5-156 F60 Feeder Protection System GE Multilin

5.5 FLEXLOGIC 5 SETTINGS

5

5.5.2 FLEXLOGIC RULES

When forming a FlexLogic equation, the sequence in the linear array of parameters must follow these general rules:

1. Operands must precede the operator which uses the operands as inputs.

2. Operators have only one output. The output of an operator must be used to create a virtual output if it is to be used as

an input to two or more operators.

3. Assigning the output of an operator to a virtual output terminates the equation.

4. A timer operator (for example, "TIMER 1") or virtual output assignment (for example, " = Virt Op 1") may only be used

once. If this rule is broken, a syntax error will be declared.

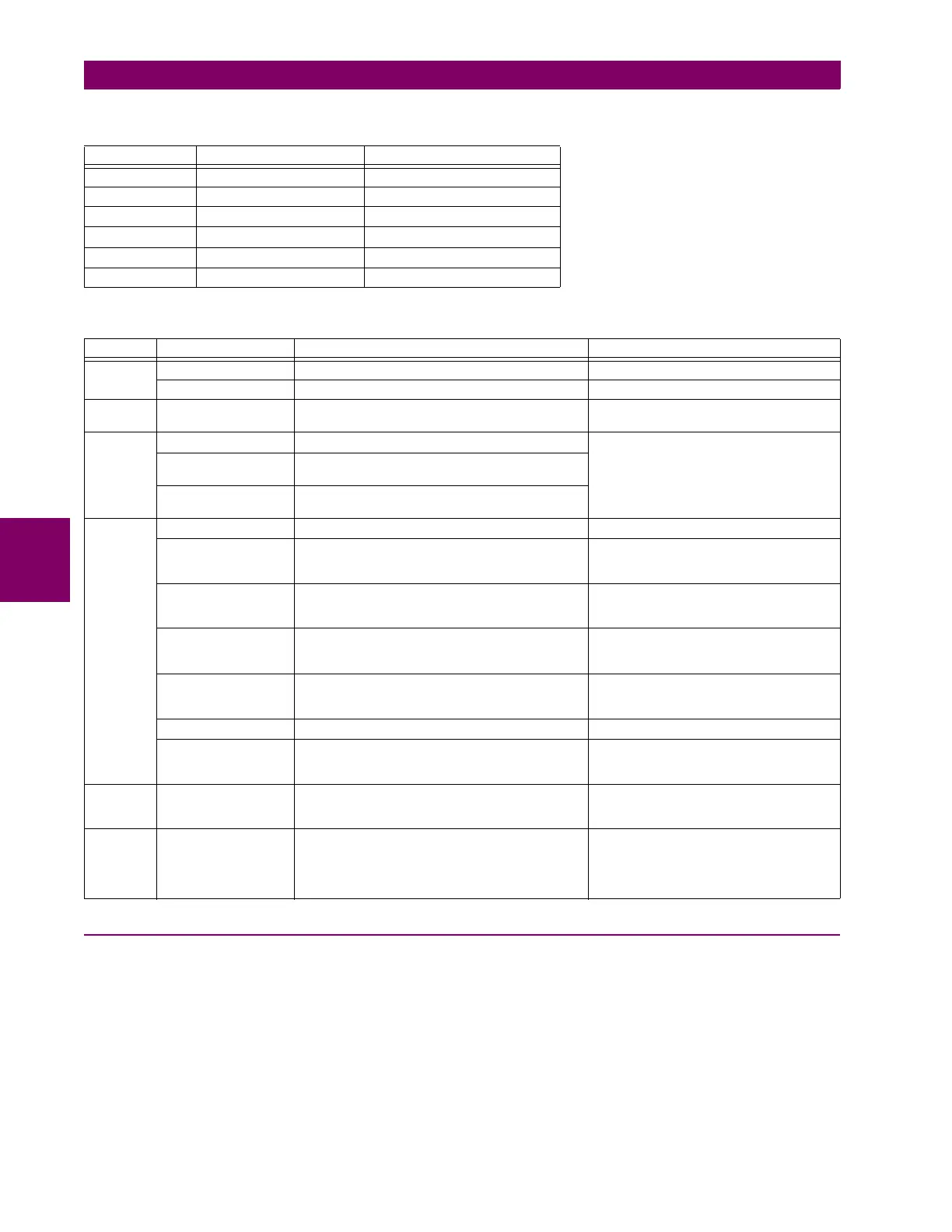

Table 5–19: FLEXLOGIC GATE CHARACTERISTICS

GATES NUMBER OF INPUTS OUTPUT IS ‘1’ (= ON) IF...

NOT 1 input is ‘0’

OR 2 to 16 any input is ‘1’

AND 2 to 16 all inputs are ‘1’

NOR 2 to 16 all inputs are ‘0’

NAND 2 to 16 any input is ‘0’

XOR 2 only one input is ‘1’

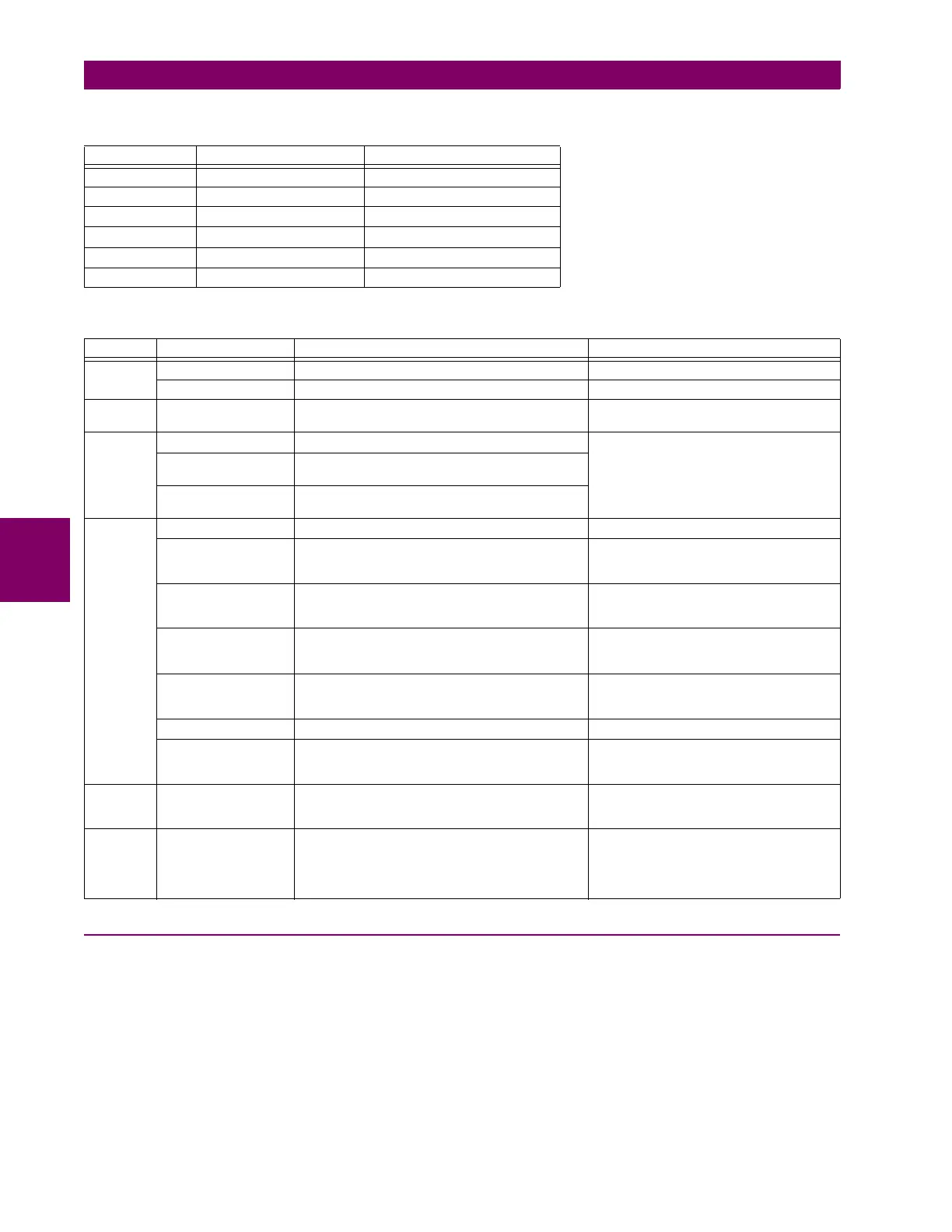

Table 5–20: FLEXLOGIC OPERATORS

TYPE SYNTAX DESCRIPTION NOTES

Editor INSERT Insert a parameter in an equation list.

DELETE Delete a parameter from an equation list.

End END The first END encountered signifies the last entry in

the list of processed FlexLogic parameters.

One-shot POSITIVE ONE SHOT One shot that responds to a positive going edge. A ‘one shot’ refers to a single input gate

that generates a pulse in response to an

edge on the input. The output from a ‘one

shot’ is True (positive) for only one pass

through the FlexLogic equation. There is a

maximum of 64 ‘one shots’.

NEGATIVE ONE

SHOT

One shot that responds to a negative going edge.

DUAL ONE SHOT One shot that responds to both the positive and

negative going edges.

Logic

gate

NOT Logical NOT Operates on the previous parameter.

OR(2)

↓

OR(16)

2 input OR gate

↓

16 input OR gate

Operates on the 2 previous parameters.

↓

Operates on the 16 previous parameters.

AND(2)

↓

AND(16)

2 input AND gate

↓

16 input AND gate

Operates on the 2 previous parameters.

↓

Operates on the 16 previous parameters.

NOR(2)

↓

NOR(16)

2 input NOR gate

↓

16 input NOR gate

Operates on the 2 previous parameters.

↓

Operates on the 16 previous parameters.

NAND(2)

↓

NAND(16)

2 input NAND gate

↓

16 input NAND gate

Operates on the 2 previous parameters.

↓

Operates on the 16 previous parameters.

XOR(2) 2 input Exclusive OR gate Operates on the 2 previous parameters.

LATCH (S,R) Latch (set, reset): reset-dominant The parameter preceding LATCH(S,R) is

the reset input. The parameter preceding

the reset input is the set input.

Timer TIMER 1

↓

TIMER 32

Timer set with FlexLogic timer 1 settings.

↓

Timer set with FlexLogic timer 32 settings.

The timer is started by the preceding

parameter. The output of the timer is

TIMER #.

Assign

virtual

output

= Virt Op 1

↓

= Virt Op 96

Assigns previous FlexLogic operand to virtual

output 1.

↓

Assigns previous FlexLogic operand to virtual

output 96.

The virtual output is set by the preceding

parameter

Loading...

Loading...