❺

❶

❹

G

H

F

E

D

C

A

B

❻

❶

❸

❾

❽

[DDL-8000A-PMS]

❷

[DDL-8000A-PSH]

❻

❶

❸

❷

❾

❽

B

A

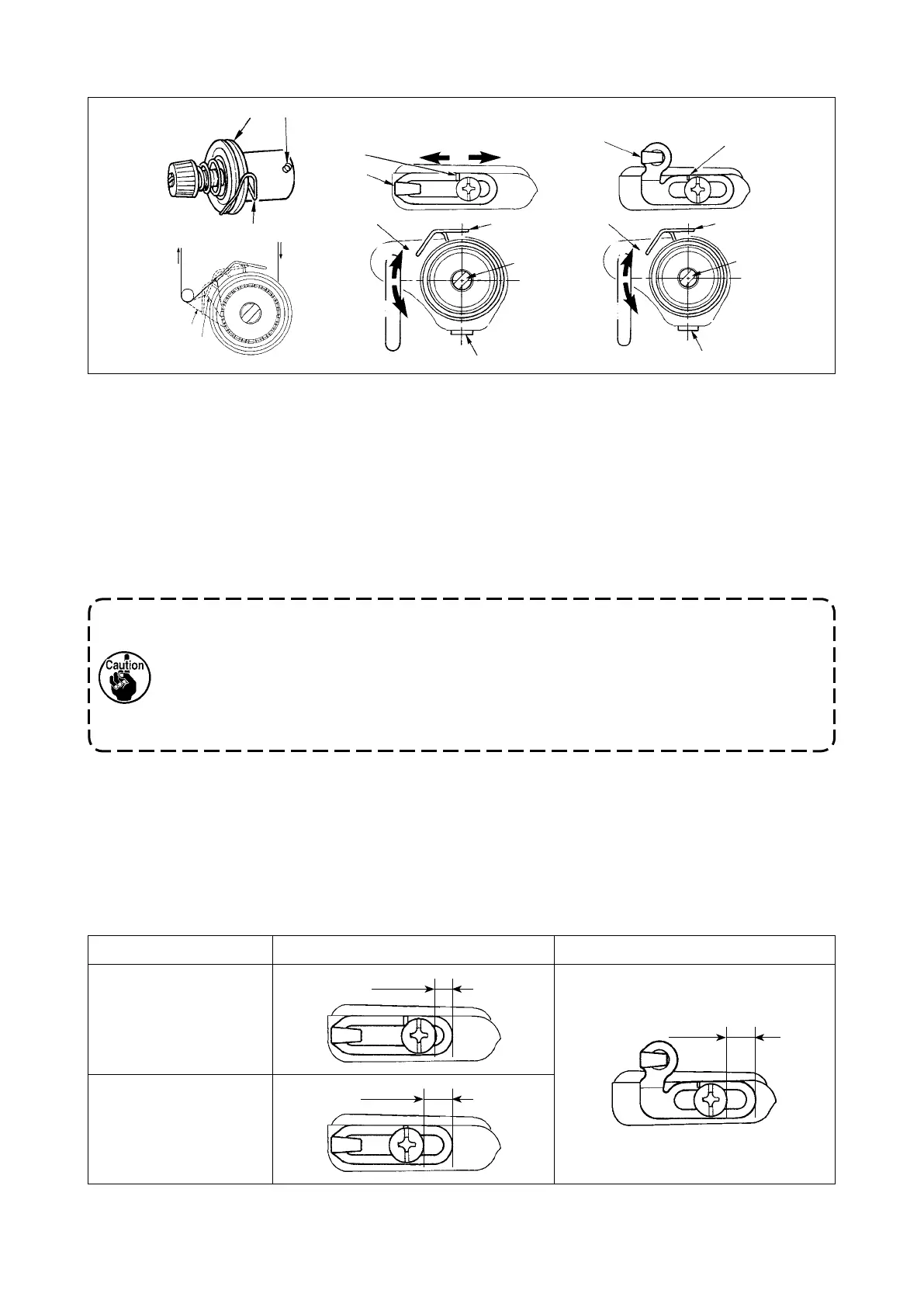

[DDL-8000A-PMS] [DDL-8000A-PSH]

< Destination AA and BB >

4mm

7mm

< Destination GG >

7mm

– 21 –

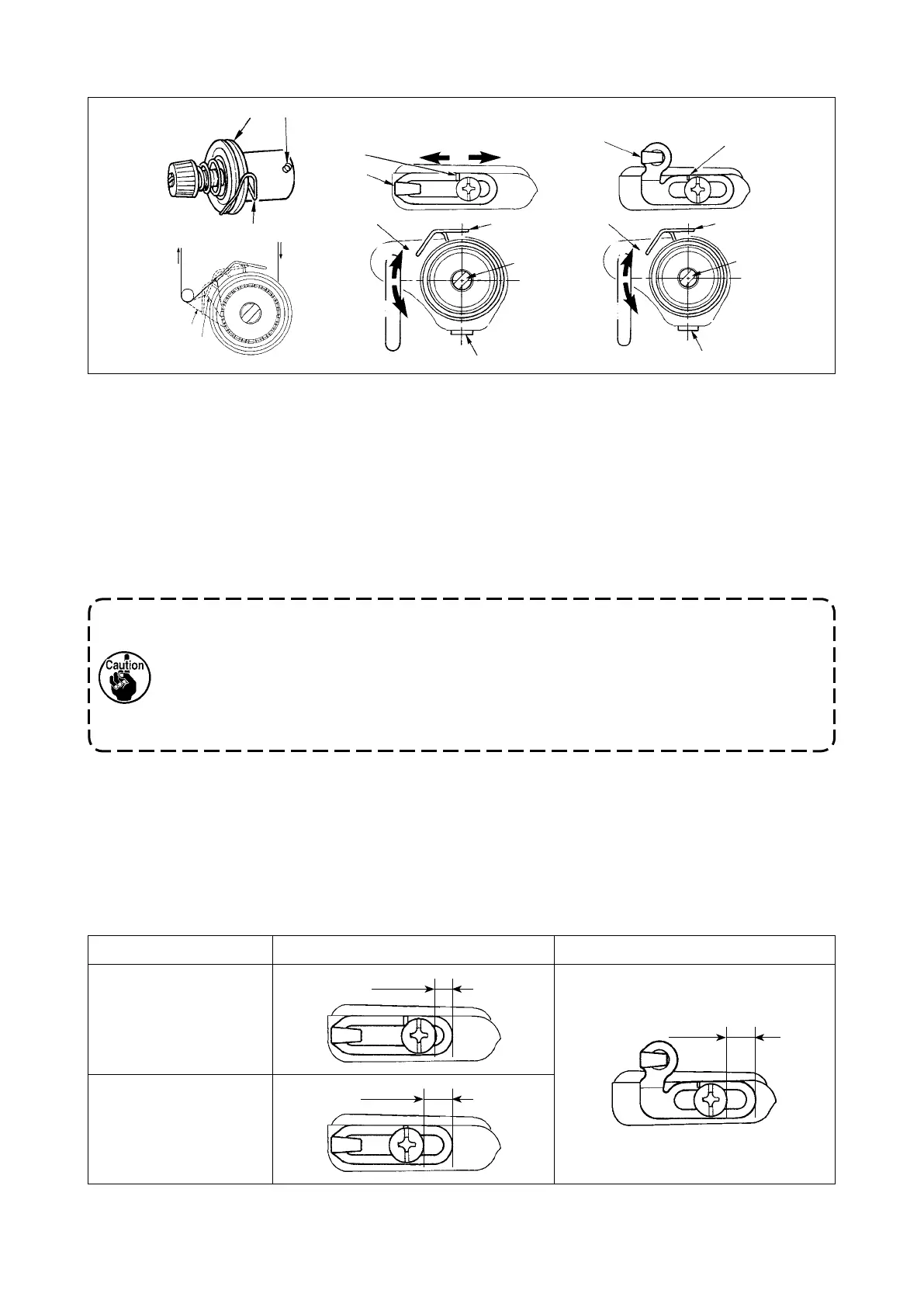

3-12. Adjusting the thread take-up spring and the thread take-up stroke

(1) Adjusting the stroke of thread take-up spring

❶

1) Loosen setscrew

❷

.

2) Turn tension post

❸

clockwise (in direction

A

), the stroke of the thread take-up spring will be increased,

and turn the post

❸

counterclockwise (in direction

B

), the stroke will be decreased.

(2) Adjusting the pressure of thread take-up spring

❶

1) Loosen setscrew

❷

, and remove thread tension (asm.)

❺

.

2) Loosen tension post setscrew

❹

.

3) Turn tension post

❸

clockwise (in direction

A

), the pressure will be increased, and turn the post

❸

coun-

terclockwise (in direction

B

), the pressure will be decreased.

(3) Adjusting the thread take-up stroke

1) When sewing heavy-weight materials, move thread guide

❽

to the left (in direction

C

) to increase the

length of thread pulled out by the thread take-up.

2) When sewing light-weight materials, move thread guide

❽

to the right (in direction

D

) to decrease the

length of thread pulled out by the thread take-up.

* Standard state of the thread guide

The standard distance between the right end face of thread guide and the screw head is as follows:

To check how the thread take-up spring works, draw out the needle thread in direction

F

after

having adjusted the thread take-up spring pressure to check whether the thread take-up spring

exerts force to the thread up to the last moment (state

G

) just before the thread comes out

from

E

. If the spring fails to exert force to the spring until the last moment (state

H

), decrease

the thread take-up spring pressure. In addition, the stroke of the thread take-up spring is exces-

sively small, the spring does not work properly. For the general fabrics, a stroke of 10 to 13 mm

is proper.

Loading...

Loading...