Routine Maintenance

Tyres and Wheels

157 157

9811/5700-7

Changing a Wheel

!MWARNING

Deflate the tyre you wish to change before removing

the wheel from the machine. Air pressure in the tyres

can cause the tyre and rim sections to explode

causing serious injury or death. Never loosen the nuts

that hold the inner and outer wheel halves together

when there is air pressure in the tyre. Always wear

safety glasses.

12-6-1-3

!MWARNING

Whenever a wheel has been changed, check the nut

torques every two hours. When the nuts stay tight for

eight hours, the interval for checking can revert to the

period stated in the servicing schedule.

12-6-1-4

Note: If for whatever reason a wheel bolt is renewed, all

the bolts for that wheel must be replaced as a set, since the

remaining bolts may have been damaged.

1 Remove the wheel as follows:

a Park the machine on firm level ground.

b Apply the park brake and select neutral.

c Stop the engine and remove the ignition key.

d Jack up the machine to gain access to whichever

wheel you wish to change.

e Deflate the tyre and remove the valve core to

make sure that all the air is out of the inner tube

(pneumatic tyres only).

Note: Push a wire through the valve stem to make sure the

valve stem does not have a restriction.

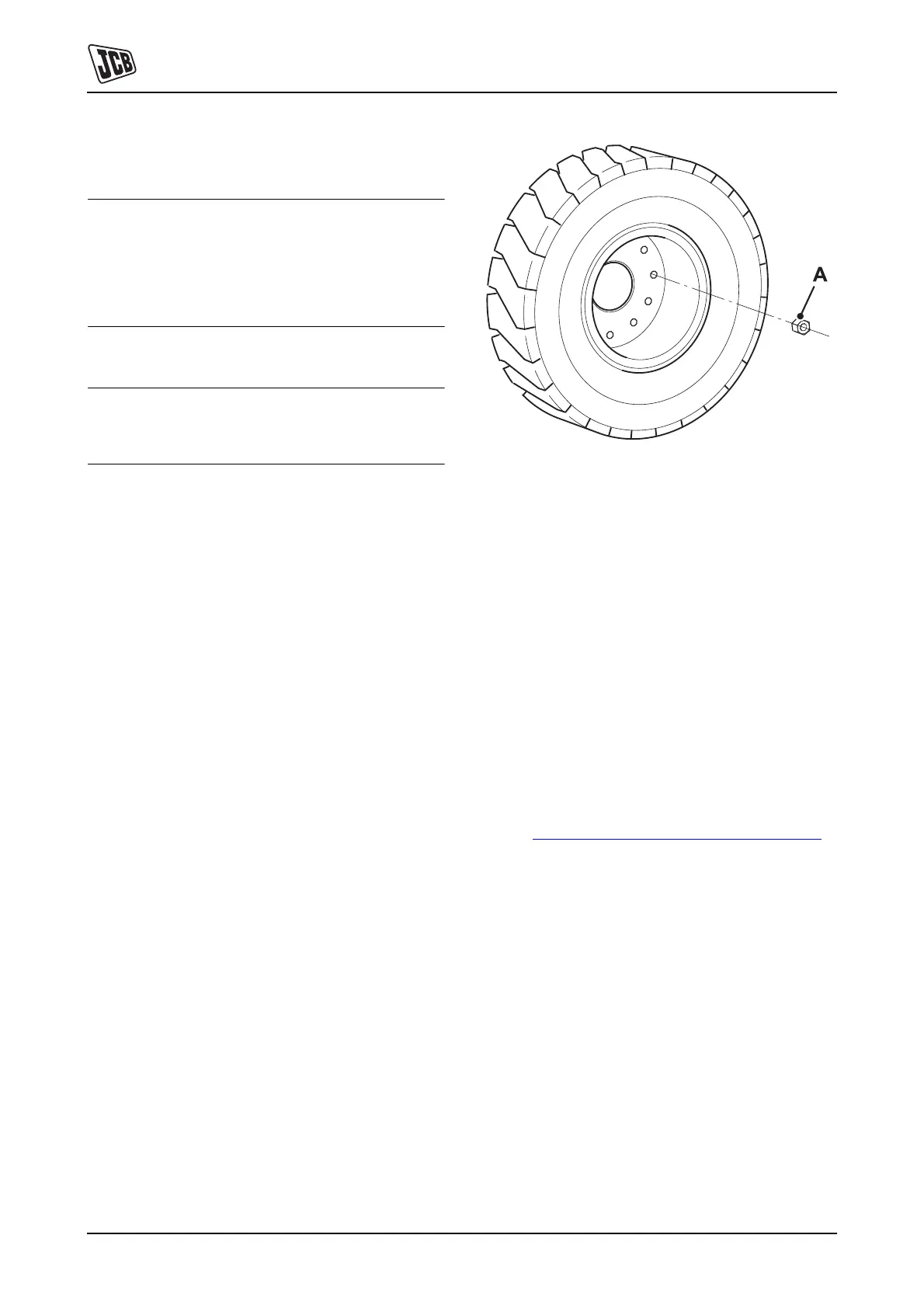

f Remove the nuts A then remove the wheel.

Fig 124.

2 Refit the wheel as follows:

a Inspect the wheel for any damage, i.e. elongated

holes.

b Clean the hub, wheel mounting face and nut

cones thoroughly if they are contaminated with

paint, rust or debris.

c Ensure the wheel stud thread surface is

maintained dry and is free from all lubricants.

d Position the wheel on the hub.

e Lightly tighten the nuts A to ensure the wheel is

correctly seated onto the hub.

f Tighten the nuts A diametrically in pairs.

K

Checking the Wheel Nut Torques ( T 158).

g Lower the machine to the ground.

274820-V1