Routine Maintenance

Forks

159 159

9811/5700-7

Forks

Inspecting the Forks

!MWARNING

Do not try to correct the alignment of the fork tips by

bending the forks or adding shims. Never repair

damaged forks by heating or welding. Forks are made

of special steel using special procedures. Always

replace damaged forks.

12-5-1-6

1 Park the machine on level, solid ground.

2 Make sure the park brake is engaged and select

neutral.

3 Raise the forks to allow inspection.

4 Stop the engine and remove the key.

5 Inspect the forks as follows:

a Make sure there are no cracks or obvious damage

such as twisting or bending.

b Inspect the heel of the forks for wear. Wear must

not exceed 10% of the fork thickness.

c Check that the fork tips are aligned. Tip alignment

must be within 3% of the fork length.

d Check the angle of the fork upright to the fork

plate. The angle must not exceed 93 degrees.

Changing the Forks

!MWARNING

The forks are heavy. Make sure suitable lifting

equipment is used to support and transport them.

12-5-1-7_2

1 Park the machine on level, solid ground.

2 Apply the park brake and select neutral.

3 Depending on the fork type fitted, remove each type

of fork as follows:

Industrial Carriage Forks

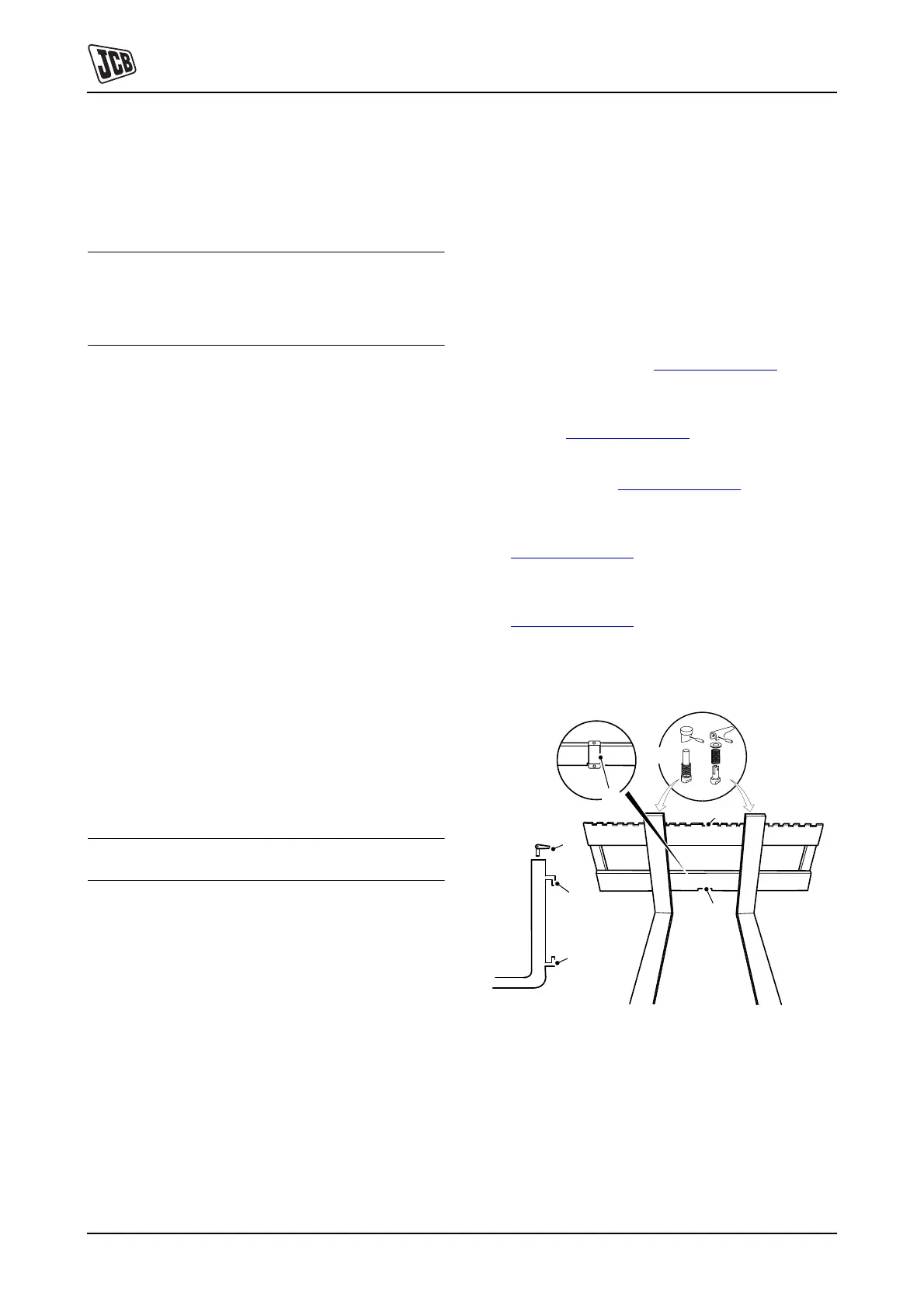

Note: The locking clamp X is only required when the

individual fork width is less than 125mm (5in). Contact your

JCB dealer to procure and install a locking clamp if

required.

Removal

1 If installed, remove the locking clamp X from the

bottom of the carriage. K

Fig 126. ( T 159)

2 Release locking pins A and slide the fork to the centre

of the carriage so it is level with the bottom removal

notch C. K

Fig 126. ( T 159)

Note: Your machine will have either twist and pull or pull

type fork locking pins. K

Fig 126. ( T 159)

3 Lower the forks onto blocks so that the bottom hook

B disengages from the bottom removal notch C.

K Fig 126. ( T 159)

4 Lower the carriage further so that the upper hook D

disengages from the top of the carriage E.

K

Fig 126. ( T 159)

5 Move the carriage away from the forks or support and

remove the forks using suitable lifting equipment.

T069860-1

Fig 126.

Loading...

Loading...