26

Before beginning any work on the compressor,

open, lock and tag the main electrical disconnect

and close the isolation valve on the compressor

discharge.Wait 2 minutes after stopping to allow

internal pressure to dissipate.Vent residual pres-

sure from the unit by slowly unscrewing the

coolant fill plug one turn. Unscrewing the fill plug

opens a vent hole, drilled in the plug, allowing the

pressure to release to atmosphere (See Figure 4.3-

1). A slight mist or oil droplets may be visible dur-

ing venting. Do not remove fill plug until all pres-

sure has vented from the unit. Also vent piping by

slightly opening the drip leg valve. When opening

the drain valve or removing the coolant fill plug,

stand clear of the valve discharge, wear work

gloves and appropriate eye protection.

Procedure:

1. Disconnect tank discharge fitting, inlet valve control

tubing, and scavenge tube.

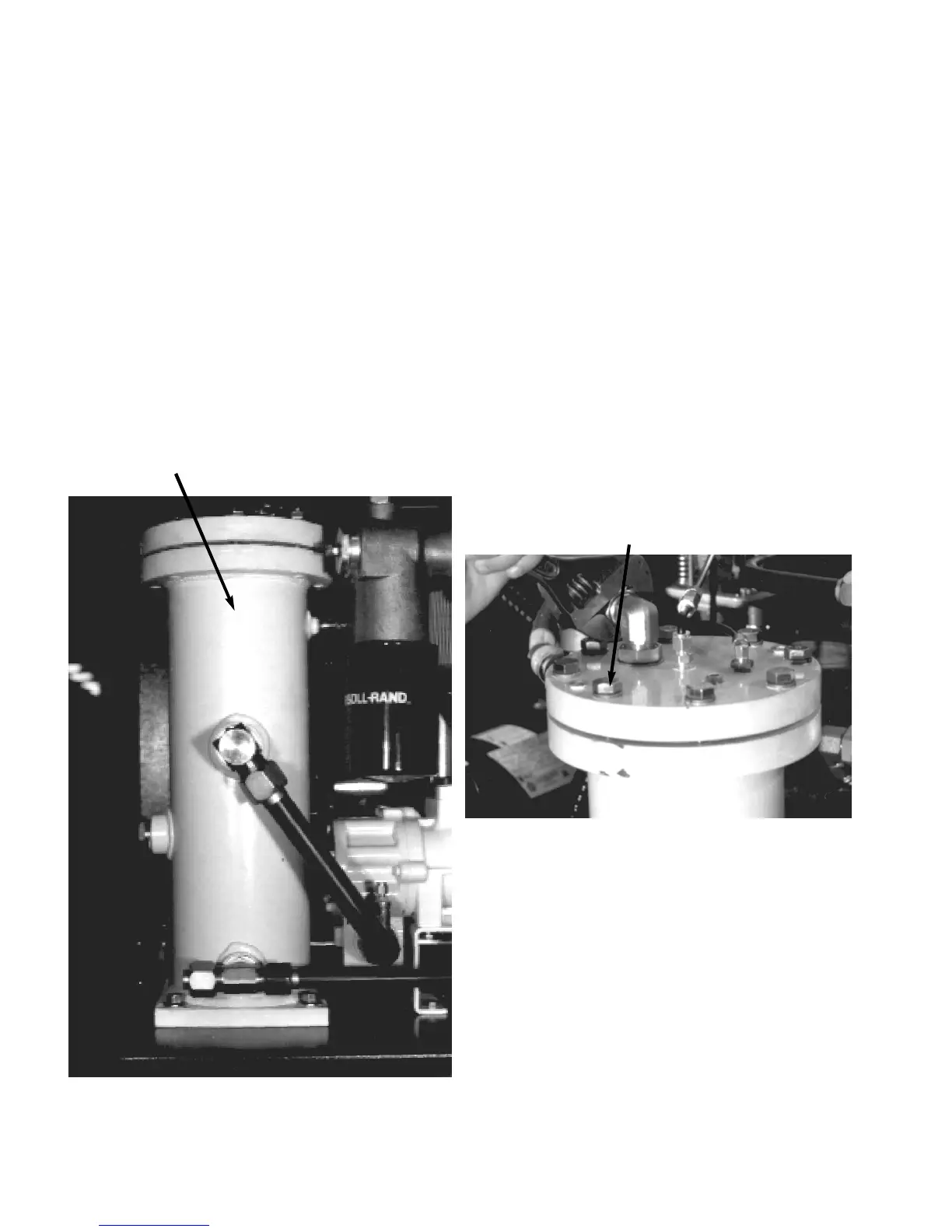

2. Remove tank cover bolts and cover (See Figure

4.13-2).

3. Remove separator element.

4. Clean all tank flange surfaces of dirt and residual

gasket material.

5. Install new separator element, making sure that the

grounding staple comes in contact with the flange

material.

FIGURE 4.13-2 TANK COVER REMOVAL

BOLT

Installation

Install the new hose. Refill the unit with coolant. Start

the compressor and check for leaks. Stop unit and

check coolant level in the sight glass on the separator

tank.

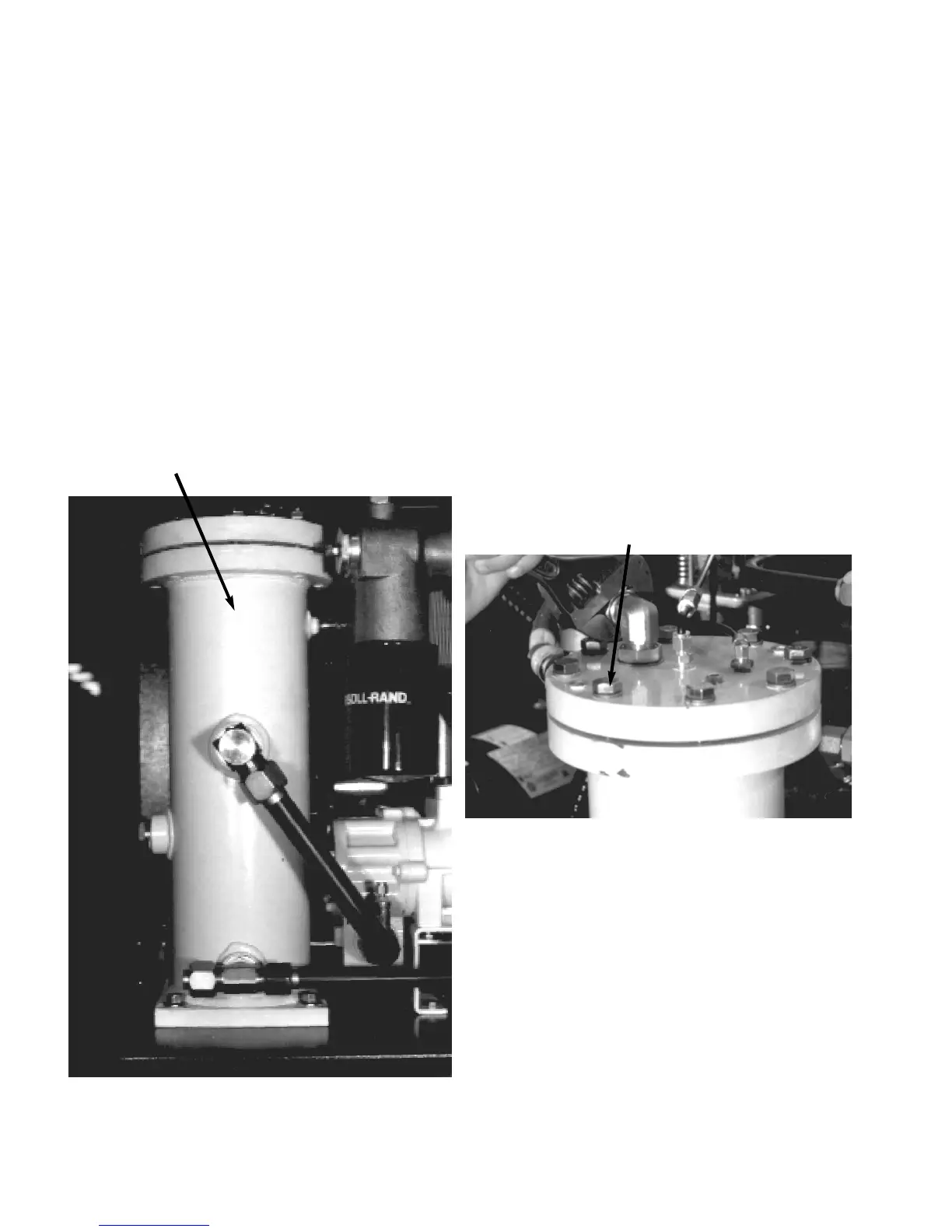

4.13 COOLANT SEPARATOR ELEMENT

The separator element should be replaced every year

or after 4000 hours of operation, whichever comes

first, to prevent excessive coolant carryover into the

plant’s air piping system.

The element is located inside the separator tank (See

Figure 4.13-1).

FIGURE 4.13-1 SEPARATOR ELEMENT LOCATION

SEPARATOR ELEMENT (INSIDE)

Loading...

Loading...