19

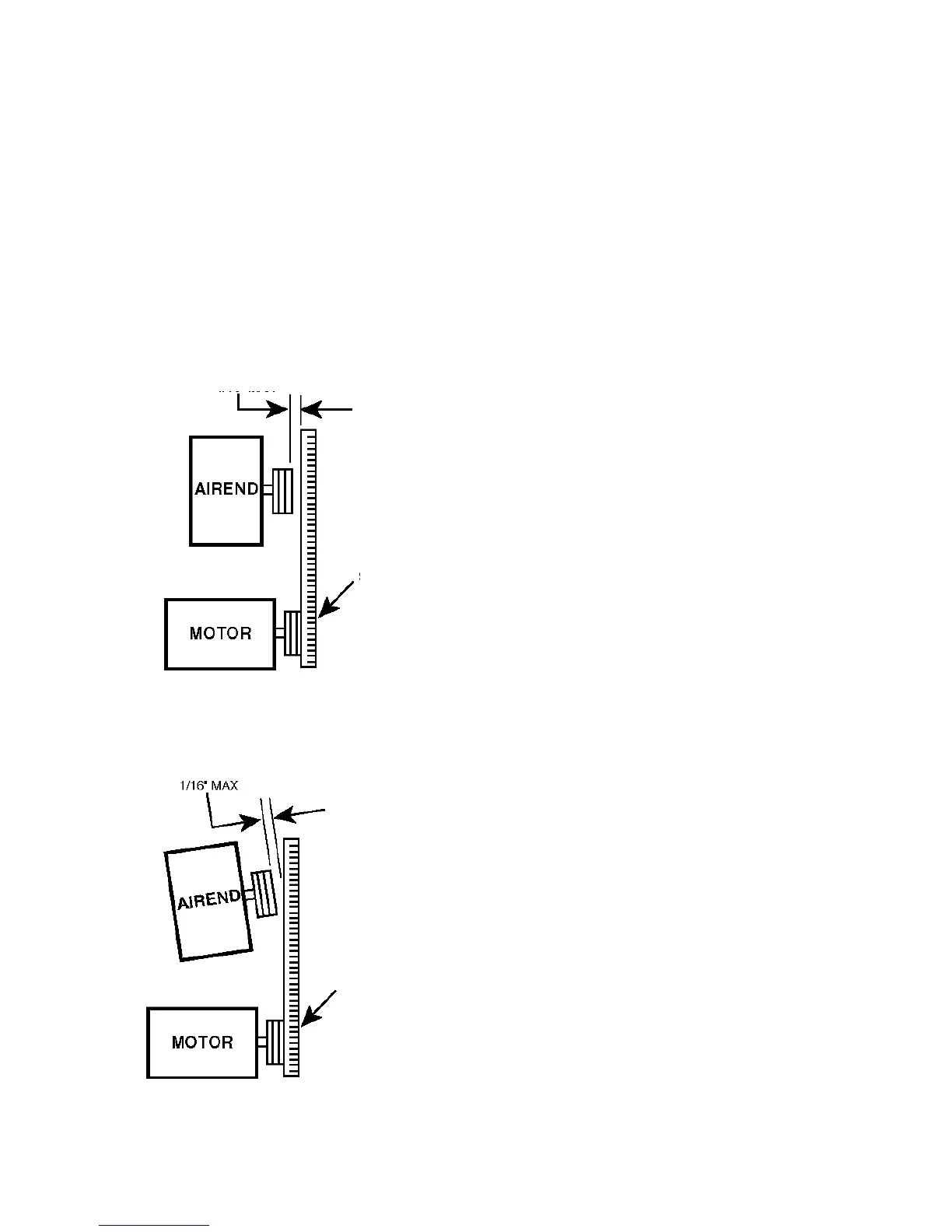

FIGURE 4.5-1 PARALLEL MISALIGNMENT

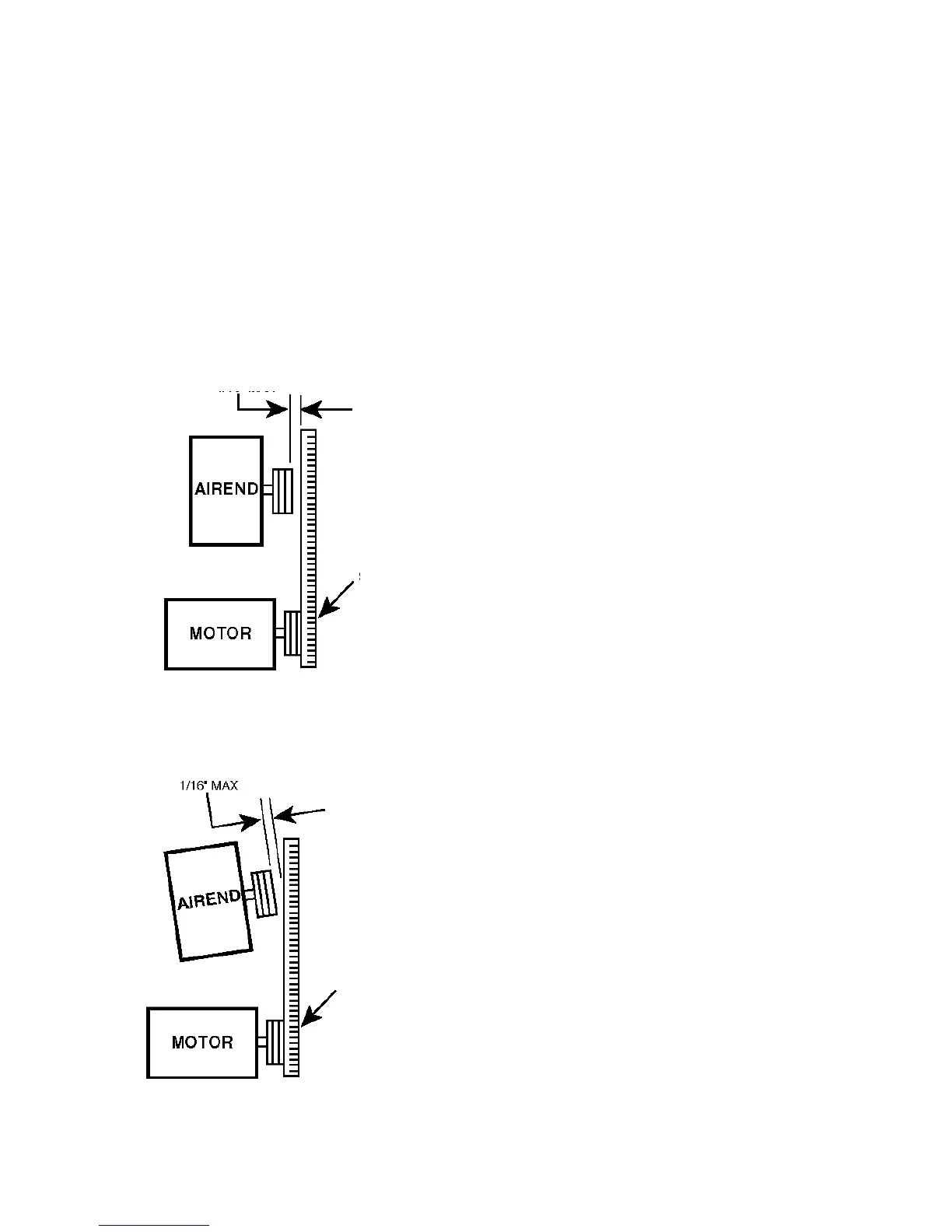

FIGURE 4.5-2 ANGULAR MISALIGNMENT

Align Sheaves

Ensure that the compressor is isolated from the

compressed air system by closing the isolation

valve and venting pressure from the drip leg.

Ensure that the main power disconnect switch is

locked and tagged.

An easy and effective method of checking alignment in

both directions between the driver and driven sheaves

utilizes an accurate straightedge.

Lay the straightedge across the face of the driver

(motor) sheave and check alignment of the driven

(airend) sheave.Then lay the straightedge across the

driven sheave and check that the driver sheave is

aligned.

Alignment should be within 1/16” (1.6 mm) maximum

when measuring the gap between the straightedge

and the rim of the opposite sheave in each direction.

This alignment is factory set and should only require

resetting if the drive motor or airend is removed.

The following steps should be taken to insure proper

alignment of all components.

1. Remove the cooler box top panel.

2. Holding the straightedge against the front of the

airend sheave, measure the amount of misalignment

seen on the motor sheave. If misalignment is less than

1/16” (1.6 mm) then reinstall cooler box panel prior to

operating unit.

3. If misalignment is more than 1/16” (1.6 mm), the

motor sheave bushing must be loosened for reposi-

tioning.

To reposition the motor sheave:

1. Remove drive belts (See Section 4.6).

2. Remove the three hex head screws that hold the

sheave to the sheave bushing. See Figure 4.5-3.

3. Lubricate the thread and end of screws that were

just removed.

4. Reinstall all three screws in the holes of the bushing

that are threaded.

5. Slowly tighten the three screws evenly until the

sheave is pressed from the bushing. (Light tapping on

bushing may assist removal.)

6. Remove the screws from the holes.

1/16” (1.6mm) MAX

1/16” (1.6mm) MAX

STRAIGHTEDGE

STRAIGHTEDGE

4.5 SHEAVE ALIGNMENT

Any degree of sheave misalignment will result in a

reduction of belt life. Misalignment of belt drive should

not exceed 1/16 in. (1.6 mm).

Parallel misalignment occurs when the drive and dri-

ven shafts are parallel, but the two sheaves lie in dif-

ferent planes (See Figure 4.5-1).

Angular misalignment occurs when the two shafts are

not parallel (See Figure 4.5-2).

Loading...

Loading...