7-3

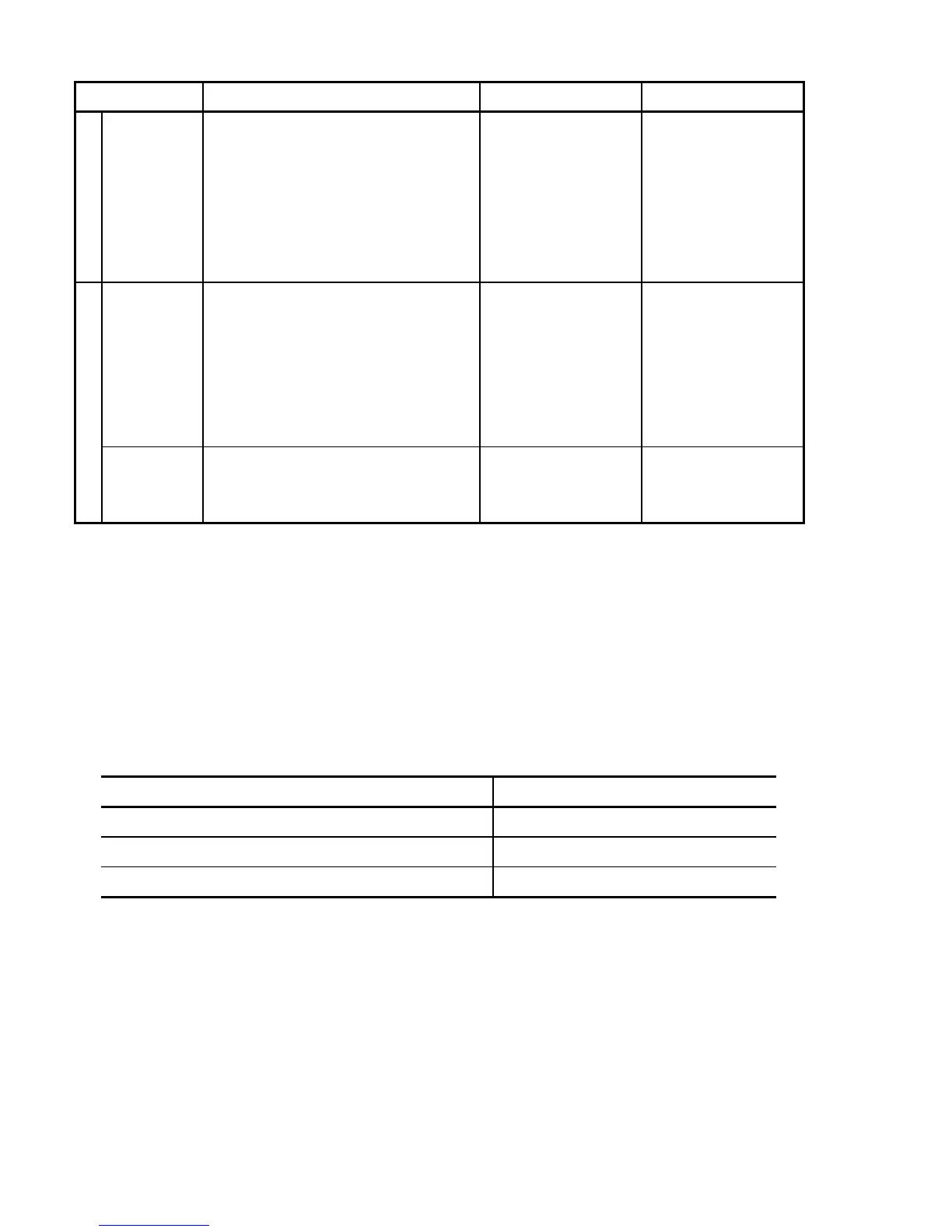

Table 7.1 List of Periodic Inspections (Continued)

Check part Check item How to inspect Evaluation criteria

Control circuit

Printed

circuit board

1) Check for loose screws and

connectors.

2) Check for odor and discoloration.

3) Check for cracks, breakage,

deformation and remarkable rust.

4) Check the capacitors for

electrolyte leaks and

deformation.

1) Retighten.

2) Smelling and

visual inspection

3), 4)

Visual inspection

1), 2), 3), 4)

No abnormalities

Cooling fan

1) Check for abnormal noise and

excessive vibration.

2) Check for loose bolts.

3) Check for discoloration caused by

overheat.

1) Hearing and

visual inspection,

or turn manually

(be sure to turn

the power OFF).

2) Retighten.

3) Visual inspection

1) Smooth rotation

2), 3)

No abnormalities

Cooling system

Ventilation

path

Check the heat sink, intake and

exhaust ports for clogging and

foreign materials.

Visual inspection No abnormalities

If the inverter is stained, wipe it off with a chemically neutral cloth to remove dust and use a vacuum

cleaner.

7.3 List of Periodical Replacement Parts

Each part of the product has its own service life that will vary according to the environmental and

operating conditions. It is recommended that the following parts be replaced as specified below.

When the replacement is necessary, consult your Fuji Electric representative.

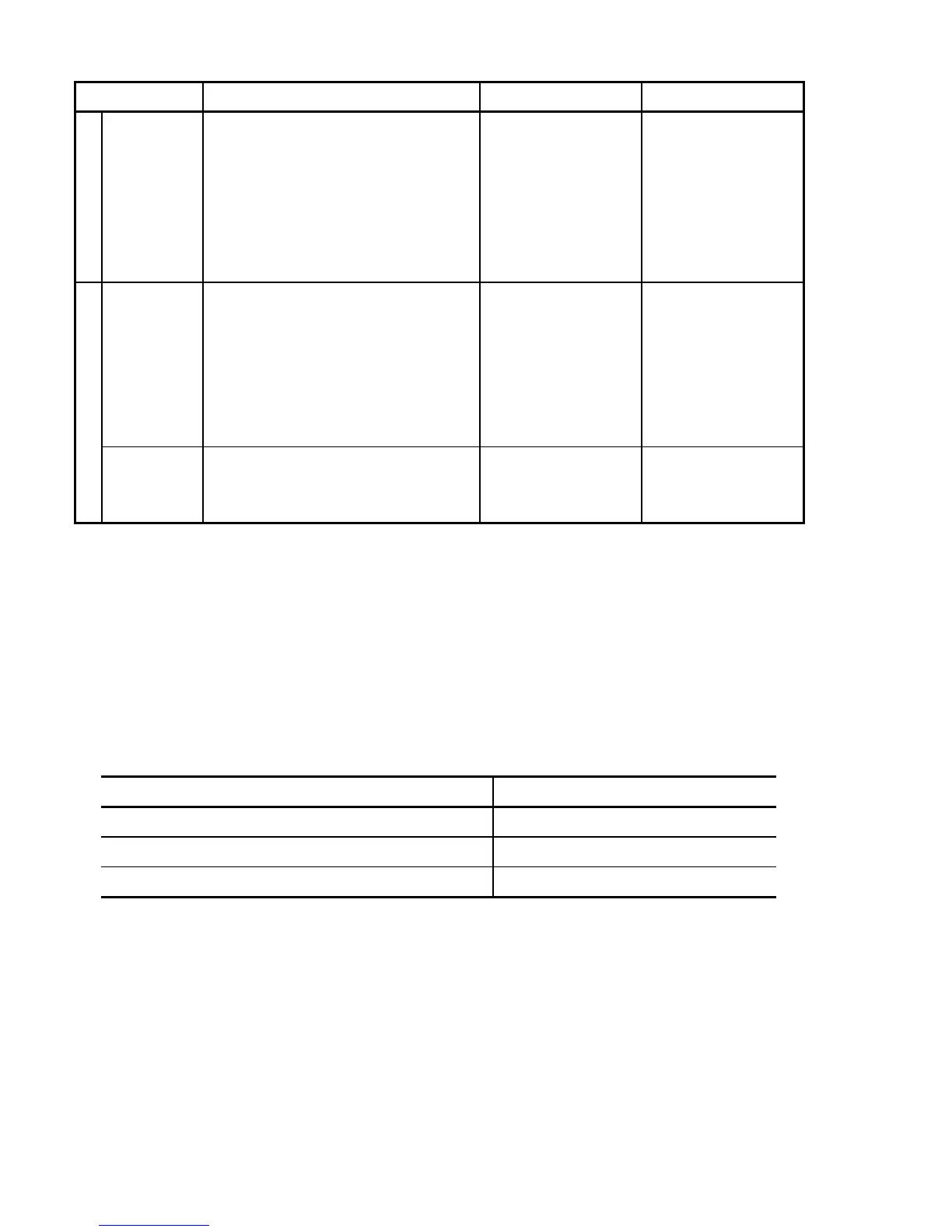

Table 7.2 Replacement Parts

Part name Standard replacement intervals

DC link bus capacitor 10 years

Electrolytic capacitors on the printed circuit boards 10 years

Cooling fan 10 years

(Note) These replacement intervals are based on the estimated service life of the inverter at an ambient

temperature of 40qC (104qF) under 80% of full load. In environments with an ambient temperature

above 40qC (104qF) or a large amount of dust or dirt, the replacement intervals may need to be

reduced.

Standard replacement intervals mentioned above is only a guide for replacement, not a guaranteed

service life.

Loading...

Loading...