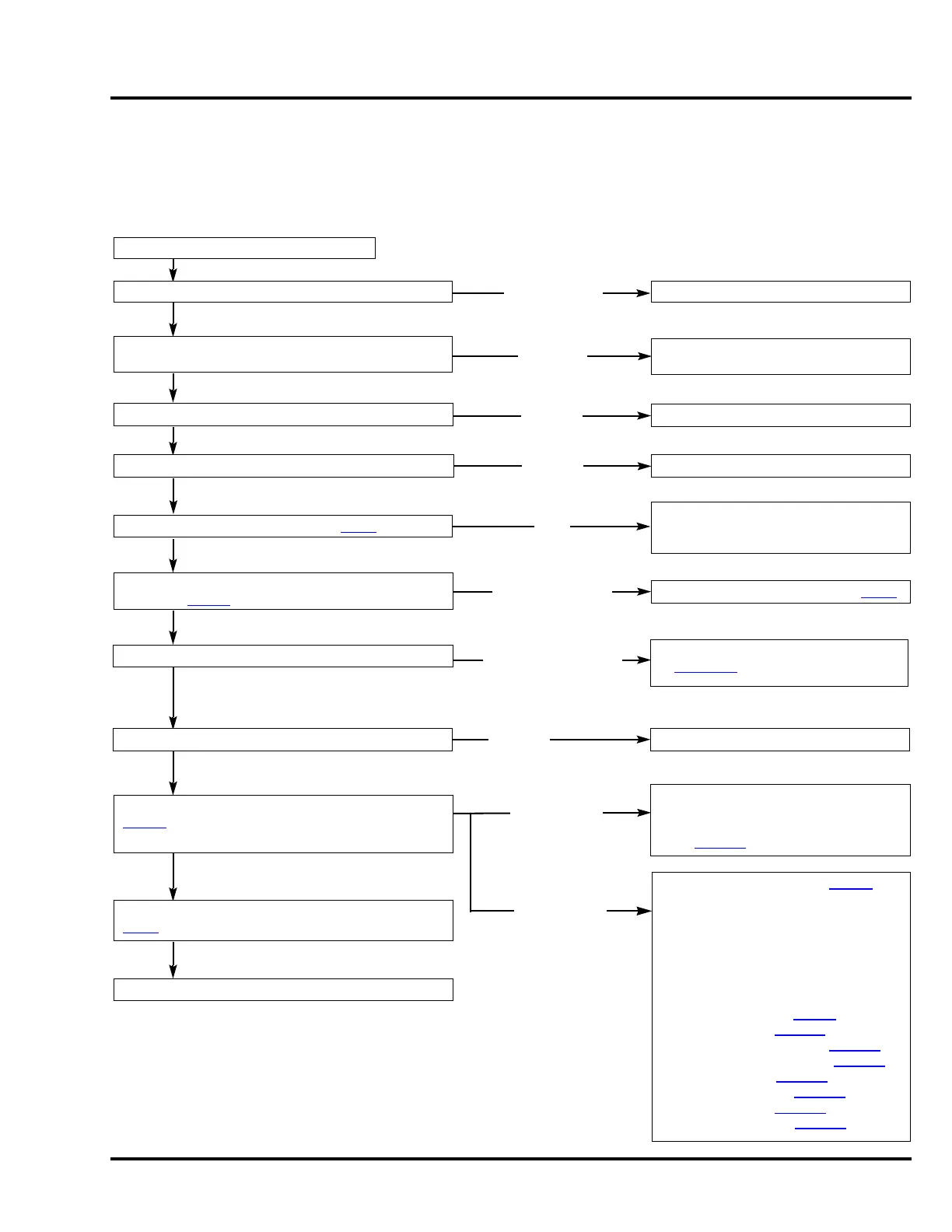

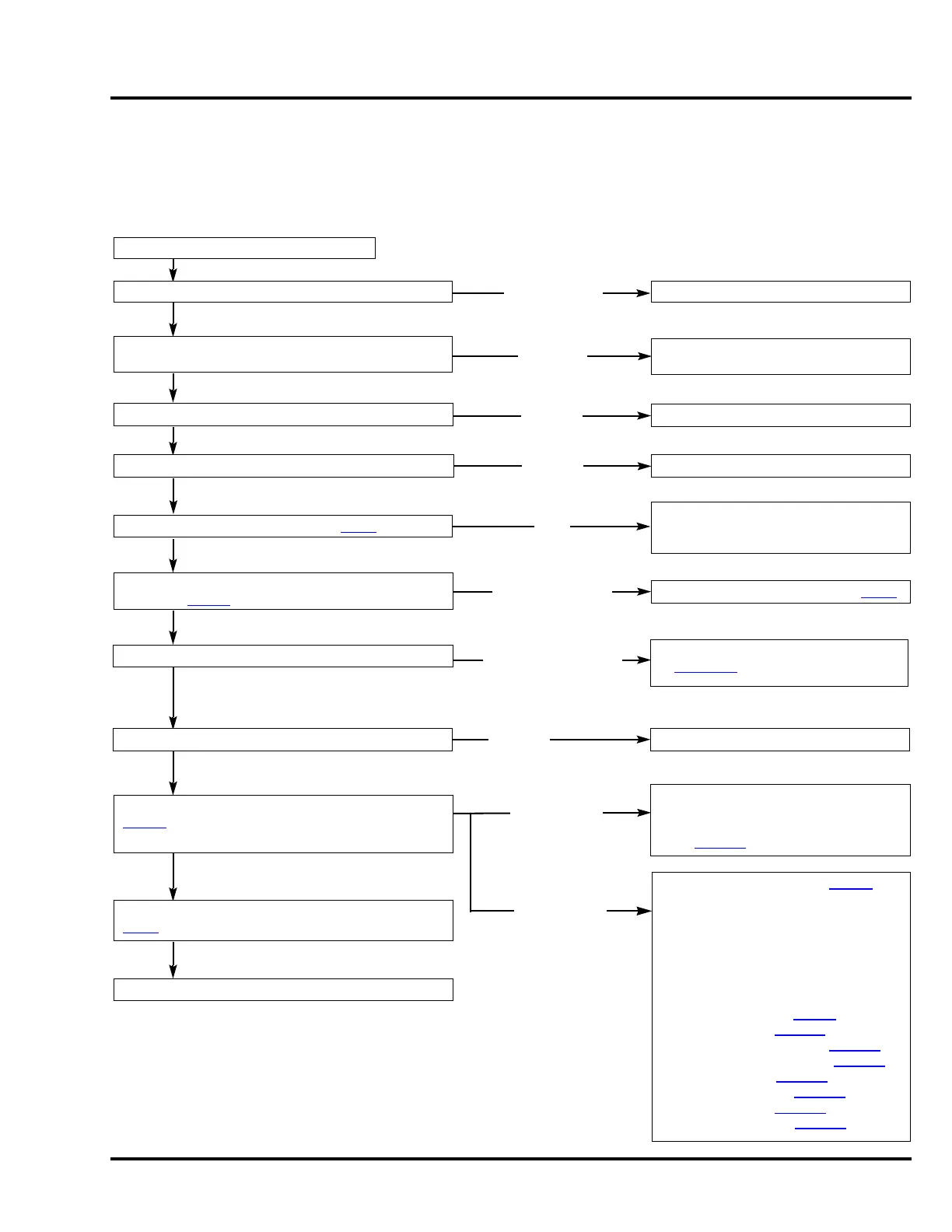

7. TROUBLESHOOTING

Sufficient fuel in tank

Refuel.

• Install a new spark plug, then restart

the engine.

• Check the carburetor for flooding.

• Check the ignition coil air gap (P. 9 -6 ).

Check the valve clearance (P. 3-15),

and then perform the cylinder

compression test. If the cylinder

compression is still too low, perform a

leak down test.

If the air leak down test shows air

leakage, check the following as

determined by the test:

- Valve sticking open (P. 3 -1 5

)

- Valve seat width (P. 1 0- 3 1

)

- Carbon on the valve seat (P. 10-31

)

- Piston ring side clearance (P. 10-25

)

- Piston ring width (P. 1 0 - 25

)

- Piston ring end gap (P. 1 0- 2 5

)

- Piston skirt O.D. (P. 10-24

)

- Cylinder sleeve I.D. (P. 1 0-24

)

Install the spark plug and restart the engine.

No fuel in tank

Dry

Wet

Remove the spark plug and inspect (P. 3- 8 ).

Good spark

No or weak spark

Install a compression gauge in the spark plug hole

(P. 2- 13

) and briskly crank the engine repeatedly until

a stabilized reading is obtained.

Install the spark plug in the plug cap and perform the

spark test (P. 2- 1 3

).

Remove, disassemble, and clean the carburetor

(P. 8- 5

).

Check the choke butterfly with the engine cold.

Choke closed

Confirm the fuel quality. If gasoline is more than 30

days old, the engine may be hard to start.

Fresh fuel

Drain the fuel system, and refill with

fresh gasoline.

Stale fuel

See “CHOKE CONTROL SYSTEM”

on page 2-15

.

Make sure the fuel valve is ON.

Clean or replace the air filter.

Clean

Clogged

Check the air filter.

Choke partially open

Compression normal

Clean or replace the fuel strainer.

Clean

Clogged

Check the fuel strainer.

Clean or replace the spark arrester.

Clean

Clogged

Check the spark arrester (if equipped).

Compression

is above

80 psi

Camshaft decompressor is not working,

valve clearance excessive, or damaged

rocker arm. Inspect the decompressor

(page P. 10-23

).

Compression

is too low

Check the fuel level.

Loading...

Loading...