7 MAINTENANCE AND LUBRICATION

en-80

7.16 WHEEL MOUNTING PROCEDURE____________________________________________

Remove dirt, grease and oil from the stud threads. Do not lubricate threads.

Put the wheel on the hub. Inspect the wheel to make sure of full contact between surface of

wheel and hub.

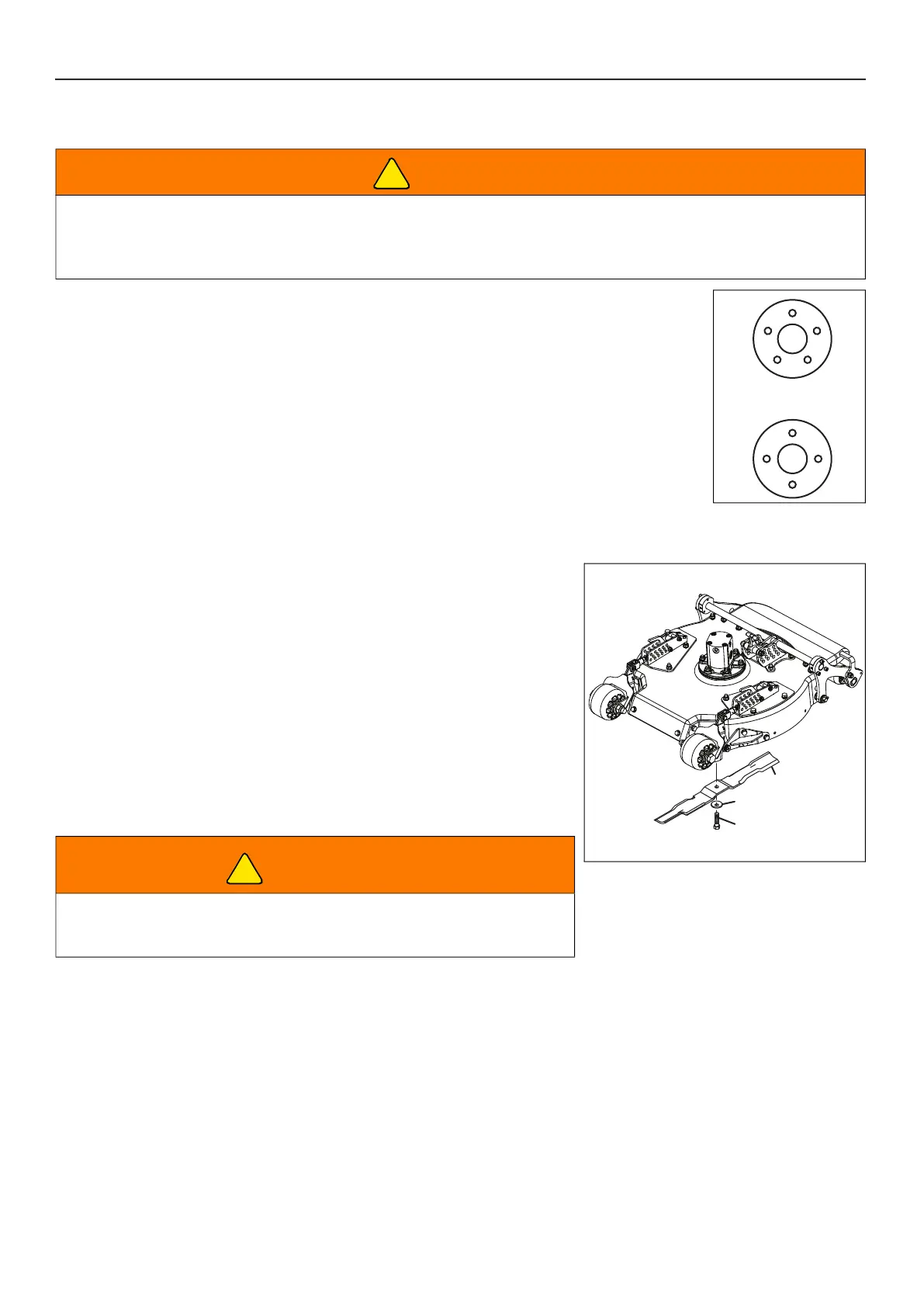

Tighten all hardware with your fingers, then torque hardware in the order shown. When

possible, tighten nuts in the top position.

Check and torque hardware each day until torque is kept at 85-95 ft.lb. (115-128Nm).

7.17 BLADE CHANGE __________________________________________________________

All Cutter Implements

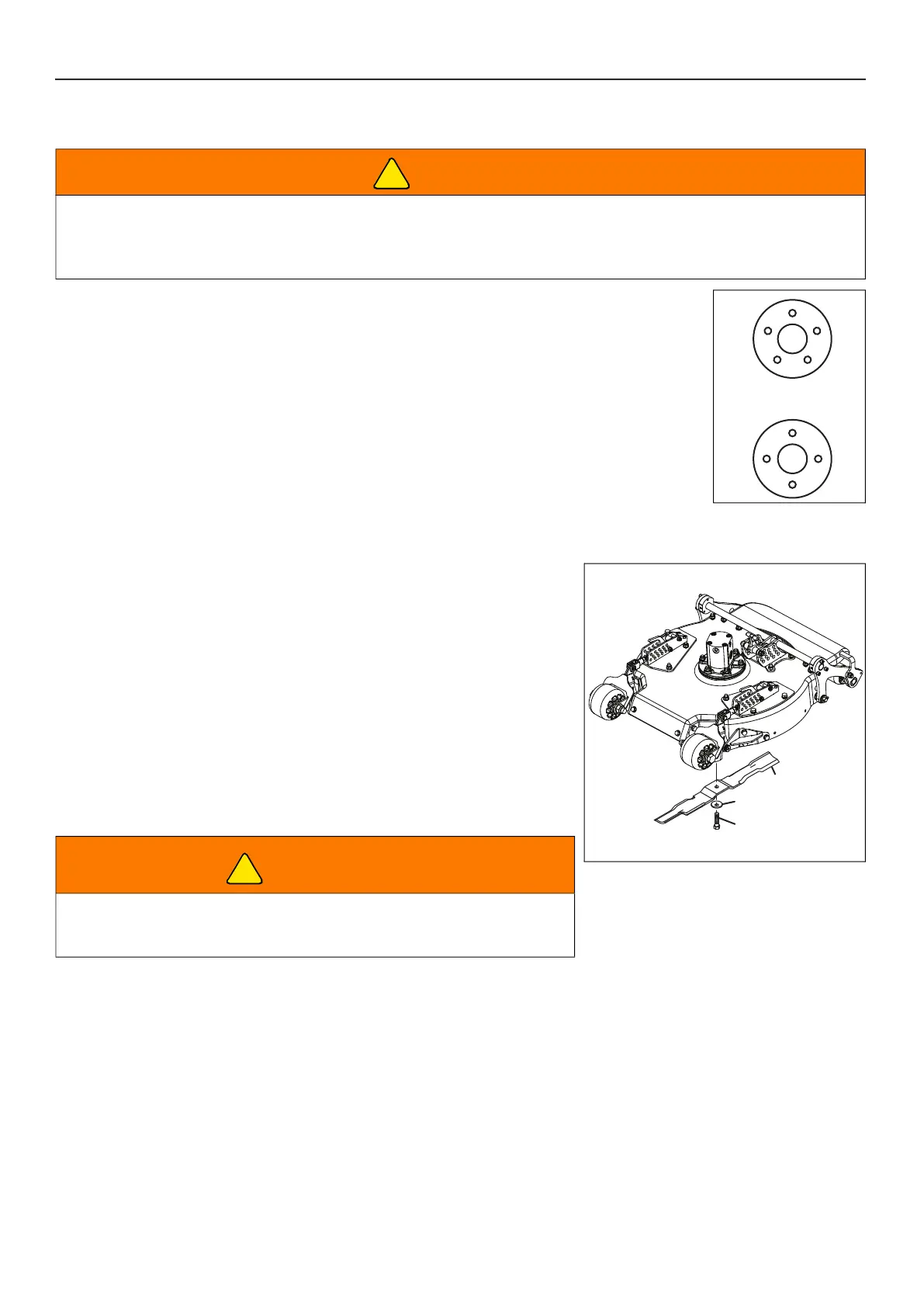

1. Start the engine and fully lift the cutting implements. Stop the engine

and remove the key.

2. If necessary, lift up on the front of the implement housing for better

access to the blade. Support the implement housing in this position.

3. Use a block of wood or other means to prevent the blade from turning.

4. Remove blade bolt (A) and washer (B).

5. Remove blade (C) from implement.

6. Fit new blade.

7. Assemble washer (B) and blade bolt (A) to motor spindle. The cupped

side of the washer must face the blade.

8. Use a block of wood or other means to prevent the blade from turning.

Torque the blade bolt to 95 ft-lb (129 Nm).

WARNING

Make sure the mower is parked on a solid and level surface. Never work on a mower that is supported only by the

jack. Always use jack stands.

If only the front or rear of the mower is lifted, put the chocks in front of and behind the wheels that are not lifted.

WARNING

Blades are extremely sharp and can cause severe cuts. For your

protection, hold blades with thick leather work gloves only.

!

1

2

3

4

1

2

3

4

5

!

Loading...

Loading...