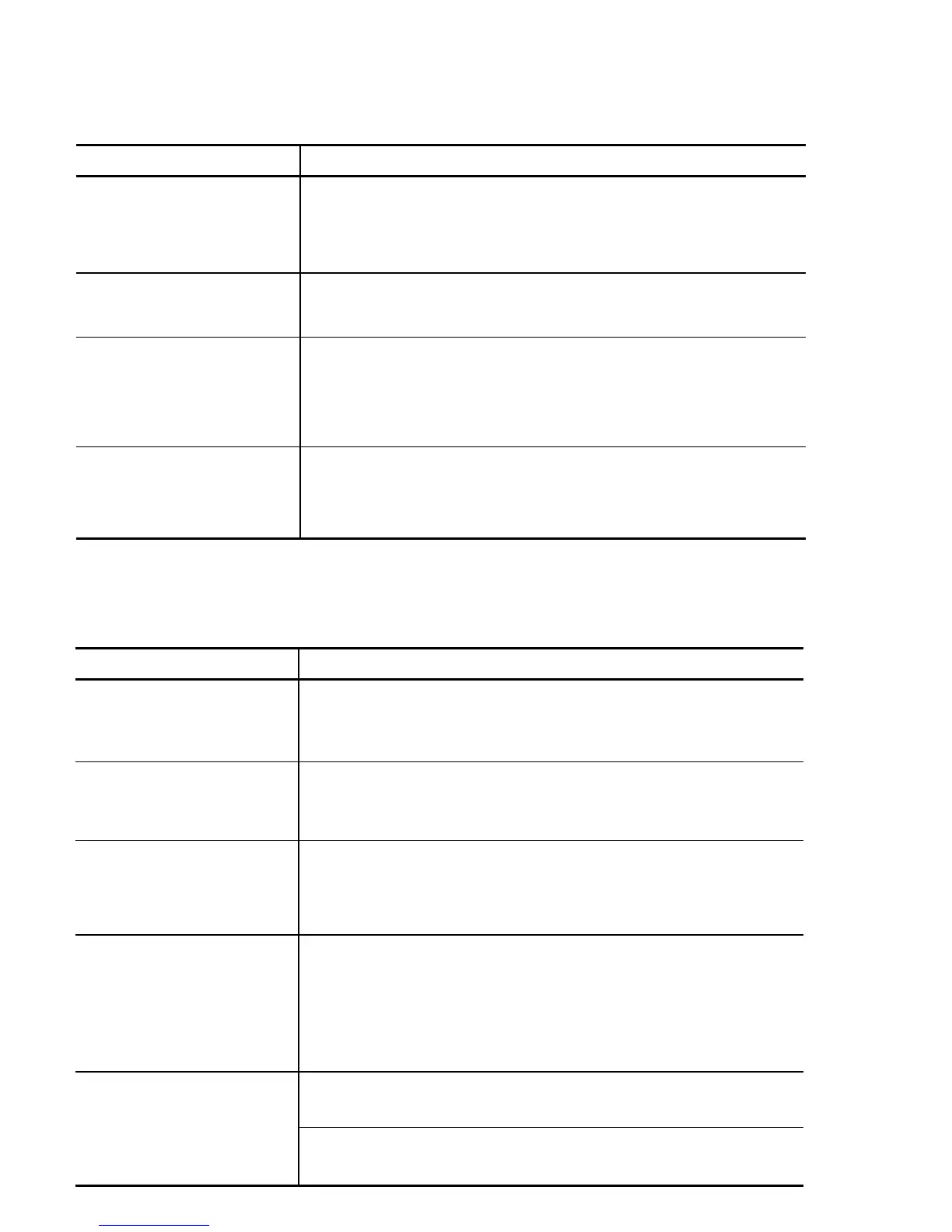

Electronic thermal overload alarm 2

Problem Electronic thermal protection for motor 1 or motor 2 activated.

Possible Causes What to Check and Suggested Measures

(1) The characteristics of

electronic thermal did

not match those of the

motor overload.

Check the motor characteristics.

Î Reconsider the data of function codes (P99, F10 and F12) and

(A39, A06 and A08).

Î Use an external thermal relay.

(2) Activation level for the

electronic thermal relay

was inadequate.

Check the continuous allowable current of the motor.

Î Reconsider and change the data of function codes F11 and A07.

(3) The acceleration/

deceleration time was

too short.

Check that the motor generates enough torque for acceleration

deceleration. This torque is calculated from the moment of inertia

for the load and the acceleration/ deceleration time.

Î Increase the acceleration/ deceleration time (F07, F08, E10,

E11, and H56).

(4) Load was too heavy. Measure the output current.

Î Lighten the load (e.g., lighten the load before overload occurs

using E34 (Overload Early Warning). (In winter, the load tends to

increase.)

[ 11 ]

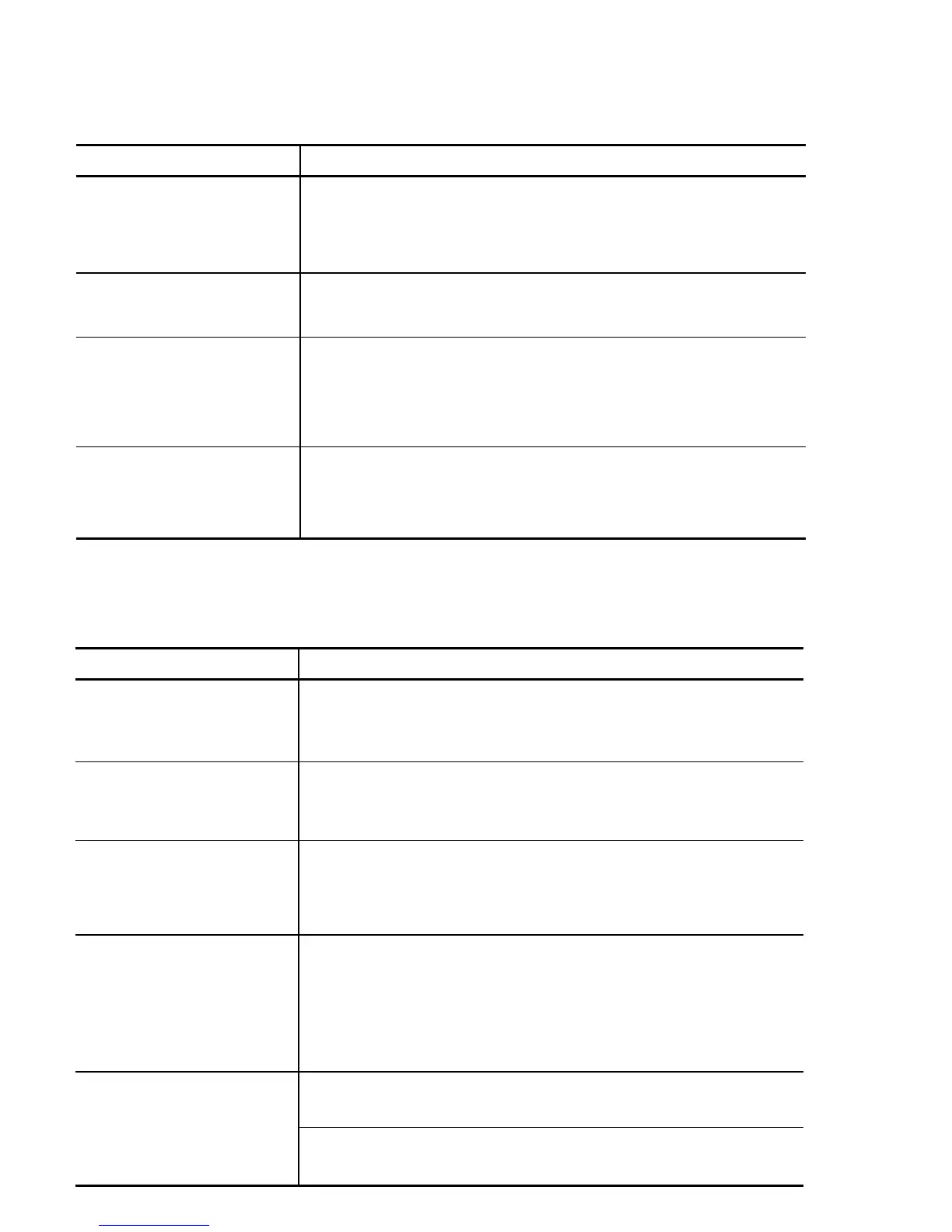

Overload

Problem Temperature inside inverter rose abnormally.

Possible Causes What to Check and Suggested Measures

(1) Temperature around the

inverter exceeded that

of inverter

specifications.

Measure the temperature around the inverter.

Î Lower the temperature (e.g., ventilate the panel well).

(2) The torque boost setting

(F09 and A05) was too

high.

Check the setting of F09 and A05 (Torque Boost) and make sure

that lowering it would not cause the motor to stall.

Î Adjust the setting of F09 and A05.

(3) The acceleration/

deceleration time was

too short.

Recalculate the required acceleration/deceleration torque and time

from the moment of inertia for the load and the deceleration time.

Î Increase the acceleration/deceleration time (F07, F08, E10, E11,

and H56).

(4) Load was too heavy. Measure the output current.

Î Lighten the load (e.g., lighten the load before overload occurs

using the overload early warning (E34)). (In winter, the load

tends to increase.)

Î Decrease the motor sound (carrier frequency) (F26).

Î Enable overload prevention control (H70).

Check if there is sufficient clearance around the inverter.

Î Increase the clearance.

(5) Air vent is blocked.

Check if the heat sink is not clogged.

ÎClean the heat sink.

Loading...

Loading...