13

2.7 ROTATION CHECK.

Locate the rotation decal on the motor and check for

correct rotation.The correct rotation when viewed from

the opposite drive end of the motor is clockwise.

If compressor is operated in the opposite direction of

rotation, airend damage can result and is not war-

rantable.

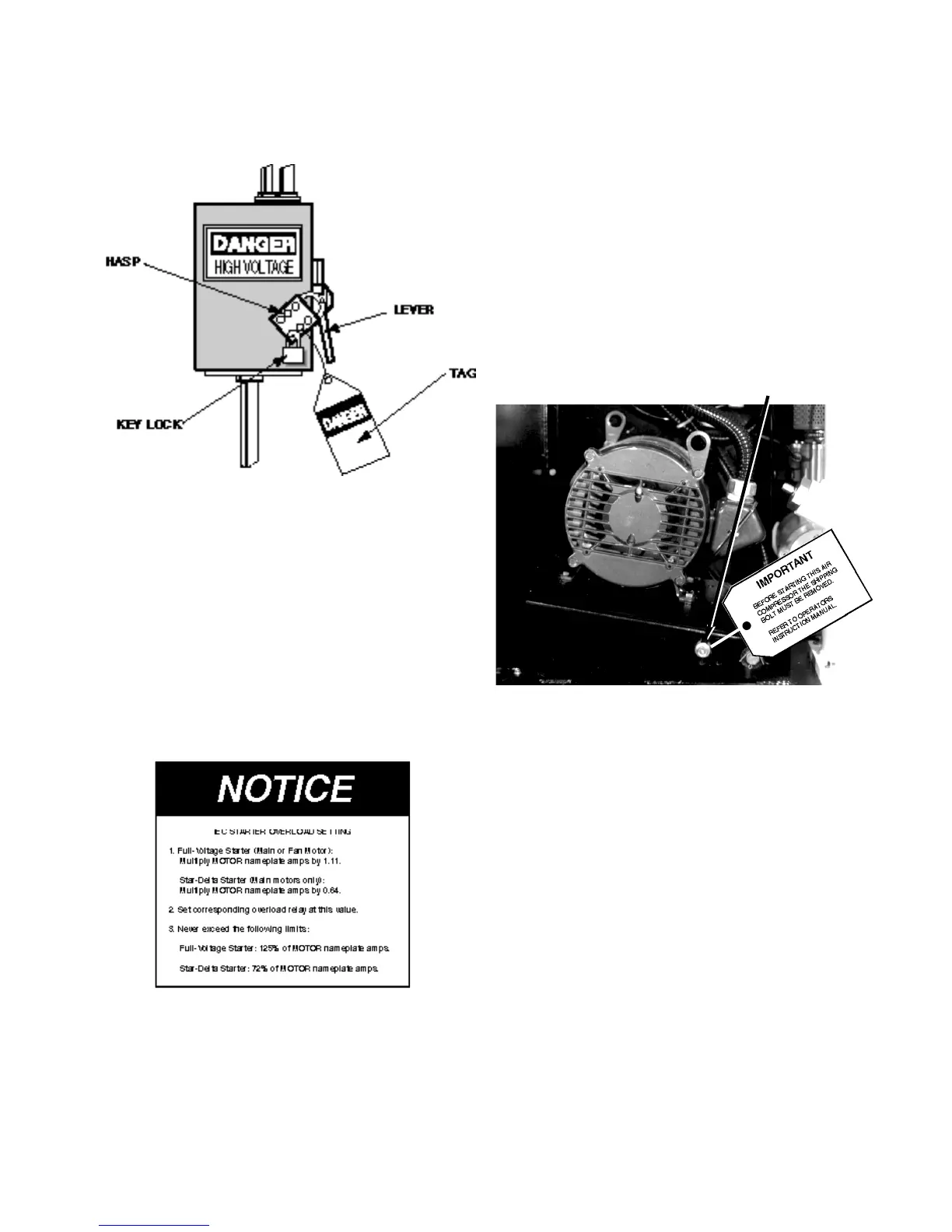

The unit is shipped with a bolt in the motor support to

prevent possible belt damage caused by bouncing dur-

ing shipment.This bolt must be remove prior to check-

ing motor rotation or operating the unit.

Locate the shipping bolt in the motor support as shown

in Figure 2.7-1. and remove.

For the compressor motor rotation check, the motor

jogging should be as short a time as possible.

1. Ensure that the Stop button is in the stop

(depressed) position.

2. Check coolant level.To check coolant level, slowly

loosen the fill plug one complete turn. As the fill plug is

unscrewed approximately one turn, a small amount of

pressure may be released. Do not remove the fill plug

until all pressure has been vented. Once pressure is

vented, finish removing the fill plug.The proper coolant

level is when the coolant is even with the top of the fill

port. Add coolant if necessary.

3. Replace and tighten fill plug.

4. Close the main disconnect switch (ON position).

5.Verify that the main isolation valve is open.

6. Open the canopy enclosure if machine is so

FIGURE 2.7-1 SHIPPING BOLT LOCATION

SHIPPING BOLT

PROCEDURE:

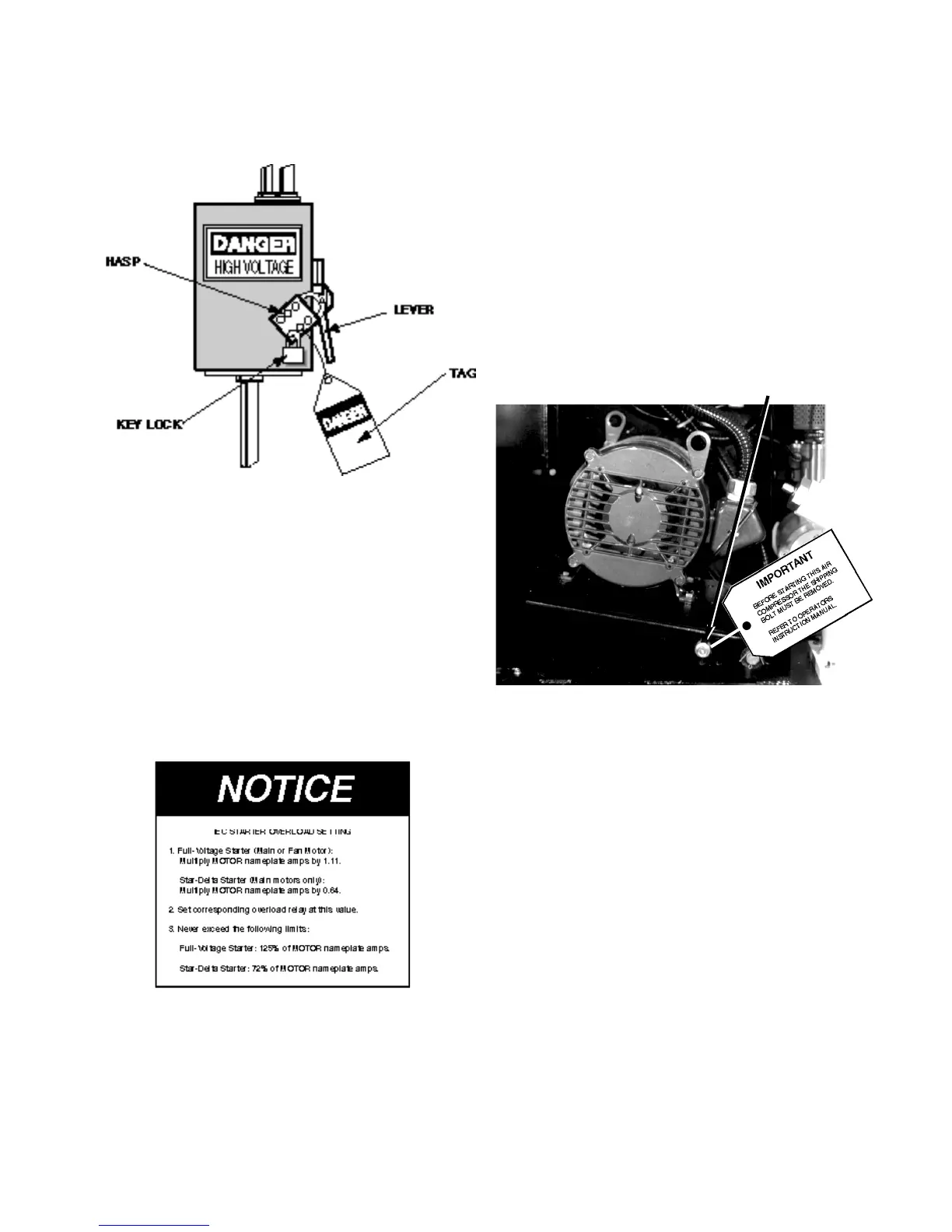

Put main disconnect in the OFF position, lock and tag

(See Figure 2.6-2).

Open the motor junction box on the side of the motor.

Reconnect the motor to the desired voltage. Use the

connection diagram provided on the motor as a guide.

Reconnect the primary side of the control transformer

for the desired voltage, as shown on the control trans-

former wiring decal.

Adjust motor overload setting as outlined below in

Figure 2.6-3.

FIGURE 2.6-3 MOTOR OVERLOAD SETTING

Make sure all wiring connections are tight.

Put main disconnect in the ON position and check

motor rotation, as outlined in Section 2.7 of this manu-

al.

FIGURE 2.6-2 MAIN DISCONNECT

LOCKED AND TAGGED

Loading...

Loading...