18 - IE

INSTALLERUSERTECHNICIAN

Each time the burner ignites, the relative ame

present symbol is displayed (10) with relative

power scale.

• Operation with Comando Amico Remoto

remote control

V2

(CAR

V2

) (Optional). If the

CAR

V2

is connected, the (

) symbol will

appear on the display. e boiler regulation

parameters can be set via the CAR

V2

control

panel and the reset button (3) remains active

on the boiler control panel, along with the

switch-o button (1) (“o” mode only) and the

display where the functioning state is shown

Important: if the boiler is put into "off "

mode, the “ERR>CM” connection error

symbol will appear on the CAR

V2

. e CAR

V2

is

however powered constantly so as not to loose

memorised programs.

• Solar functioning mode (

). is function

is activated automatically if the boiler detects

a probe on the DHW inlet (optional) or if the

“Solar ignition delay” parameter is more than

0 seconds.

During a withdrawal, if the outlet water is

hot enough, the boiler does not switch on,

the DHW withdrawal symbol (

) appears

on the display along with the ashing solar

function symbol (

).

When the water supplied by the solar system

is at a temperature lower than that at which

the boiler is set, the boiler switches on. At this

point, the solar function symbol will stay on

without ashing.

• Functioning with optional external probe

(

). In the case of a system with optional

external probe, the boiler ow temperature

for room central heating is managed by the

external probe depending on the external

temperature measured (Par. 1.6). The flow

temperature can be modied by selecting the

functioning curve via the selector switch (6)

(or on the CAR

V2

control panel, if connected

to the boiler) selecting a value from “0 to 9”.

With external probe present, the relative

symbol (18) will appear on the display. In the

central heating phase, if the temperature of the

water contained in the system is sucient to

heat the radiators, the boiler can only function

with the activation of the pump.

• “Stand-by” mode. Press button (1) in

succession until the (

) symbol appears.

e boiler remains inactive from this moment

and the anti-freeze function, pump anti-block

function and 3-way and signalling of any

anomalies is guaranteed.

N.B.: in these conditions the boiler is

considered still powered.

• “O” mode. By holding the button (1) down

for 8 seconds, the display switches-o and the

boiler is o completely. e safety functions are

not guaranteed in this mode.

N.B.: in these conditions the boiler is considered

still live even if there are no functions active.

• “Automatic vent” mode. Every time power is

supplied to the boiler. the system automatic

vent function is activated (duration 8 minutes).

This function is displayed via countdown

signalled by the indicator (14). During this

period the DHW and CH functions are not

active.

The “automatic vent” can be annulled by

pressing the “reset” button (4).

• Display functioning. e display lights up

during the use of the control panel, aer 15

seconds inactivity, the brightness drops until

just the active symbols are displayed. The

lighting mode can be varied via parameter t3

in the circuit board customisation menu.

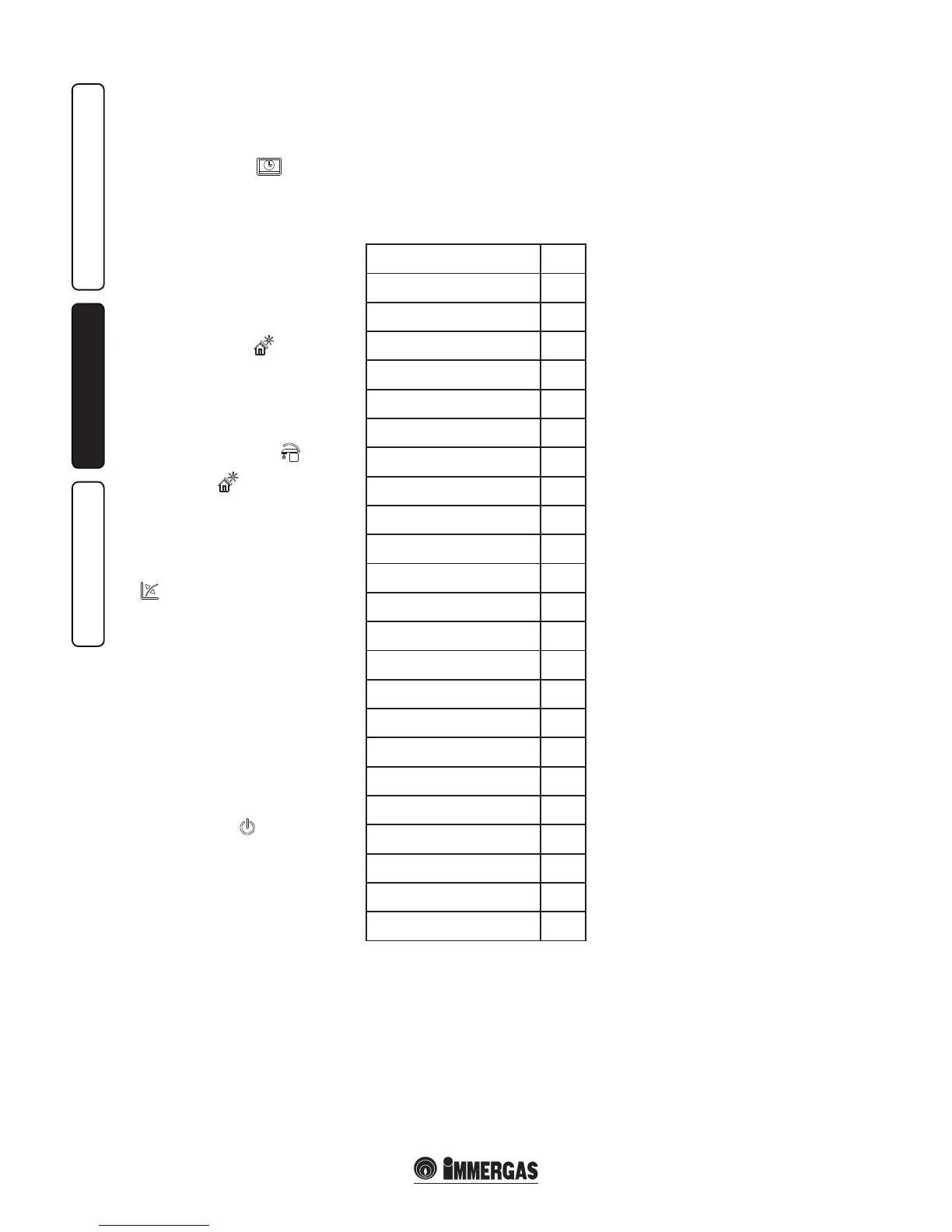

2.5 FAULT AND ANOMALY SIGNALS.

e Victrix 12 -24I boiler signals any anomalies

using a code shown on the boiler display (14)

according to the following table.

Anomaly signalled

Error

code

No ignition block 01

Safety thermostat block (over-

heating), ame control anomaly

02

Flue safety thermostat block 03

Contacts resistance block 04

Flow probe anomaly 05

Maximum N° of reset 08

Insucient system pressure 10

Storage tank probe anomaly

(optional)

12

Conguration error 15

Fan anomaly 16

Parasite ame block 20

Push button control panel anomaly 24

Block due to ue gas temperature

gradient intervention

25

Insucient circulation 27

Flue probe anomaly 29

Loss of remote control

communication

31

IMG Bus communication loss 36

Low power supply voltage 37

Loss of ame signal 38

Block due to loss of continuous

ame signal

43

Block for maximum time, partial

gas valve opening

44

Low temperature safety thermostat

(optional)

46

Burner power limitation 47

N.B.:on the Comando Amico Remoto

V2

remote

control (Optional), the error code corresponds

to the previous list with the “ERR>” indication in

front (E.g. code 01 CAR

V2

code ERR>01).

Ignition block. e boiler ignites automatically

with each demand for room central heating or

hot water production. If this does not occur

within the pre-established time, the boiler goes

into no ignition block. To eliminate “no ignition

block” the Reset button (3) must be pressed. On

commissioning or aer extended inactivity it

may be necessary to eliminate the “no ignition

block”. If this phenomenon occurs frequently,

contact a qualified technician for assistance

(e.g. Immergas Aer-Sales Technical Assistance

Service).

Safety thermostat block (over-heating), ame

control anomaly. During regular operation, if a

fault causes excessive overheating internally or

an anomaly occurs in the ame control section,

an overheating block is triggered in the boiler. To

eliminate “overheating block” the Reset button

(3) must be pressed. If this phenomenon occurs

frequently, contact a qualied technician for

assistance (e.g. Immergas Aer-Sales Technical

Assistance Service).

Flue safety thermostat block. is occurs in

the case of partial internal obstruction (due to

the presence of lime scale or mud) or external

blocking should occur (combustion residues)

to the condensation module. To eliminate the

“flue thermostat block” the Reset button (3)

must be pressed. Call an authorised technician

to remove the obstructions (e.g. Immergas Aer-

sales Service).

Contacts resistance block. is occurs in the

case of faults to the safety thermostat (over-

temperature) or anomaly in the ame control.

e boiler does not start and a technician must

be called (e.g. Immergas Aer-Sales Service).

System ow probe anomaly. If the board detects

an anomaly on the system NTC ow probe, the

boiler will not start; contact a qualied technician

for assistance (e.g. Immergas Aer-Sales Service).

Maximum N° of reset. To eliminate any

anomaly, the Reset button (3) must be pressed.

e Anomaly can be reset 5 times consecutively,

aer which the function in inhibited for at least

one hour. One attempt is gained every hour for

a maximum of 5 attempts.

Insucient system pressure. Water pressure

inside the central heating system that is sucient

to guarantee the correct functioning of the boiler

is not detected. Check on the boiler manometer

(7) that the system pressure is between 1÷1.2

bar and restore the correct pressure if necessary.

Storage tank probe anomaly (optional). If

the board detects an anomaly on the storage

tank probe, the boiler cannot produce DHW

and signals an anomaly; if necessary contact a

qualied technician for assistance (e.g. Immergas

Aer-Sales Technical Assistance Service).

Conguration error. If the board detects an

anomaly or incongruency on the electric wiring,

the boiler will not start. If normal conditions are

restored the boiler restarts without having to be

reset. If this anomaly persists, contact a qualied

technician for assistance (e.g. Immergas Aer-

Sales Service).

Fan anomaly. This occurs if the fan has a

mechanical or electrical fault. To eliminate the

“fan anomaly” the Reset button (3) must be

pressed. Call an authorised technician if the

anomaly persists (e.g. Immergas After-sales

Service).

Loading...

Loading...