18

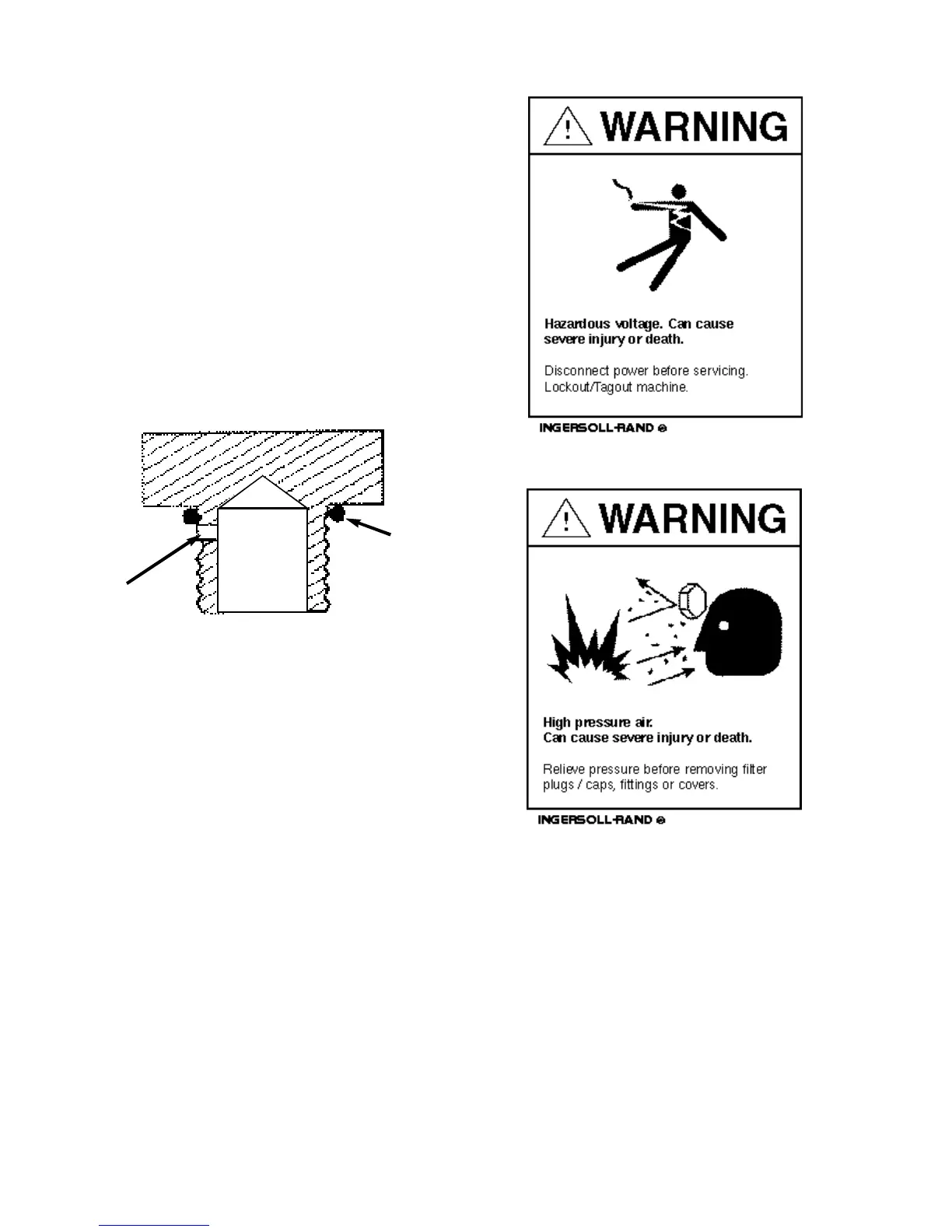

Before beginning any work on the compressor, open,

lock and tag the main electrical disconnect and

close the isolation valve on the compressor dis-

charge.Wait 2 minutes after stopping to allow inter-

nal pressure to dissipate.Vent residual pressure

from the unit by slowly unscrewing the coolant fill

plug one turn. Unscrewing the fill plug opens a vent

hole, drilled in the plug, allowing the pressure to

release to atmosphere (See Figure

4.3-1). A slight mist or oil droplets may be visible

during venting. Do not remove fill plug until all pres-

sure has vented from the unit. Also vent piping by

slightly opening the drip leg valve.When opening

the drain valve or removing the coolant fill plug,

stand clear of the valve discharge, wear work gloves

and appropriate eye protection.

4.4 PRESSURE RELIEF VALVE CHECK

Under normal operating condition a “try lever test” must

be performed every month . Under severe service condi-

tions, or if corrosion and/or deposits are noticed within

the valve body, testing must be performed more often. A

“try lever test” must also be performed at the end of any

non-service period. CAUTION! High pressure air will

discharge through the discharge ports of the valve

during “try lever test”.Wear ample clothing, gloves,

safety glasses and ear protection during valve test-

ing. Run the compressor for about 10 minutes by vent-

ing air from the system to let the unit warm up.With the

unit running, test at or near maximum operating pressure

by holding the test lever fully open for at least 5 seconds

to flush the valve seat free of debris.Then release lever

and permit the valve to snap shut. If lift lever does not

activate, or there is no evidence of discharge, discontin-

ue use of equipment immediately and contact a licensed

contractor or qualified service personnel.

FIGURE 4.3-1 COOLANT FILL PLUG WITH

VENT HOLE

VENT

HOLE

O-RING

Loading...

Loading...