LP14_20_30 BOILER CLEANING

34

LP14_20_30 BOILER 20.

CLEANING

(Some images could be oset from the original model).

Maintenance operations guarantee correct functioning of the

product through time. Failure to comply with these operations can

jeopardise the safety of the product. The cleaning operations must

be performed when the stove is completely cold.

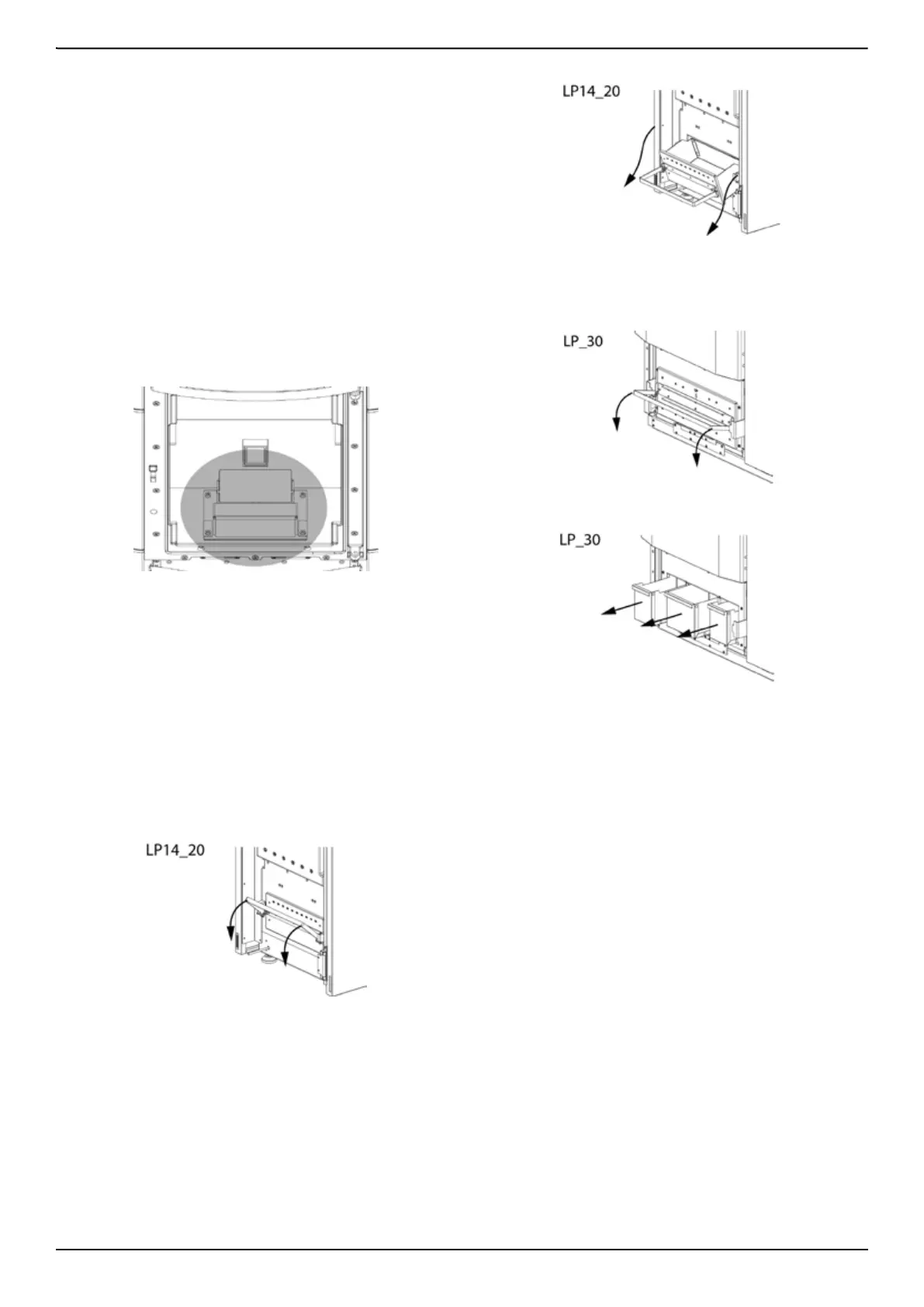

BURN POT CLEANING20.1.

The burn pot is cleaned via a mechanical system at pre-xed

intervals automatically by the boiler. The gure below shows the

burn pot. The company recommends to remove any ash residue

using a suction device, at least once every two days.

gure 22

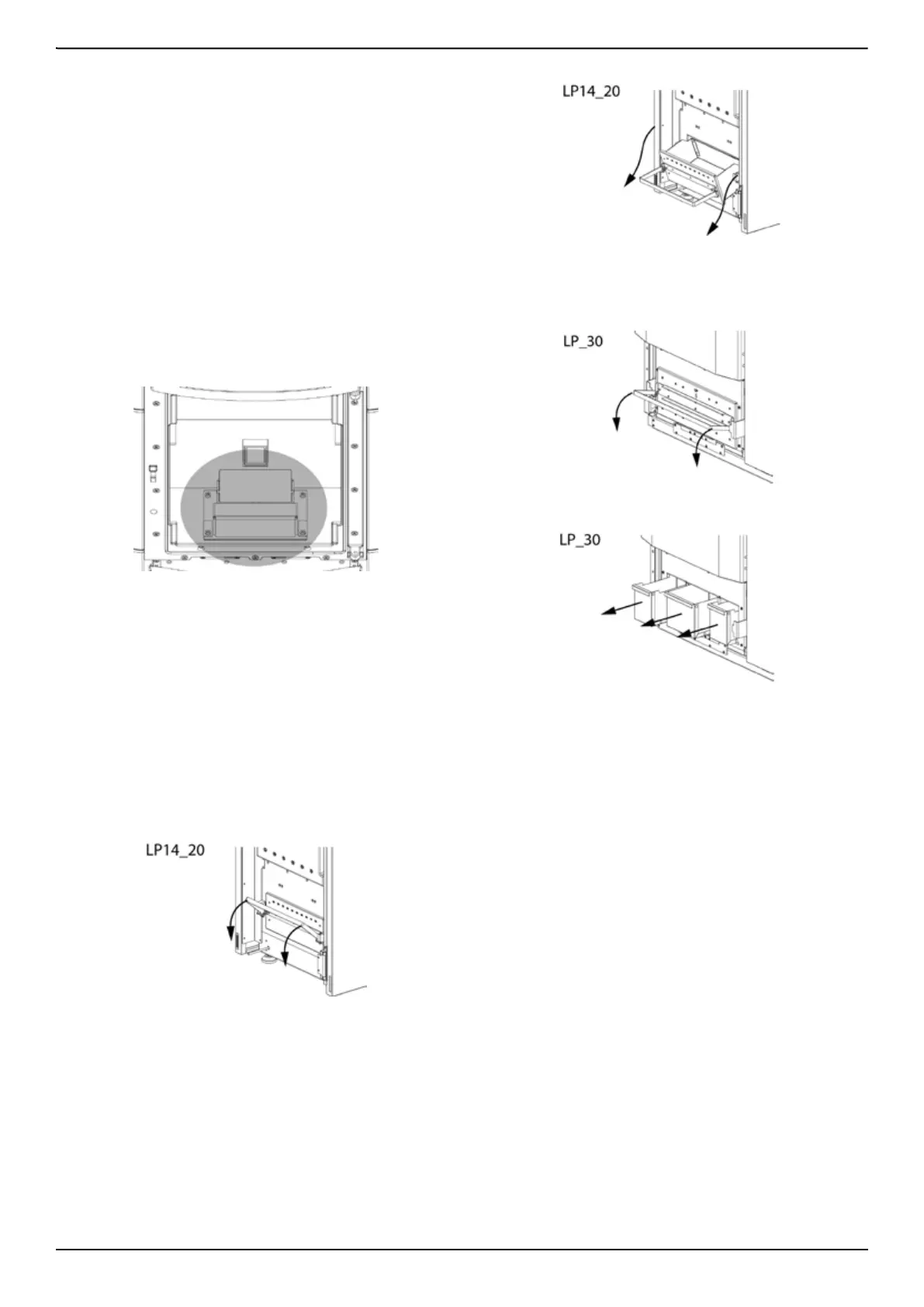

DOOR GASKET AND ASH DRAWER20.2.

The gaskets guarantee the tightness of the boiler and its consequent

good functioning.

These must be checked regularly: if they should be worn or

damaged they must be replaced immediately.

These operations must be carried out by an authorised technician.

N.B. For correct functioning, the boiler must undergo routine

maintenance by an authorised technician, at least once a year.

If the power supply cable is damaged, it must be replaced by the

after-sales service or by a similarly qualied person, so as to avoid

al risks.

gure 23

gure 24

With machine o, open the ash drawer to empty the content. The

frequency of emptying the ash drawer will be proportional to the

use of the product. Lp30 has 3 drawers.

gure 25

gure 26

CONNECTION TO THE FLUE AND 20.3.

CLEANING OF THE SAME

Suck and clean the pipe that leads to the ue yearly or anytime that

it is necessary. If there are horizontal tracts the residues must be

removed before they obstruct smoke passage. NON-CLEANING

jeopardises safety.

Maintenance operations guarantee correct functioning of the

product through time. Failure to comply with these operations can

jeopardise the safety of the product.

Loading...

Loading...