EXAMPLES OF CUSTOM LINEARIZATION

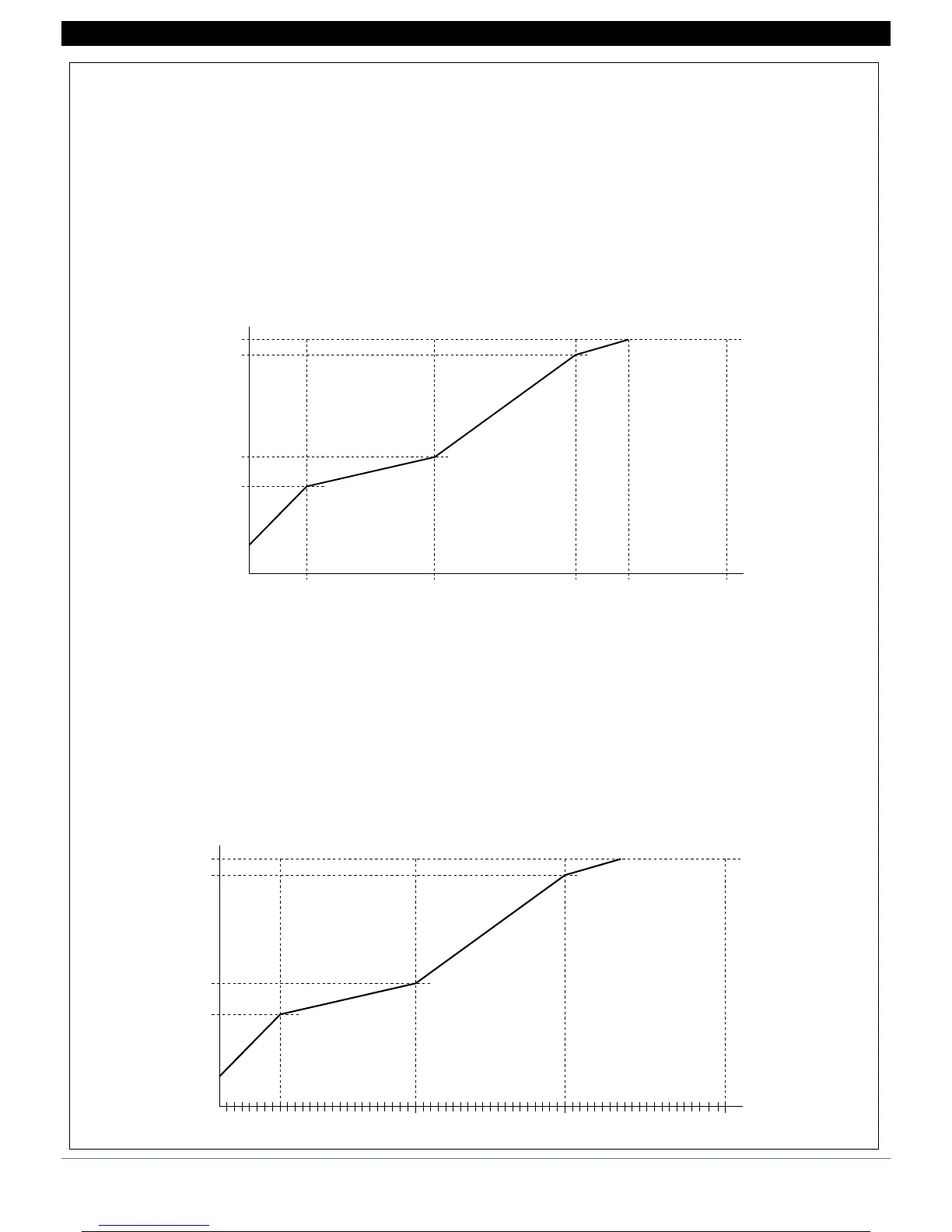

Example of custom linearization: type 0

(at variable amplitude intervals, max. 32)

For positive polarization signals (ex. 0...50mV) S.00 is the value displayed for minimum input (ex. 0mV);

if 32 intervals are set, S.32b is the value displayed for input = S.32A * (f.s. / 10000)

(ex. if S.32A = 10000, S.32b is the value displayed with input = 50mV)

For symmetrical polarization signals (ex. -25mV...+25mV) S.00 is the value displayed for minimum input (ex. -25mV);

if 32 intervals are set, S.32b is the value displayed for input = S.32A * (f.s. / 10000)

(ex. if S.32A = 10000, S.32b is the value displayed with input = +25mV)

In case of linearization type 1, ... ,4 S.nnA values are acquired directly by its input IN1, ... ,IN4

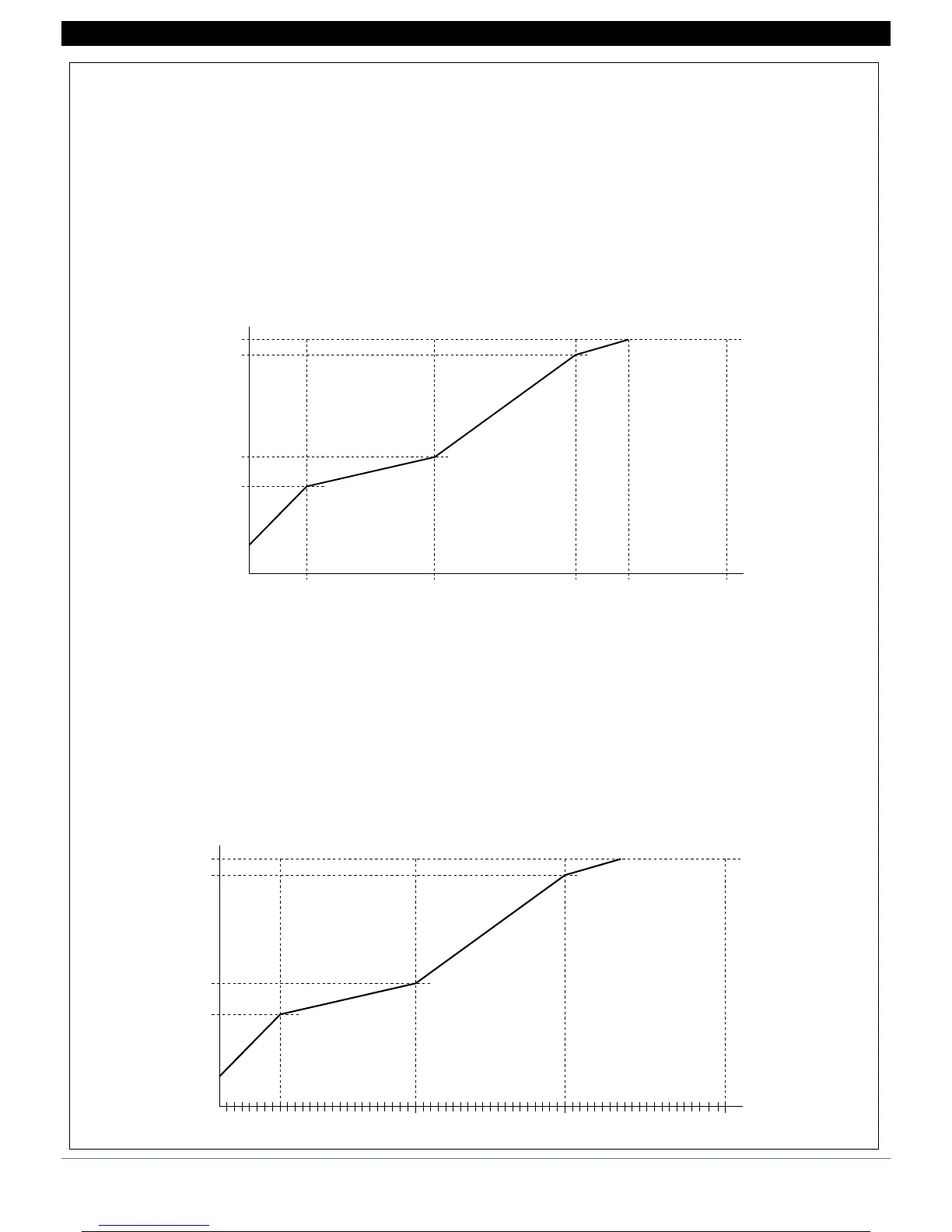

Example of custom linearization: type 5

(at 64 constant amplitude intervals = f.s. / 64)

For positive polarization signals (ex. 0...50mV) S.00 is the value displayed for minimum input (ex. 0mV);

S.64 is the value displayed for maximum input (es 50mV)

For positive polarization signals (ex. -25mV...+25mV) S.00 is the value displayed for minimum input (ex. -25mV);

S.64 is the value displayed for maximum input (ex. +25mV)

0

S.01A

Loading...

Loading...