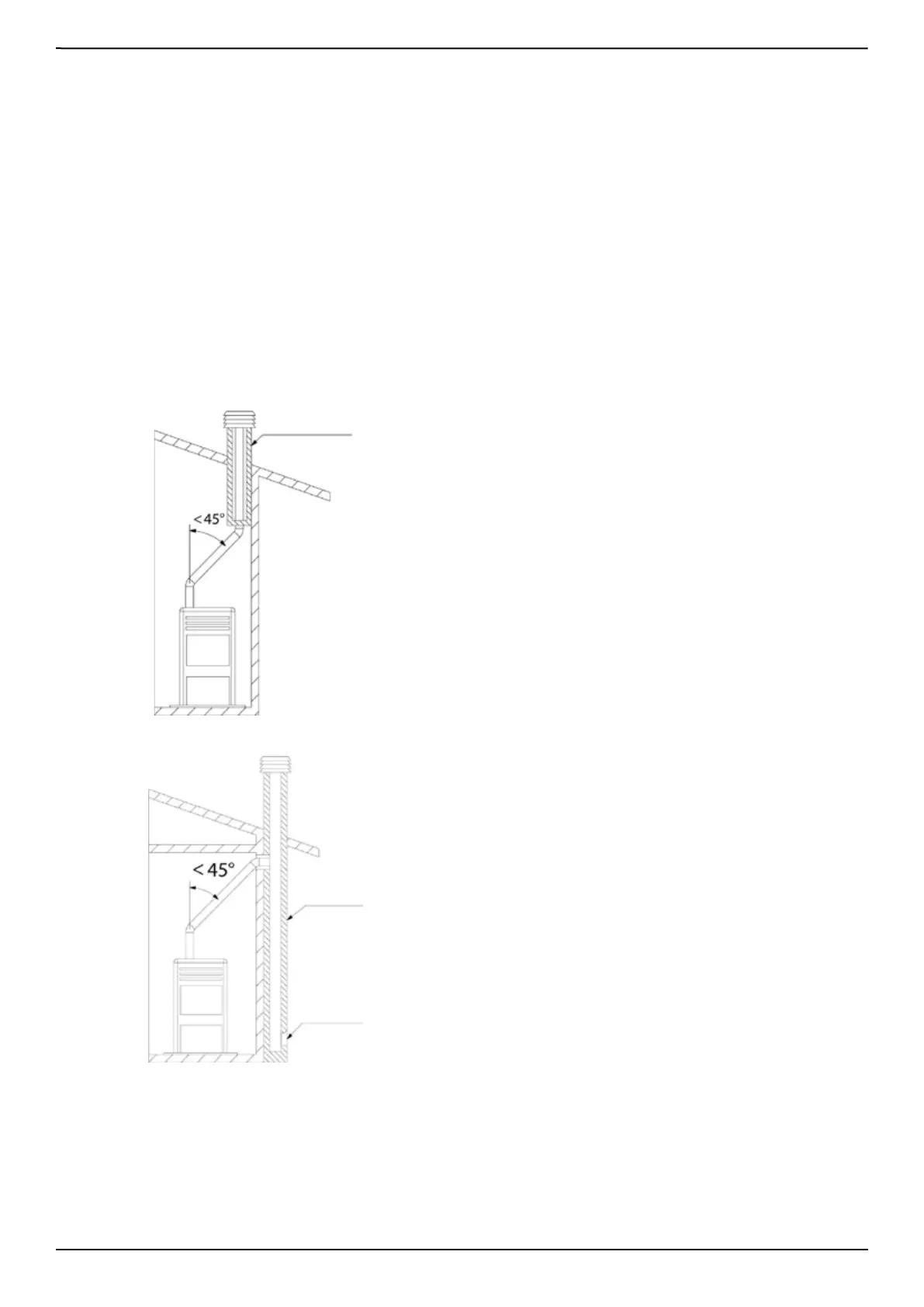

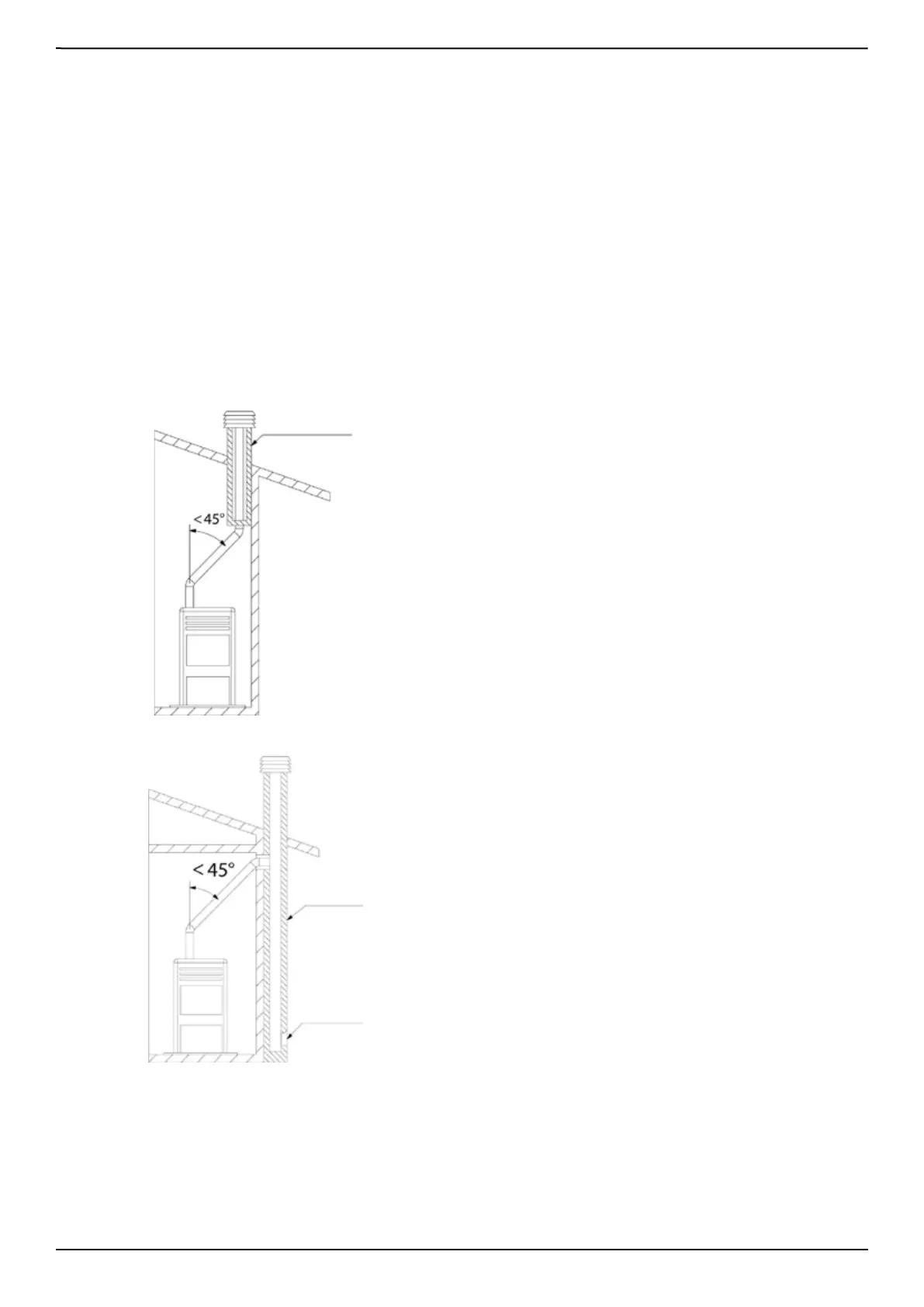

For appliances where ceiling or wall non-coaxial discharges with

respect to the appliance combustion product outlet have to be

reached, the direction changes will have to realised using open

bends not greater than 45° (see gures below).

For the heat generator appliances equipped with electric fan for

expelling combustion products, the instructions below must be

followed:

gure 8

Insulating

product

gure 9

Flue

Inspection

The horizontal routes will have to have a minimum upward

slope of 3%

The length of the horizontal route must be minimal and,

however, not longer than 3 metres

The number of direction changes including the one for eect

of using the "T" element must not be more than 4 (if 4 bends

are used, use double wall piping with an internal diameter of 120

mm).

In any case, the smoke channels must seal the combustion and

condensate products and be insulated if they pass outside the

installation room.

The use of counterslope elements is forbidden.

The smoke channel must allow the recovery of soot or be

brushable.

The smoke channel must have constant section. Any section

changes are only allowed at the ue coupling.

It is forbidden to have other air supply channels and pipes for

plant engineering, especially if over-sized, transit inside the smoke

channels. The mounting of manual draught adjustment devices on

forced draught appliances is forbidden.

CHIMNEY OR INDIVIDUAL FLUE10.3.2.

The chimney or individual ue must respond to the following

requisites:

seal the combustion products, be waterproof and adequately

insulated in line with the use conditions;

be realised with materials which resist the normal mechanical

stress, heat, action of the combustion products and any

condensate;

have mainly vertical progress with deviations from the axis

not greater than 45°;

be adequately distanced from fuel or ammable materials

through air space or opportune insulation;

have preferably circular internal section: the square or

rectangular sections must have round corners with a radius not

lower than 20 mm;

have constant internal section, free and independent;

have rectangular section with max. ratio between the sides

of 1.5.

It is recommended that the smoke pipe be equipped with a

collection chamber for solid materials and any condensate situated

under the smoke channel inlet, so that it can be easily opened and

inspected from airtight door.

DISTANCES RECOMMENDED FOR 10.3.3.

BOILER COMPARTMENT

Below nd images relative to the measurements that the company

recommends are respected.

For the “Lucrezia idro” model, respect the measurements for Lp14.

Loading...

Loading...