Influence of Proportional, Derivative and Integral actions on response of process under control

* An increase in P.B. reduces oscillations but increases deviation.

* A reduction in P.B. reduces the deviation but provokes oscillations of the controlled variable (the system tends to be

unstable if P.B. value is too low).

* An increase in Derivative Action corresponds to an increase in Derivative Time, reduces deviation and prevents

oscillation up to a critical value of Derivative Time, beyond which deviation increases and prolonged oscillations occur.

* An increase in Integral Action corresponds to a reduction in Integral Time, and tends to eliminate deviation between

the controlled variable and the setpoint when the system is running at rated speed.

If the Integral Time value is too long (Weak integral action), deviation between the controlled variable and the setpoint

may persist.

Contact GEFRAN for more information on control actions.

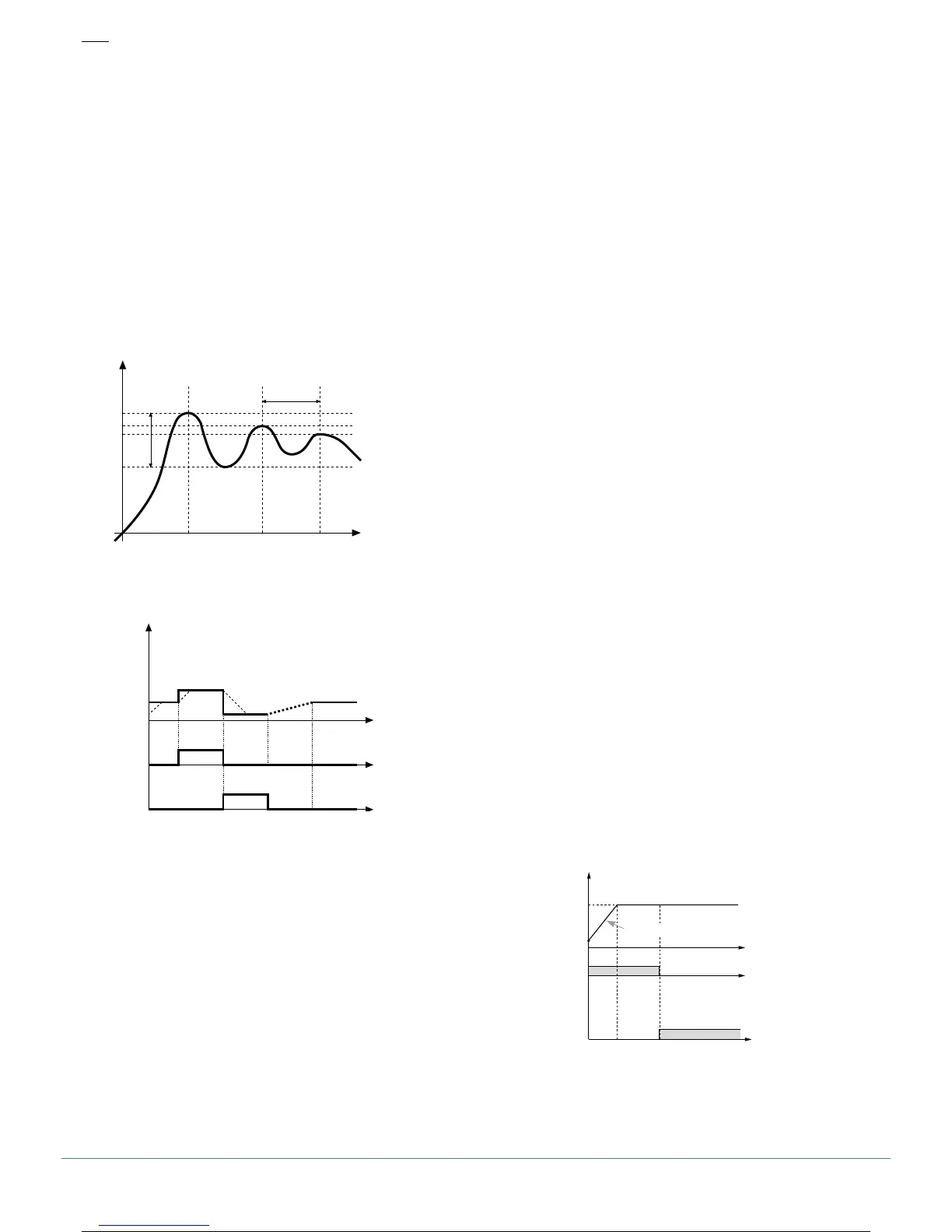

Manual Tuning

A) Enter the setpoint at its working value.

B) Set the proportional band at 0.1% (with on-off type setting).

C) Switch to automatic and observe the behavior of the variable. It will be similar to that in the figure:

D) The PID parameters are calculated s follows: Proportional band

Peak

P.B.= ---------------------------------------- x 100

V max - V min

(V max - V min) is the scale range.

Integral time: It = 1.5 x T

Derivative time: dt = It/4

E) Switch the unit to manual, set the calculated parameters. Return to

PID action by setting the appropriate relay output cycle time, and switch

back to Automatic.

F) If possible, to optimize parameters, change the setpoint and check

temporary response. If an oscillation persists, increase the proportional

band. If the response is too slow, reduce it.

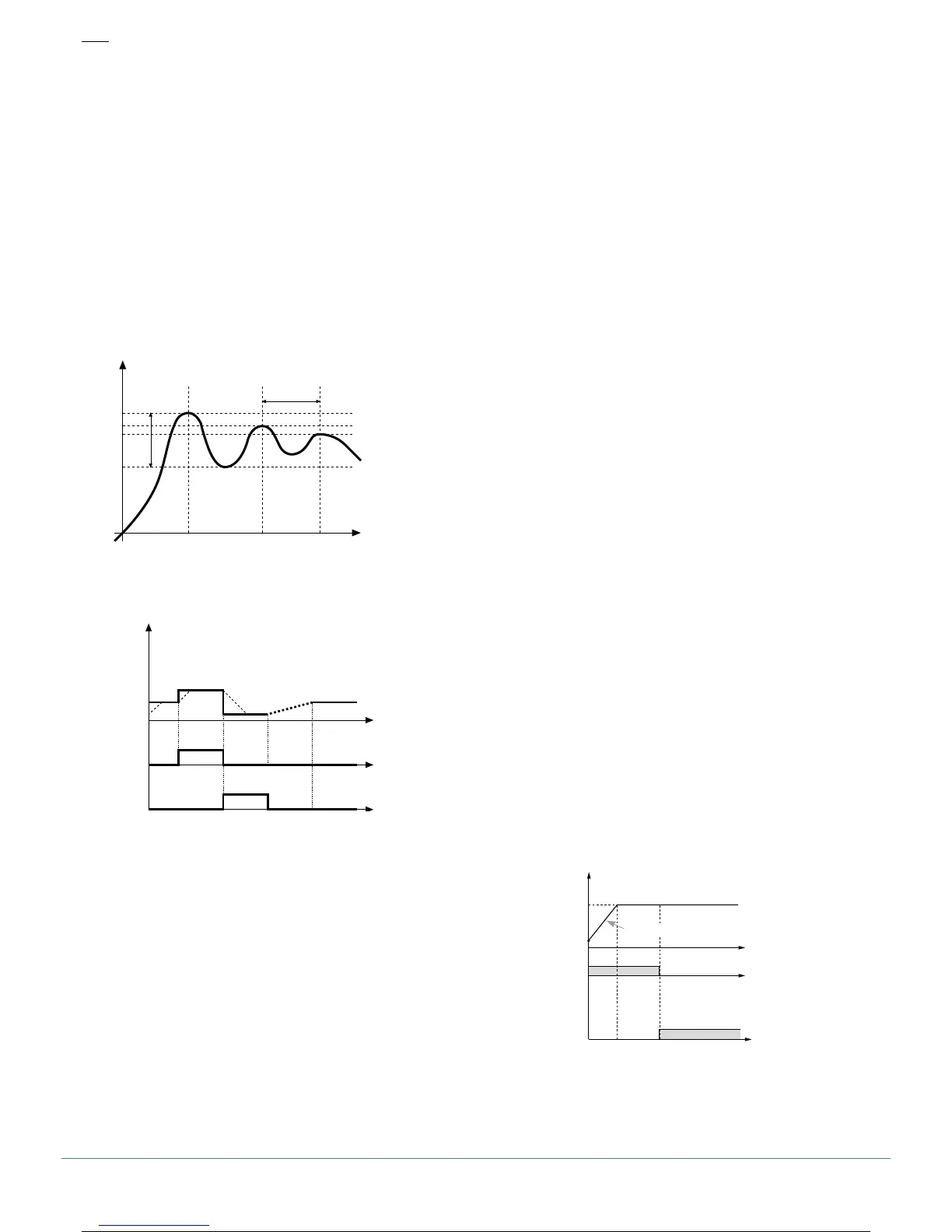

Multiset function, Set gradient

The multiset function is enabled in hd.1.

The gradient function is always enabled.

You can select between setpoint 1 and setpoint 2 with the faceplate key

or with digital input.

You can display the setpoint 1-2 selection by means of LED.

SET GRADIENT: if set to ≠0, the setpoint is assumed equal to PV at

power-on and auto/man switchover. With gradient set, it reaches the local

setpoint or the one selected.

Every variation in setpoint is subject to a gradient.

The set gradient is inhibited at power-on when self-tuning is engaged.

Ifthesetgradientissetto≠0,itisactiveevenwithvariationsofthelocal

setpoint, settable only on the relative SP menu.

The control setpoint reaches the set value at the speed defined by the

gradient.

Process

Variable

Time

T

Peak

SP1

SP2

SPrem

SP1

(*)

ON

ON

SP

IN1

LOC/REM

t

t

t

(*) if the set gradient is set

Twin setpoint application

(ramp + hold + time expiration alarm)

AL

Referred to current

setpoint

Setpoint profile

Setpoint < AL

Delay for trip-

ping

(*)

Absolute alarm

Reverse alarm

(*) Time set in

parameter Hy.n

Direct alarm

Time (min. or sec.)

4980291G_MHW_2500_08-2010_ENG

49 / 77

Loading...

Loading...