6-16

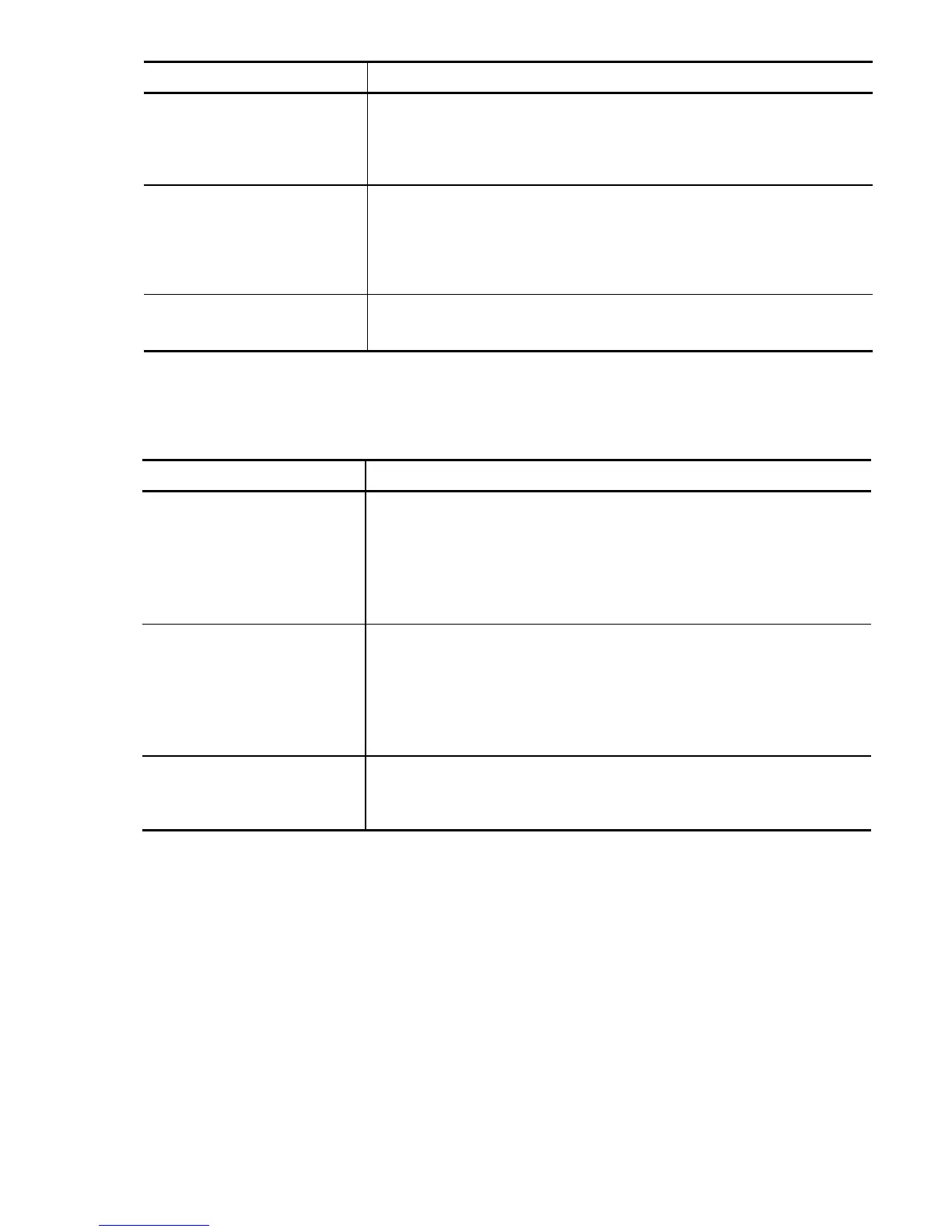

Possible Causes What to Check and Suggested Measures

(6) The value set for the

torque boost (F09 and

A05) was too high.

Check the data of function codes F09 and A05 and readjust the

data so that the motor does not stall even if you set the data to a

lower value.

Î Readjust the data of the function codes F09 and A05.

(7) The V/f pattern did not

match the motor.

Check if the base frequency (F04 and A02) and rated voltage at

base frequency (F05 and A03) match the values on the nameplate

on the motor.

Î Match the function code data to the values on the nameplate o

Braking resistor overheated

Problem The electronic thermal protection for the braking resistor has been activated.

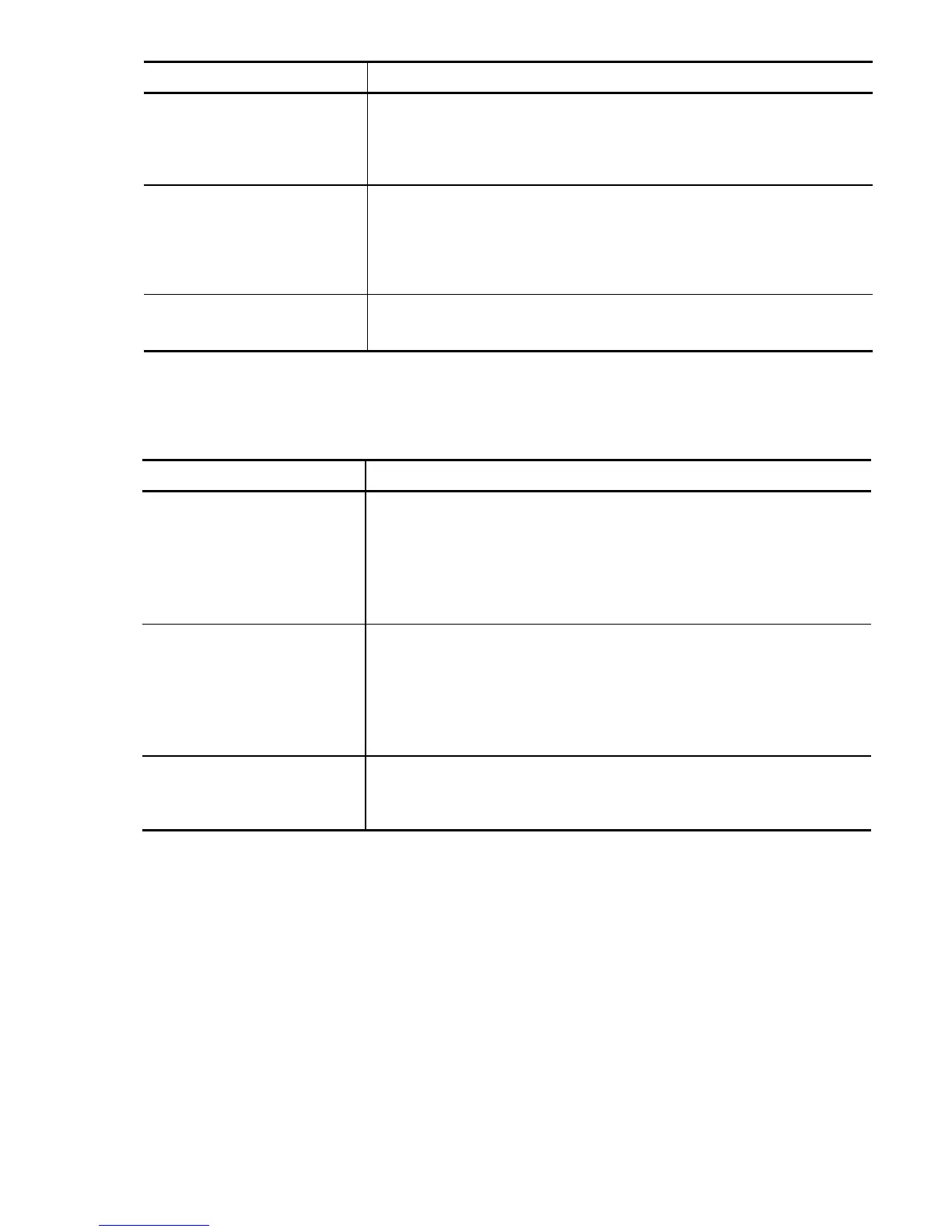

Possible Causes What to Check and Suggested Measures

(1) Braking load is too

heavy.

Reconsider the relationship between the braking load estimated

and the real load.

Î Lower the real braking load.

Î Review the performance of the current braking resistor and raise

it (Modification of related function code data (F50 and F51) is

also required.)

(2) Deceleration time

currently specified is too

short.

Re-estimate the deceleration torque and time needed for the

current load with a moment of inertia and a deceleration time.

Î Lengthen the deceleration time (F08, E11 or H56).

Î Review the performance of the braking resistor and raise it.

(Modification of related function code data (F50 and F51) is also

required.)

(3) Wrong configuration of

function codes F50 and

F51.

Recheck the specifications of the braking resistor.

Î Review data of function codes F50 and F51, then reconfigure

them.

Note: The inverter issues an overheat alarm of the braking resistor by monitoring the magnitude of

the braking load, not by measuring its surface temperature.

Therefore, even if the surface temperature of the braking resistor does not rise, when the use of the

brake exceeds more frequently than the one specified by function codes (F50 and 51), the inverter

issues an overheat alarm. To squeeze out full performance of the braking resistor, configure data of

function codes F50 and F51 while actually measuring the surface temperature of the braking

resistor.

Loading...

Loading...