❻

❺

❼

❹

❸

D

E

❶

❷

A

B

C

Turn thread trimming cam

❸

in the direction of

arrow until the outer periphery of thread trimming

cam groove

C

comes in contact with roller

❷

and

stops. At this position, x thread trimming cam

setscrew

❼

.

Illustration as observed from

D

(right side face)

❷

C

❸

❹

❷

C

Correct (

F

)

❷

C

Wrong (

G

)

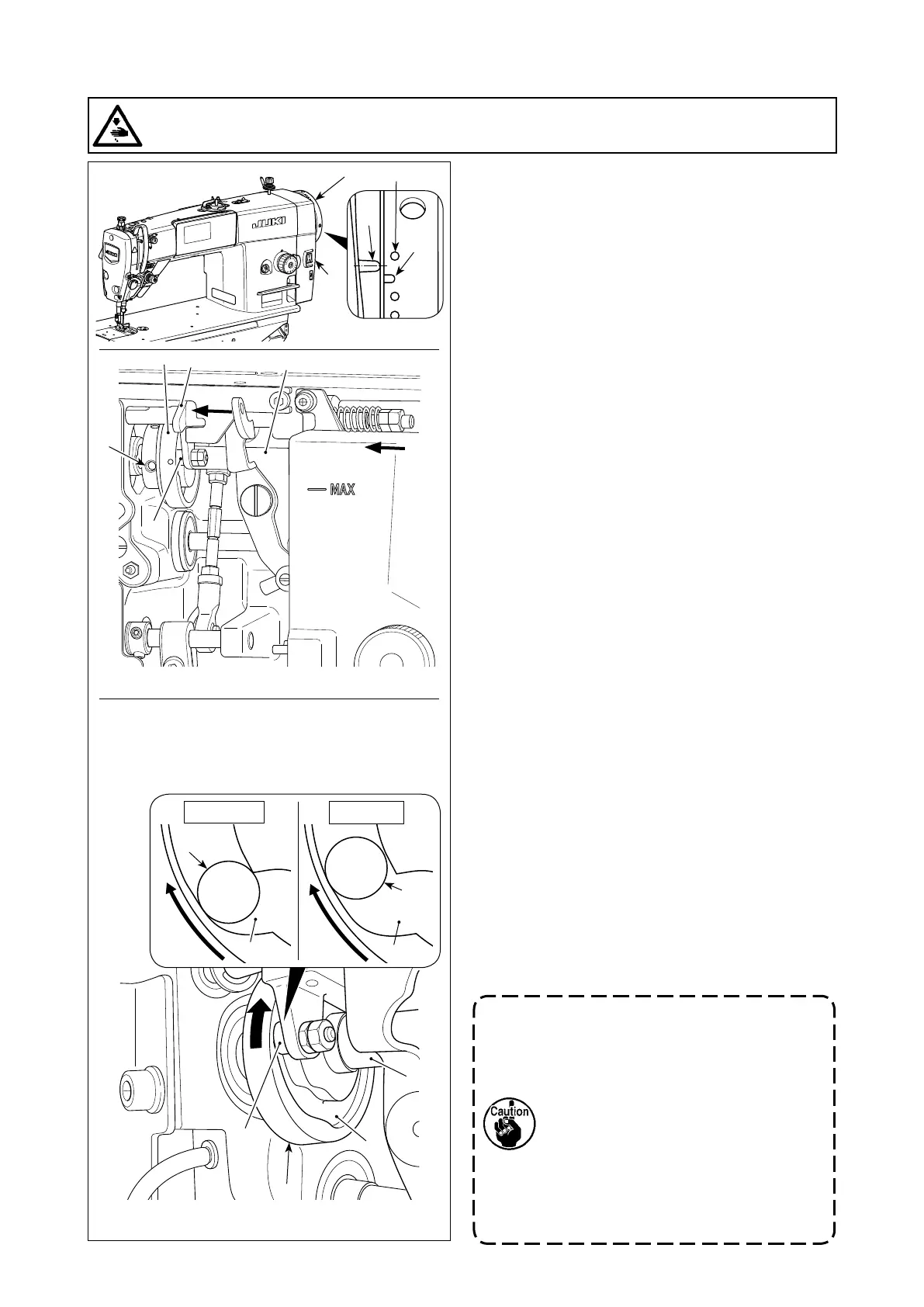

5-3. Adjusting the thread trimmer

5-3-1. For checking of the thread trimming

cam timing

The purpose of the adjustment of the thread trim-

ming is to bring marker line

A

on electrical box

cover

❺

to the portion between the colorless marker

dots

B

and

C

on handwheel

❻

.

1) Tilt the sewing machine head.

2) Turn handwheel

❻

by hand in the normal direc-

tion of rotation until the thread take-up lever goes

up slightly below the upper dead point. Press cam

follower

❶

with ngers to the left (in direction of

arrow

E

) to t roller

❷

to in groove

C

in thread

trimming cam

❸

.

3) In this state, turn handwheel

❻

in the direc-

tion which is opposite to the normal direction of

rotation until handwheel

❻

will go no further. (If

the handwheel is turned further, it reaches the

position at which cam follower

❶

starts moving.)

At this time, adjust so that the marker line

A

on

electrical box cover

❺

is brought to the portion

between the colorless marker dots

B

and

C

on

handwheel

❻

.

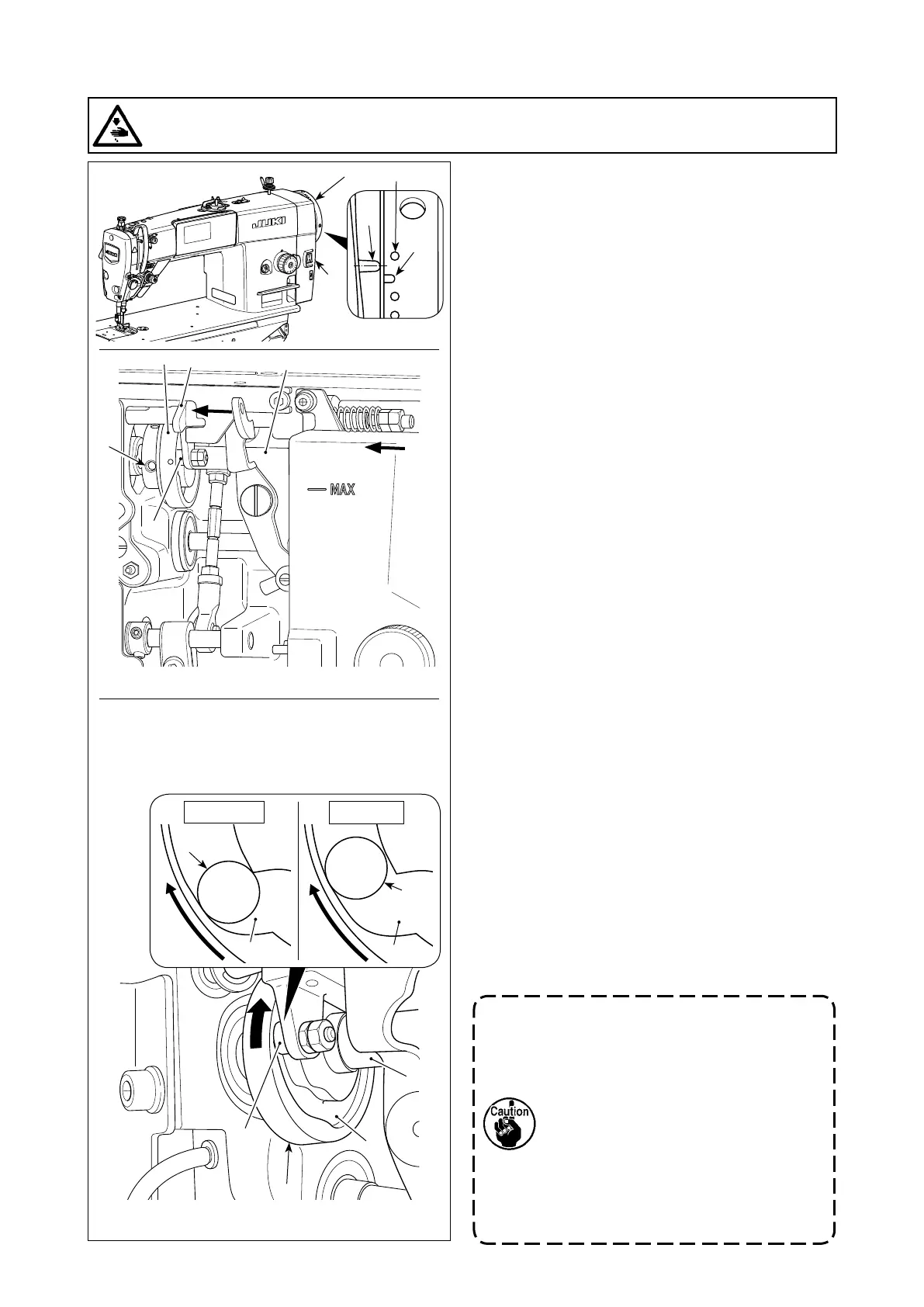

5-3-2. Adjustment of the thread trimming

cam timing

1) Tilt the sewing machine head.

2) Loosen the screws No.1 and No. 2 of thread trim-

ming cam setscrew

❼

in the written order.

3) Align marker line

A

on electrical box cover

❺

with the colorless marker dot

B

on handwheel

❻

.

4) Pressing cam follower

❶

to the left (in the direc-

tion of arrow

E

), engage thread trimming cam

❸

with roller

❷

. Then, turn only thread trimming

cam

❸

with ngers in the direction which is op-

posite to the normal direction of rotation of feed

driving shaft

❹

until it will go no further without

turning feed driving shaft

❹

. At this position,

tighten the screws No. 1 and No. 2 of thread trim-

ming cam setscrew

❼

in the written order while

pressing thread trimming cam

❸

against roller

❷

.

The alignment point between thread

trimming cam

❸

and roller

❷

is position

(

F

) from which cam follower

❶

starts

moving. Position (

G

) at which you feel

that thread trimming cam

❸

comes in

contact with roller

❷

for the rst time

during adjustment is not the correct

alignment position.

*

Be sure to correct the thread trimming

cam timing carefully since it largely

aects the loop spreading timing.

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

– 56 –

Loading...

Loading...