17

4.0 MAINTENANCE

4.1 MAINTENANCE SCHEDULE

THE MAINTENANCE SCHEDULE SPECIFIES ALL RECOMMENDED MAINTENANCE REQUIRED TO KEEP THE COM-

PRESSOR IN GOOD OPERATING CONDITION.SERVICE AT THE INTERVAL LISTED OR AFTER THAT NUMBER OF

HOURS, WHICHEVER OCCURS FIRST.

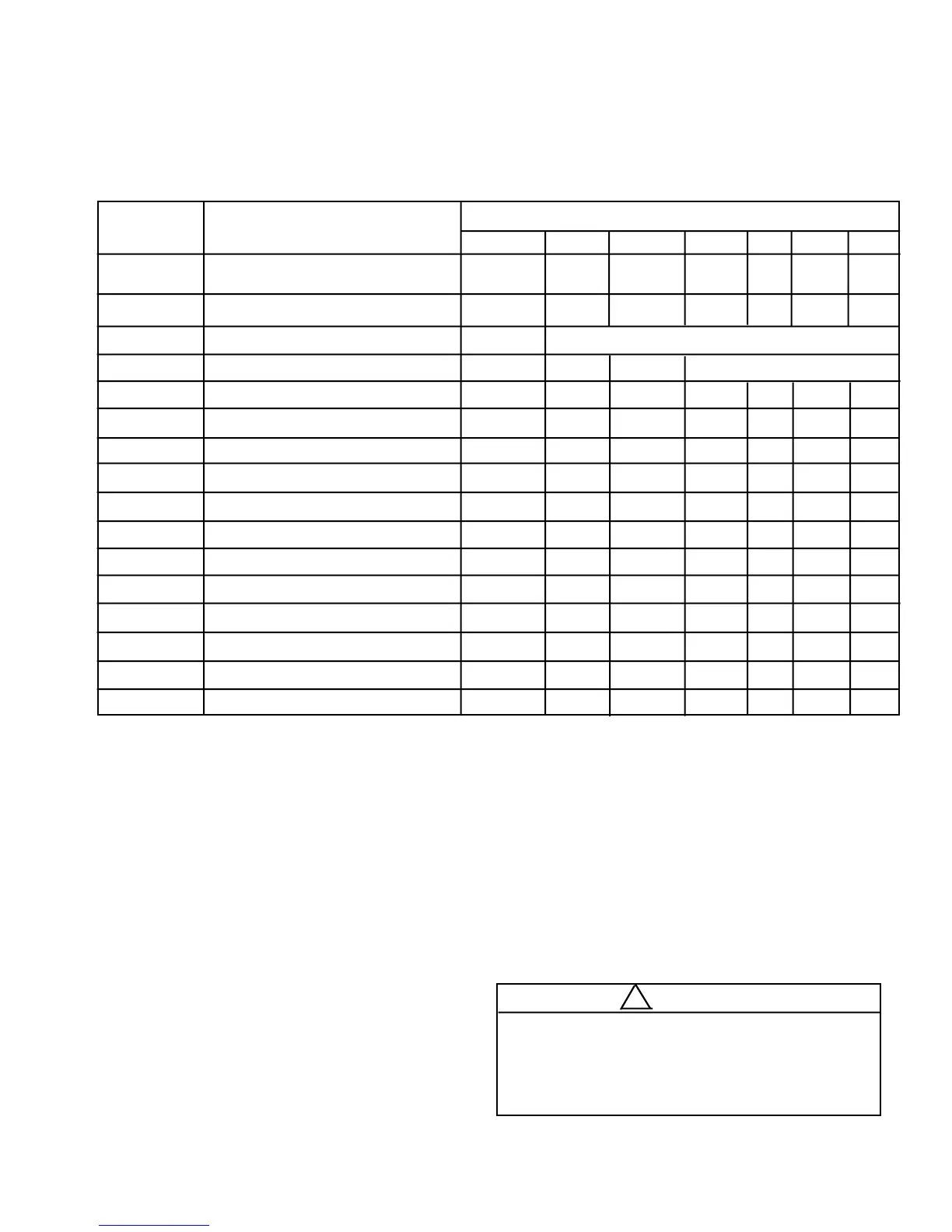

ACTION PART OR ITEM HOURS 1WK 1 MO 6 MO 9 MO YEARLY 2YR

INSPECT COOLANT LEVEL VISIBLE IN FILL PORT WEEKLY X

(WHEN COLD)

INSPECT AIR FILTER WEEKLY X

REPLACE COOLANT FILTER* 150 X

REPLACE COOLANT FILTER* 2000 X

INSPECT HOSES 1000 X

INSPECT DRIVE BELTS 500 X

REPLACE DRIVE BELTS 8000 X

CHECK HIGH AIR TEMP.SWITCH 1000 X

CHECK OPERATE PRESSURE RELIEF VALVES 1000 X

CLEAN SEPARATOR SCAVENGE ORIFICE 1000 X

CLEAN COOLERS CORES** 4000 X

REPLACE AIR FILTER* 2500 X

REPLACE SEPARATOR ELEMENT* 4000 X

REPLACE ULTRA COOLANT 8000 X

REPLACE SHAFT SEAL 8000 X

TIME INTERVAL (WHICHEVER COMES FIRST)

(INITIAL CHANGE ONLY)

(SUBSEQUENT CHANGES)

4.2 MAINTENANCE RECORDS

It is very important that you, the owner, keep accurate

and detailed records of all maintenance work you or

the Ingersoll-Rand Distributor or Air Center perform on

your compressor.This includes, but is not limited to,

coolant, coolant filter, separator element, inlet air filter,

drive belts, shaft seals and so forth.This information

must be kept by you, the owner, should you require

warranty service work by your Ingersoll-Rand

Distributor or Air Center. Maintenance record sheets

are located at the back of this manual.

4.3 MAINTENANCE PROCEDURES

Before starting any maintenance, be certain the follow-

ing is heeded.

Read Safety Instructions.

Have a well equipped mechanic’s tool box with English

and Metric sockets. (Special tools when needed will be

listed under each appropriate procedure).

Have an OSHA approved air nozzle and compressed

air. (International - local codes may apply).

Have recommended spare parts on hand (See listing

in back of this manual.

! WARNING

When the unit is shut down, residual pressure

can be trapped within the compressor system.

This pressure must be vented from the system

prior to beginning any service work.

*IN VERY CLEAN OPERATING ENVIRONMENTS AND WHERE INLET AIR FILTER IS CHANGED ATTHE ABOVE PRESCRIBED INTERVALS.IN EXTREME

DIRTY ENVIRONMENT CHANGE DRIVE BELTS, COOLANT, FILTERS, AND SEPARATOR ELEMENTS MORE FREQUENTLY.

**CLEAN COOLER CORES IF UNIT SHUTDOWN OCCURS ON HIGH AIR TEMPERATURE.

Loading...

Loading...