12

2.5 ELECTRICAL INSTALLATION

Before proceeding further, we recommend that you

review the safety data in the front of this manual.

Locate the compressor data plate on the left end of

the cooler box next to the control box (See Figure

2.5-1).

The data plate lists the rated operating pressure, the

maximum discharge pressure, the electric motor char-

acteristics and power.

Confirm that the line voltage and compressor name-

plate voltage are the same.

The standard control box meets the intent of NEMA 1

guidelines.

It will be necessary to make a hole in the control box

for the incoming power connection. Care should be

taken to not allow metal shavings to enter the starter

and other electrical components within the box. After

making the power inlet hole, all shavings and debris

must be removed from inside of control box before

power is turned on.

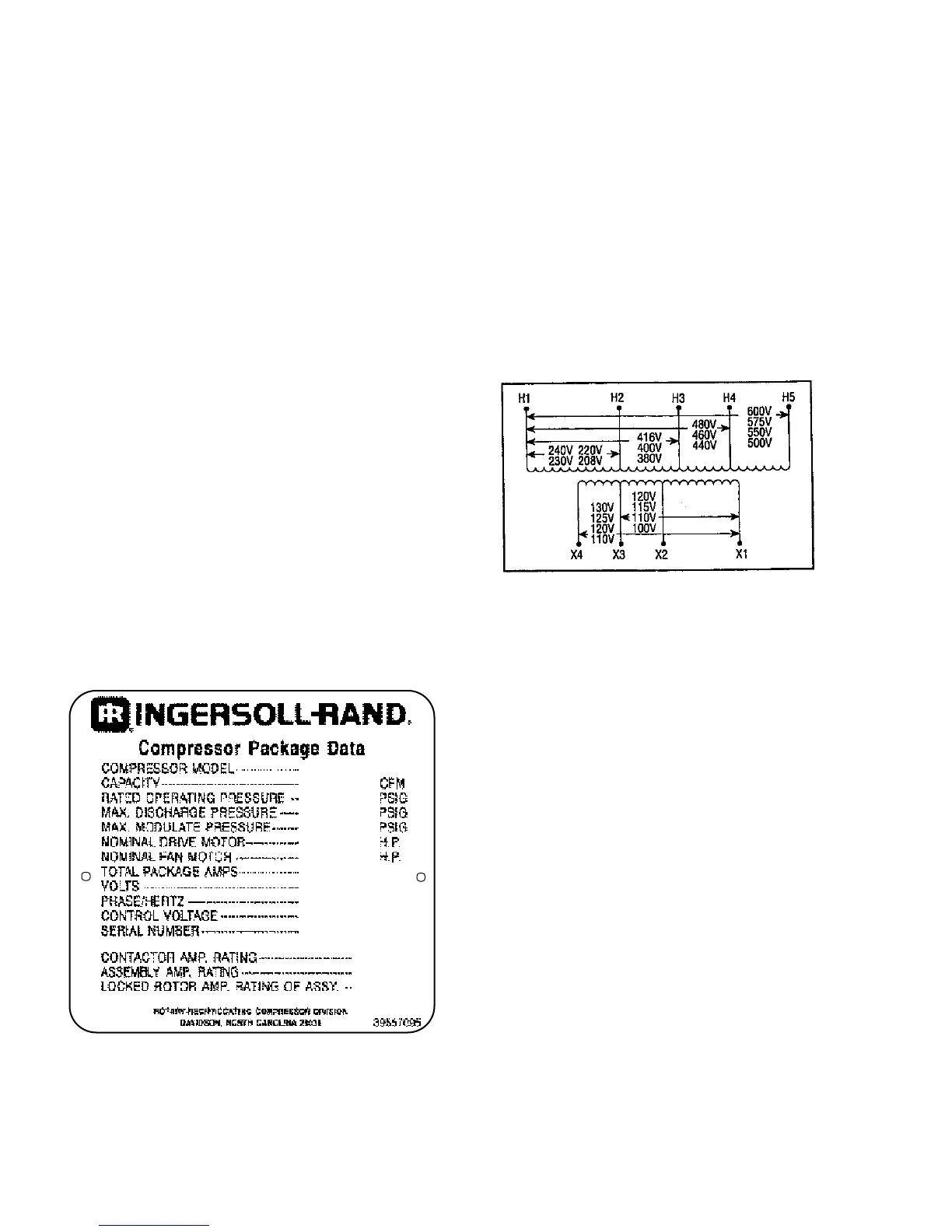

Incoming power should be connected per the electri-

cal schematic at the rear of this manual (See Section

6.0). Confirm that all electrical connections are made

and tightened. Confirm that the control transformer is

wired correctly for supply voltage (See Figure 2.6-1).

FIGURE 2.6-1 CONTROL TRANSFORMER

CONNECTIONS

PRIMARY

SECONDARY

Inspect the motor and control wiring for tightness.

Replace control box door.

2.6 VOLTAGE CONVERSION

IMPORTANT:This procedure should only be carried out

by a qualified electrician, electrical contractor or your

local Ingersoll Rand Distributor or Air Center.

FIGURE 2.5-1 COMPRESSOR DATA PLATE

NOTE:This procedure applies only to units manufac-

tured to multi-voltage specifications. Compressor data

plate and motor nameplate must indicate multiple volt-

ages.

Loading...

Loading...