Loading...

Loading...

Do you have a question about the Hypertherm Powermax105 and is the answer not in the manual?

| Brand | Hypertherm |

|---|---|

| Model | Powermax105 |

| Category | Welding System |

| Language | English |

Details on Hypertherm's product warranty periods and conditions.

Overview of the Powermax105 plasma cutting system and its capabilities.

Technical specifications and ratings of the Powermax105 power supply.

Detailed specifications for cutting capacity, speed, and gouging.

Instructions for ensuring appropriate electrical power for the system.

Essential information on proper grounding for safety and performance.

Details on electrical requirements and fuse recommendations for different models.

Steps for preparing the gas supply, including quality and filtration.

Overview of the power supply's controls, LEDs, and status screen.

Details on the adjustment knob, selectors, and indicator LEDs on the front.

Explanation of the system status and fault information displayed on the screen.

Understanding fault codes displayed on the status screen.

Visual indicators for system faults and warnings.

Step-by-step guide to operating the Powermax system for cutting.

Procedures for connecting essential power, gas, and torch leads.

How to properly connect the work lead to the power supply.

Correct method for attaching the work clamp to the workpiece.

Procedure for manually setting gas pressure for specific applications.

How to adjust the cutting current using the adjustment knob.

Information on duty cycle and its impact on system operation.

Guidance on selecting appropriate consumables for different cutting tasks.

List of consumables for drag-cutting, gouging, FineCut, and HyAccess.

Step-by-step instructions for installing consumables on the torch.

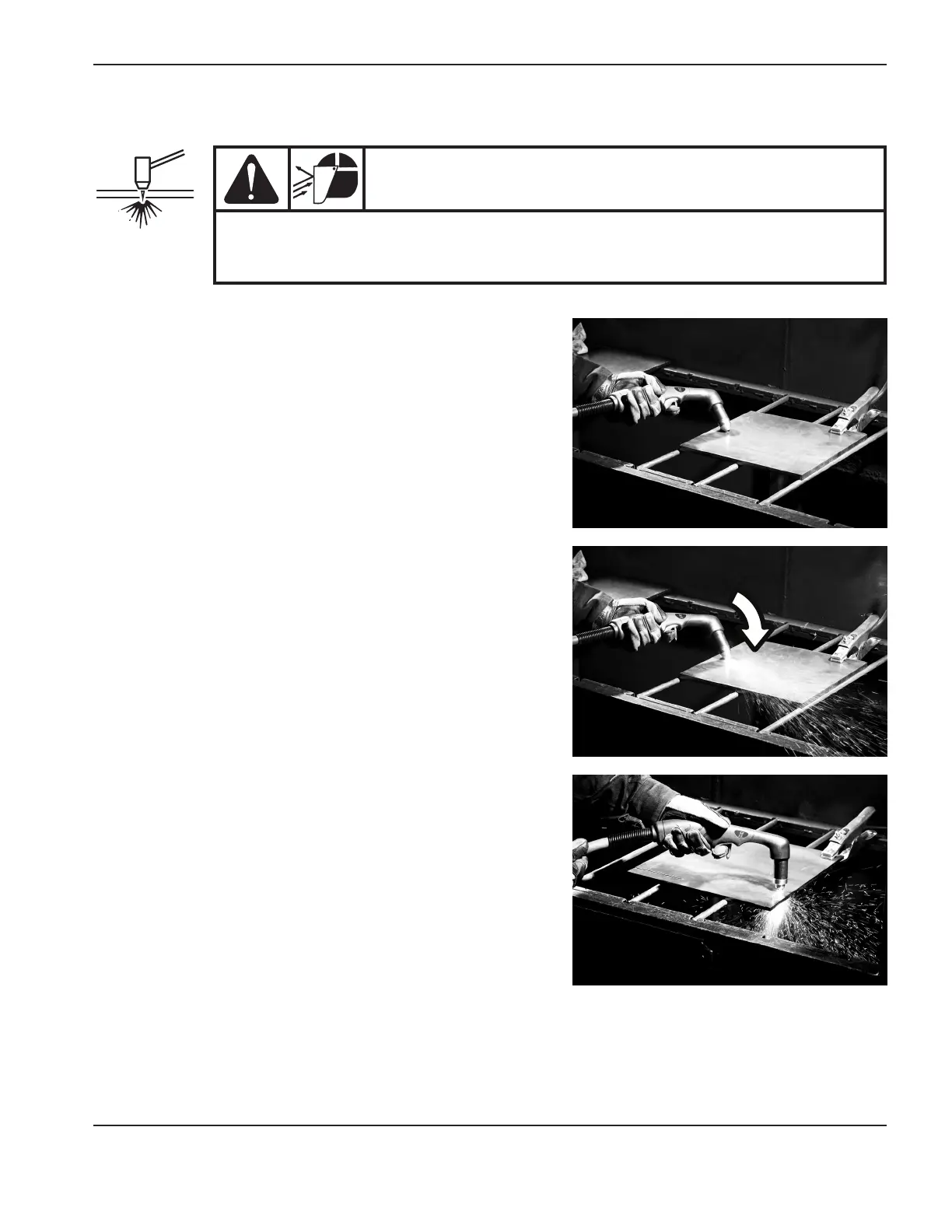

Basic safety and operational guidance for using the hand torch.

Tips and techniques for achieving optimal hand cutting results.

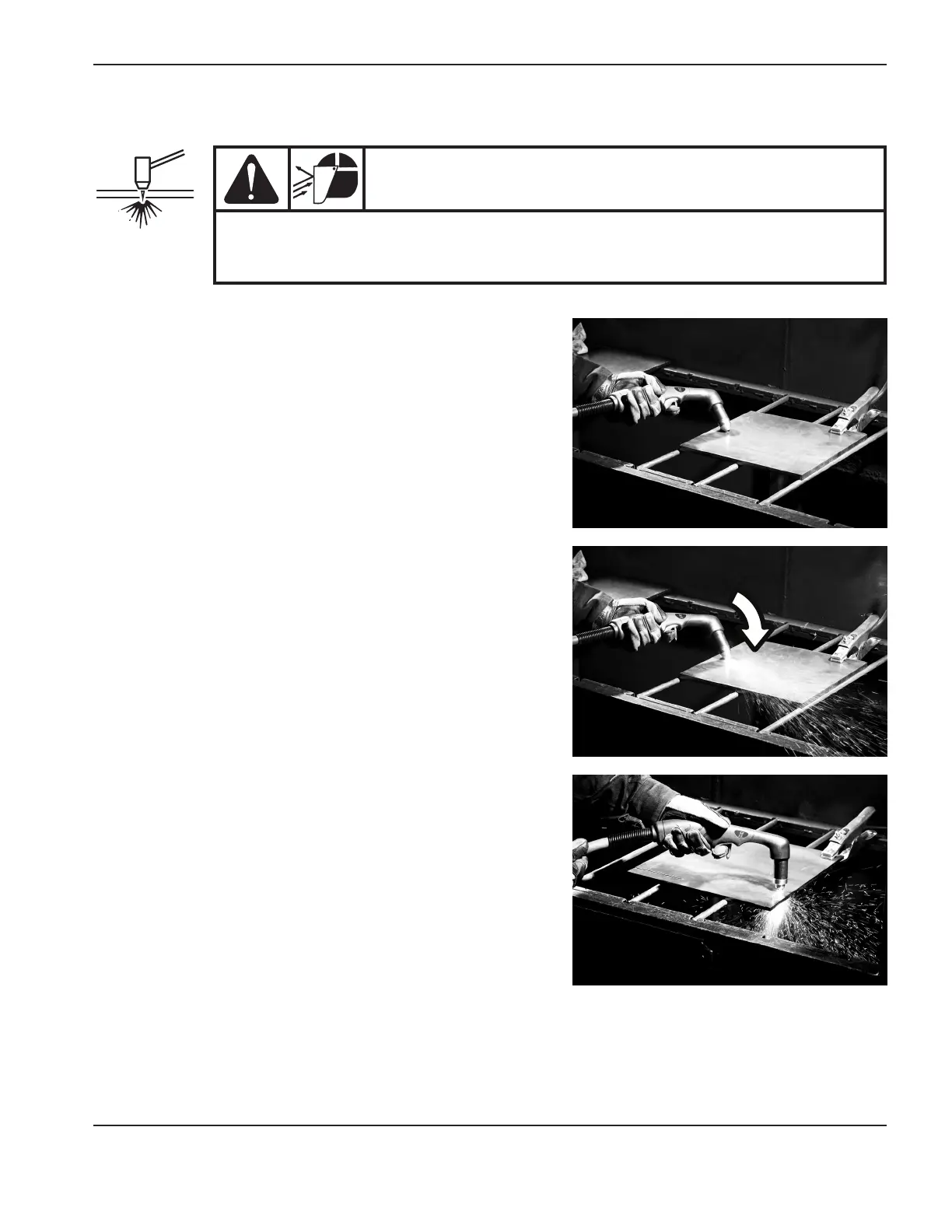

Procedure for piercing material before starting a cut.

Technique for performing gouging operations with the hand torch.

How to interpret and use cut charts for optimized mechanized cutting.

Factors affecting cut quality and methods for optimization.

Troubleshooting common problems encountered in mechanized cutting.

Schedule and procedures for regular system maintenance.

Common problems and their solutions for the Powermax system.

Detailed explanations of fault codes and corrective actions.