21

9. Remove seal housing from airend assembly. Use

the removal slots provided to pry the seal housing

from the airend. Do not attempt to break the seal

housing loose by tapping.

10. Drive each seal out of the housing, being careful

not to damage the surface of the bore.The larger

double lip seal must be driven out toward the

inboard side.The term “inboard” side of the seal

housing will refer to the face that is mounted to the

airend assembly.The term “outboard” side will refer

to the face closest to the sheave.

11. Discard seals.

12. Remove check valve ball and plug from seal

housing.

13. Remove wear sleeve from shaft, being careful

not to damage the shaft.

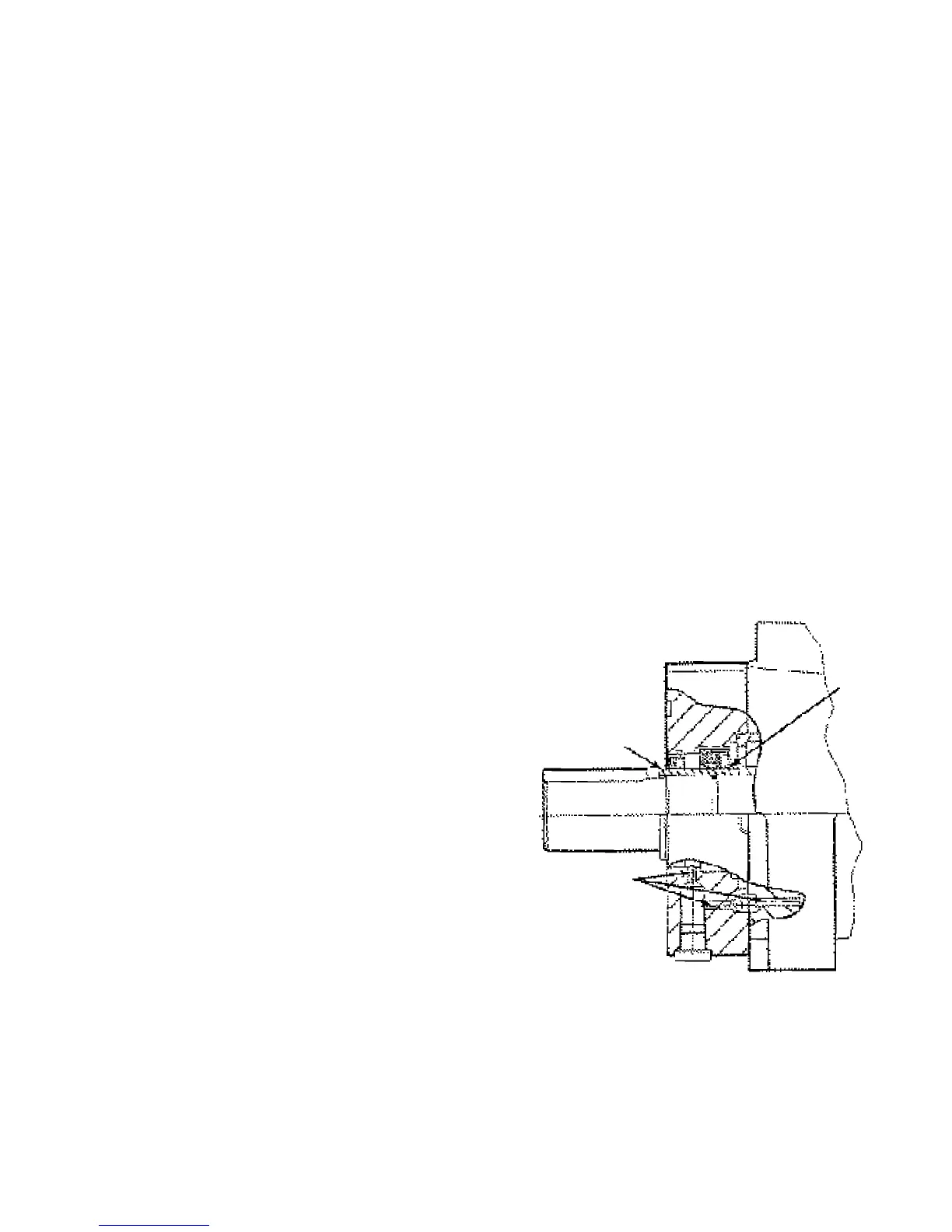

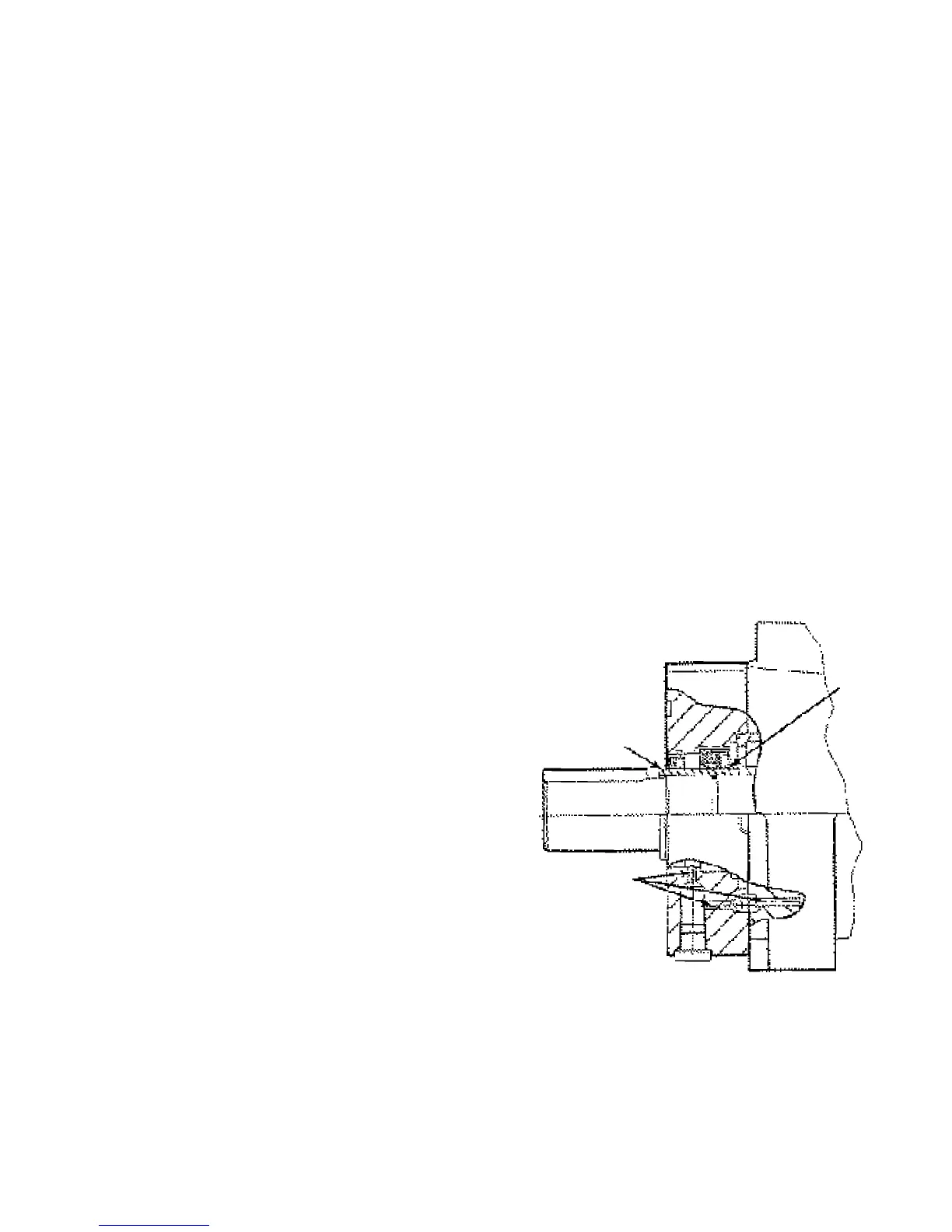

14.Thoroughly clean the scavenge holes, (See

Figure 4.8-1), bore surfaces of the seal housing,

wear sleeve journal on the shaft, and the face of the

airend assembly.Be careful not to damage any of

the surfaces, and insure that no particles are

allowed to enter the bearings.

FIGURE 4.8-1 SHAFT SEAL ASSEMBLY

LIP EDGE

OF SEAL

INWARD

WEAR

SLEEVE

SCAVENGE

HOLES

4.8 SHAFT SEAL REPLACEMENT

There are two lip type seals on the compressor.They

are wearable parts and should be replaced at 8,000

hour intervals.While it is advisable to have your local

Ingersoll-Rand Distributor or Air Center perform this

work, the task can be accomplished by a good mechanic

following these instructions.

Before beginning any work on the compressor,

open, lock and tag the main electrical disconnect

and close the isolation valve on the compressor dis-

charge.Wait 2 minutes after stopping to allow inter-

nal pressure to dissipate.Vent residual pressure

from the unit by slowly unscrewing the coolant fill

plug one turn. Unscrewing the fill plug opens a vent

hole, drilled In the plug, allowing the pressure to

release to atmosphere (See Figure 4.3-1). A slight

mist or oil droplets may be visible during venting.

Do not remove fill plug until all pressure has vented

from the unit. Also vent piping by slightly opening

the drip leg valve.When opening the drain valve or

removing the coolant fill plug, stand clear of the

valve discharge, wear work gloves and appropriate

eye protection.

SPECIAL TOOLS

A clean work bench

Seal installation tool

REPLACEMENT PARTS

Shaft seal kit

Seal retainer 0-Ring

Loctite® 609

Loctite® 515

Installation

1. Remove the cooler box rear panel.

2. Remove belts (See Section 4.6).

3. Remove the three hex lead screws that hold the

sheave to the sheave bushing (See Figure 4.5-3).

4. Lubricate the thread and end of screws that were just

removed.

5. Reinstall all three screws in the holes of the bushing

that are threaded.

6. Slowly tighten the three screws evenly until the

sheave is pressed from the bushing. (Light tapping on

bushing may assist removal.)

7. Remove the screws from the holes.

8. Loosen allen screw in sheave bushing.

Loading...

Loading...