C83

1-25

C43C53

1-241-23

1

4

7

9

5

5

6

7

8

3

2

S

A

12 - IE

INSTALLERUSERTECHNICIAN

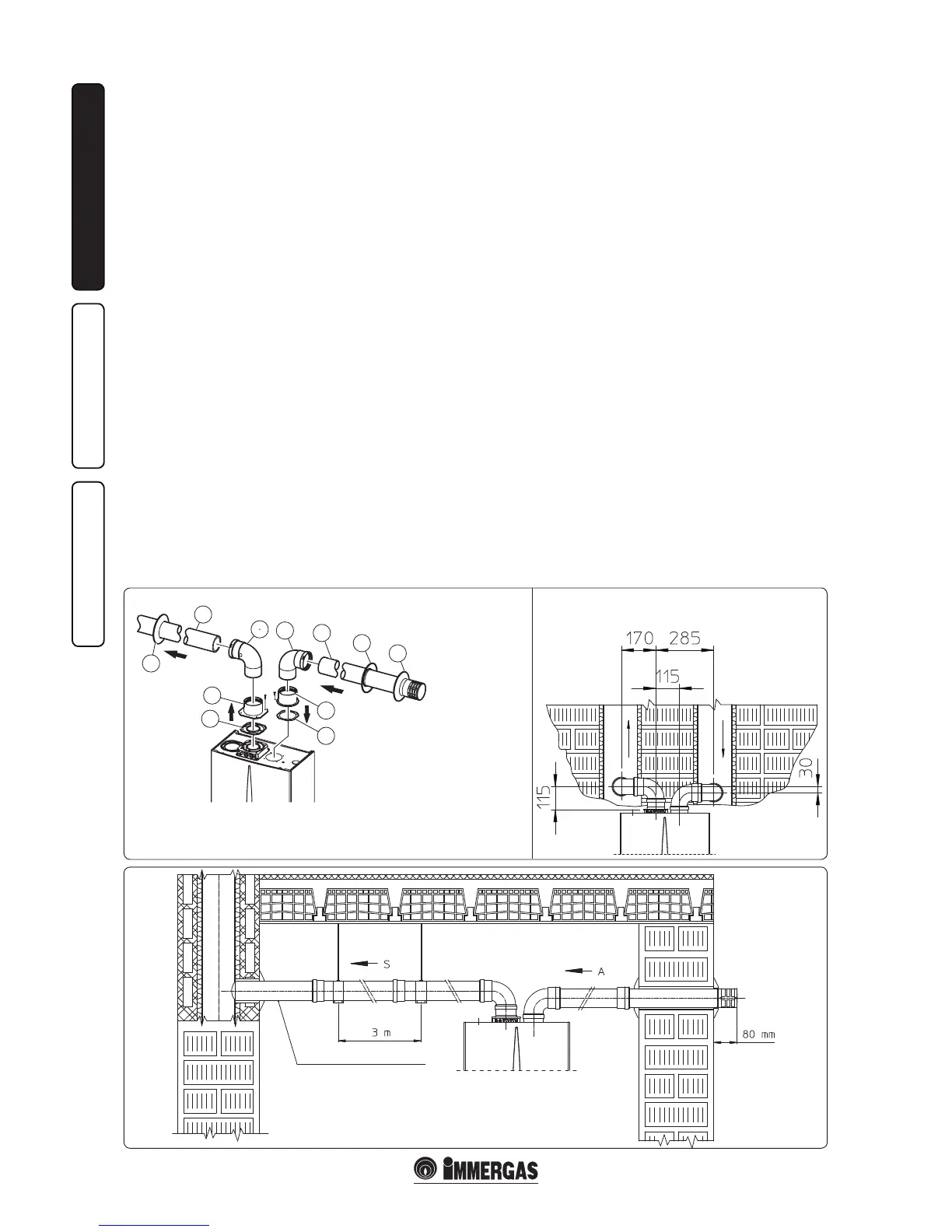

Separator kit Ø 80/80. e Ø 80/80 separator

kit, allows separation of the exhaust ues and

air intake pipes according to the diagram shown

in the gure. Combustion products are expelled

from pipe (S) (in plastic, so as to resist acid

condensate). Air is taken in through duct (A) for

combustion (this is also in plastic). e intake

pipe (A) can be installed either on the right or

le hand side of the central exhaust pipe (S). Both

ducts can be routed in any direction.

• Kit assembly (Fig. 1-23): install the ange (4)

on the central hole of the boiler, positioning the

gasket (1) (which does not require lubrication)

positioning it with the circular projections

downwards in contact with the boiler ange

and tighten using the hex screws with flat

end present in the kit. Remove the at ange

present in the lateral hole with respect to the

central one (according to needs) and replace it

with the ange (3), positioning the gasket (2)

already present in the boiler and tighten using

the supplied self-threading screws. Fit the male

end (smooth) to the bends (5) in the female end

of the anges (3 and 4). Fit the intake terminal

(6) with the male section (smooth) in the

female section of the bend (5) up to the stop,

ensuring that the internal and external wall

sealing plates are tted. Fit the exhaust pipe

(9) with the male end (smooth) to the female

end of the bend (5) up to the stop; making sure

that the internal wall sealing plate has been

tted, this will ensure sealing and joining of

the elements making up the kit.

• Coupling of extension pipes and elbows. To

install push-fitting extensions with other

elements of the flue extraction elements

assembly, proceed as follows: Install the pipe

or elbow with the male side (smooth) on the

female section (with lip seal) to the end stop

on the previously installed element. is will

ensure sealing and joining of the elements

correctly.

• Installation clearance (Fig. 1-24). e minimum

installation clearance measurements of the Ø

80/80 separator terminal kit have been stated

in some limit conditions.

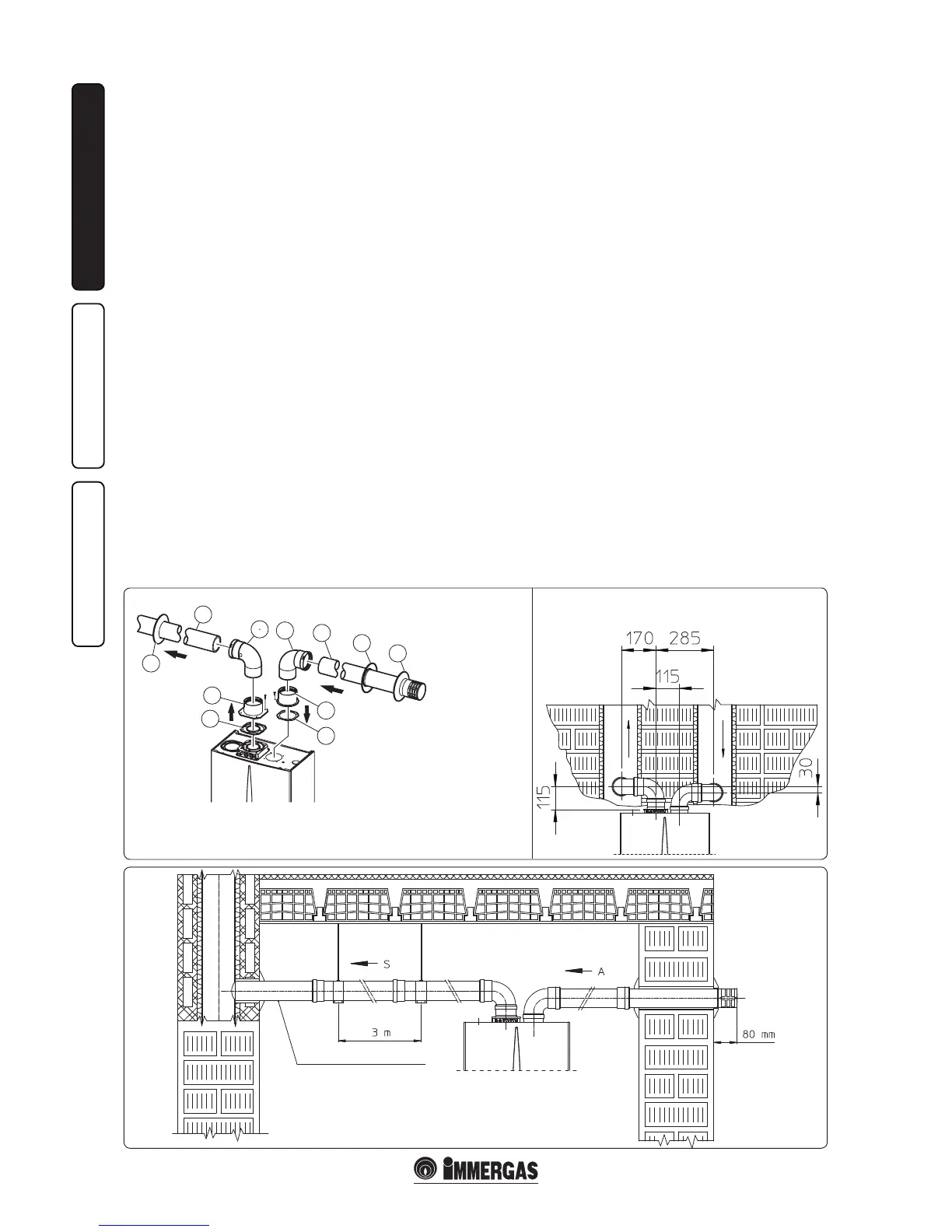

• Extensions for Ø 80/80 separator kit. The

maximum vertical straight length (without bends)

that can be used or Ø 80 intake and exhaust pipes

is 41 metres, independently to whether they

are used for intake or exhaust. e maximum

horizontal straight length (with bend in suction

and in exhaust) that can be used or Ø 80 intake

and exhaust pipes is 36 metres independently to

whether they are used for intake or exhaust.

N.B.: to favour the removal of possible condensate

forming in the exhaust pipe, tilt the pipes towards

the boilers with a min. slope of 1.5%. (Fig. 1-25).

When installing the Ø 80 ducts, a section clamp

with pin must be installed every 3 metres.

• Conguration type B

23

open chamber and

forced draught.

e appliance can be installed inside buildings in

B

23

mode; in this eventuality, all technical rules

and national and local regulations in force, must

be complied with.

e kit includes:

N° 1 - Exhaust gasket (1)

N° 1 - Flange gasket (2)

N° 1 - Female intake ange (3)

N° 1 - Female exhaust ange (4)

N° 2 - Bend 90° Ø 80 (5)

N° 1 - Intake terminal Ø 80 (6)

N° 2 - Internal white wall sealing plates (7)

N° 1 - External grey wall sealing plate (8)

N° 1 - Exhaust pipe Ø 80 (9)

- Type B open chamber boilers must not be

installed in places where commercial, artisan

or industrial activities take place, which use

products that may develop volatile vapours

or substances (e.g. acid vapours, glues, paints,

solvents, combustibles, etc.), as well as dusts

(e.g. dust deriving from the working of

wood, coal nes, cement, etc.), which may be

damaging for the components of the appliance

and jeopardise functioning.

- in type B

23

conguration, the boilers must not

be installed in bedrooms, bathrooms or in

bedsitters.

- The installation of appliances in B

23

conguration is only recommended outdoors

(in a partially protected place) or in places that

are not lived in and which are permanently

ventilated.

1.12 DUCTING OF FLUE TECHNICAL

SLOTS.

Ducting is an operation through which by the

introduction of one or more relevant pipes,

a system is realised for the evacuation of the

combustion products of a gas appliance made

up from the coupling of an existing or new

ducting pipe with a chimney, ue or technical

slot (also in new buildings) (Fig. 1-24). Ducting

requires the use of ducts declared to be suitable

for the purpose by the manufacturer, following

the installation and user instructions, provided

by the manufacturer and the requirements of

the standards.

Minimum slope 15%

Loading...

Loading...